Multi-stage continuous tea fragrance-enhancing machine and control method thereof

A tea aroma enhancer and tea technology, applied in the direction of tea spices, etc., can solve the problems of weak penetration ability, low degree of automation, and fragile tea, so as to ensure the stability of movement, improve the quality and aroma, and not easy to deform and slip Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

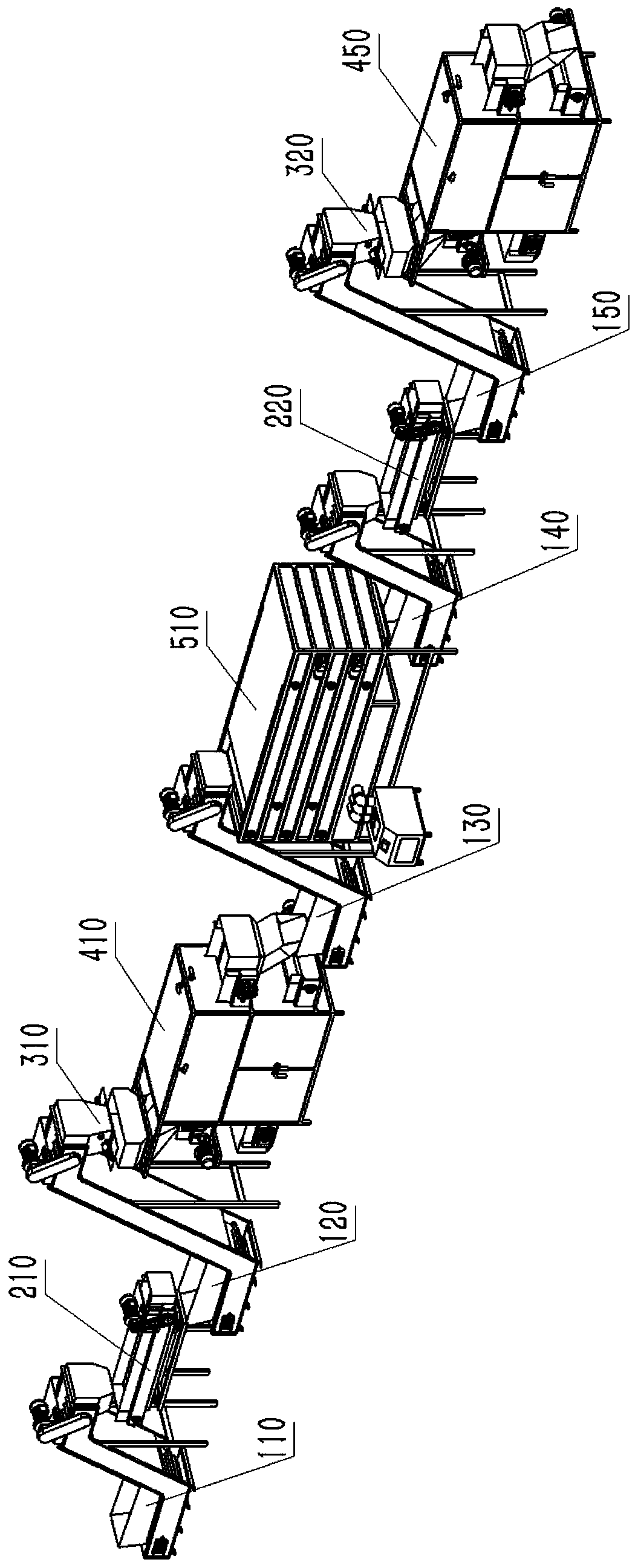

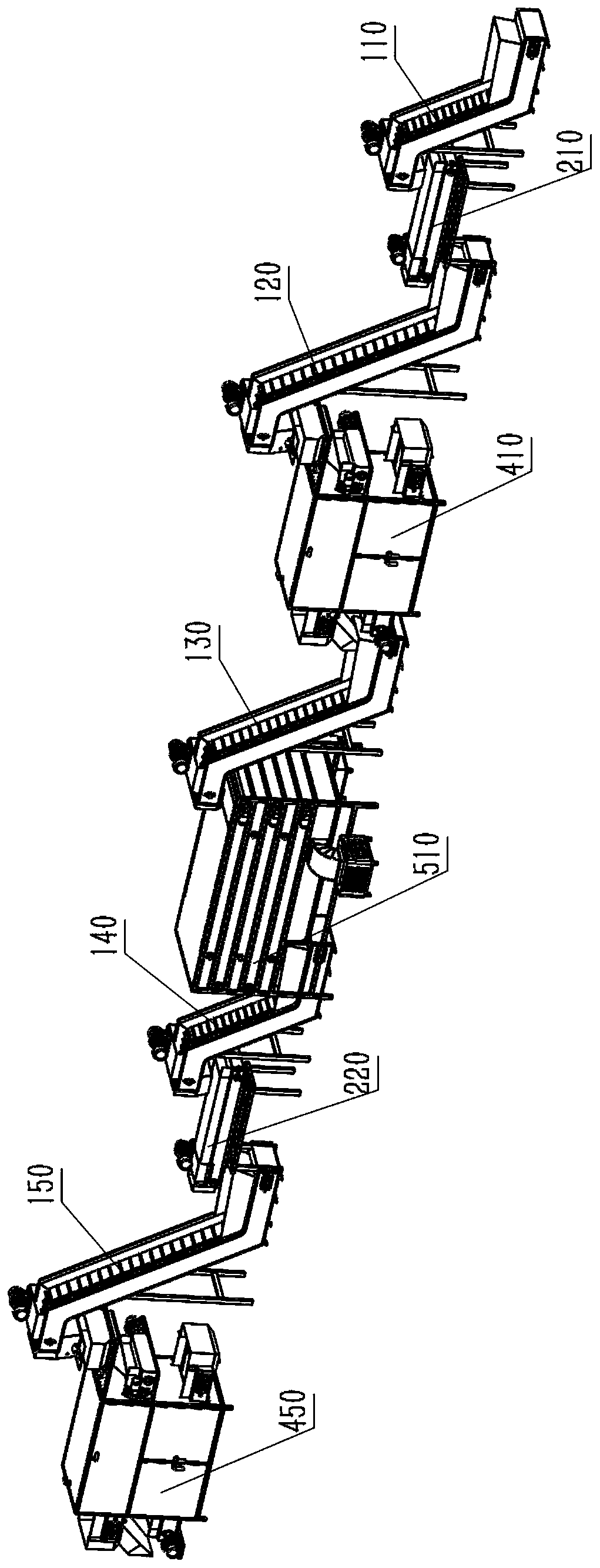

[0068] Such as figure 1 , 2 Shown: a multi-stage continuous tea aroma extractor, including a PLC control unit and an initial aroma supply unit, an initial aroma enrichment unit, a cooling feeding unit, a cooling unit, and a secondary aroma enhancement unit arranged in sequence along the tea processing direction Feeding unit, re-increasing unit;

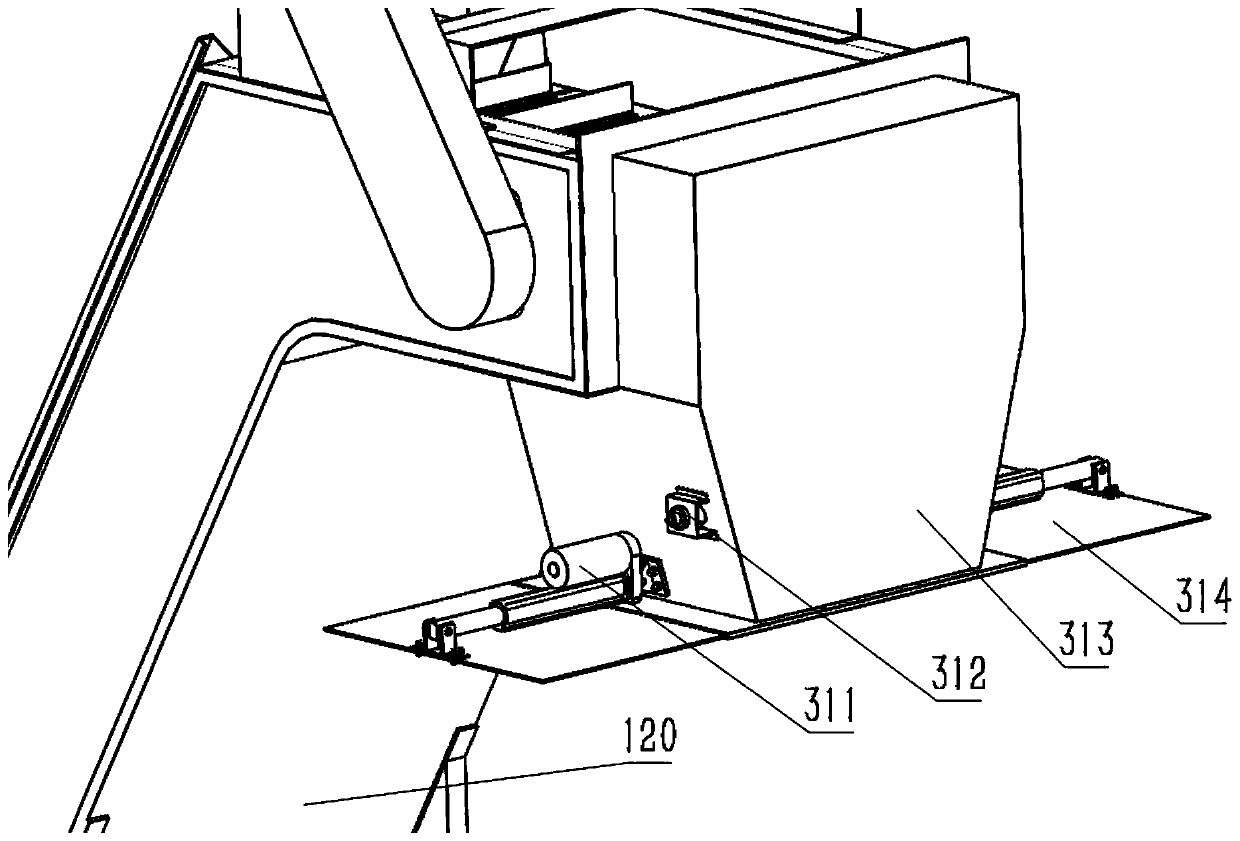

[0069] The first fragrance-raising unit includes the first vertical conveyor 110, the first weighing conveyor 210 and the second vertical conveyor 120 arranged in sequence along the tea leaves conveying direction; the first fragrance-raising unit includes the first tealeaves Fragrance enhancing machine 410; the end of the second vertical conveyor 120 is provided with a storage device 1 310 that automatically feeds into the first tea aroma enhancing machine 410;

[0070]The cooling feeding unit includes a thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com