Energy-saving and environment-friendly garbage collection automatic auxiliary device

A technology of garbage collection, energy saving and environmental protection, applied in the direction of garbage collection, trash can, waste collection and transfer, etc., can solve the problems of insufficient energy saving and environmental protection, time-consuming and labor-intensive, etc., and achieve the effect of simple structure, convenient use, and reliable and efficient collection work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

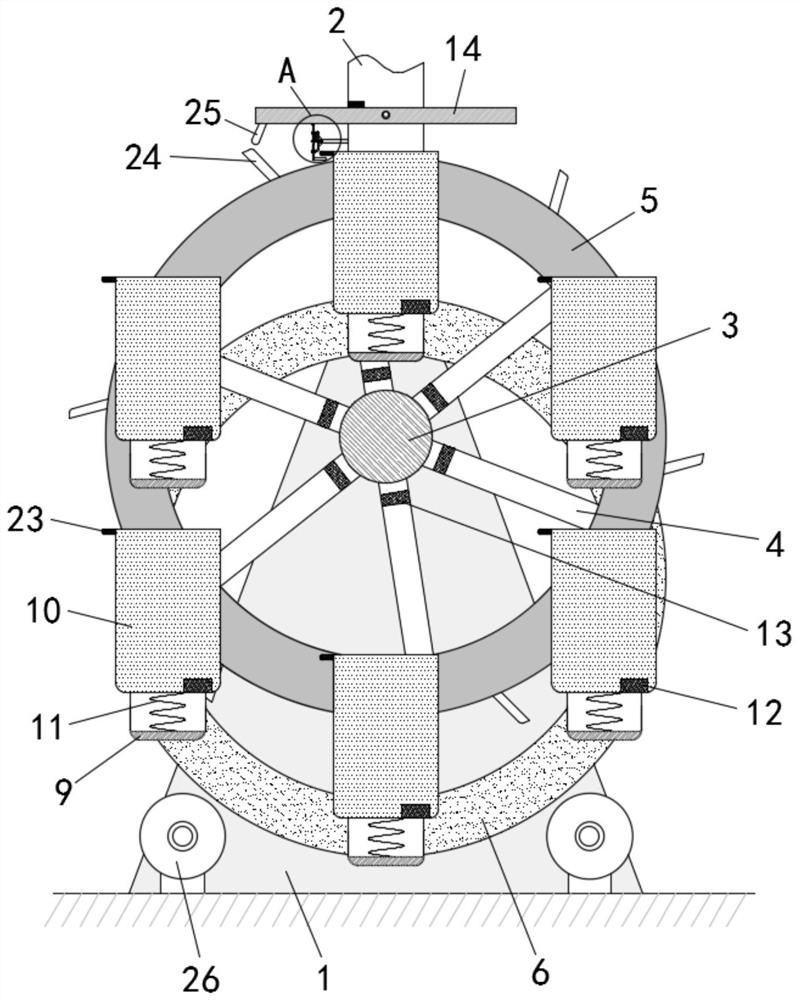

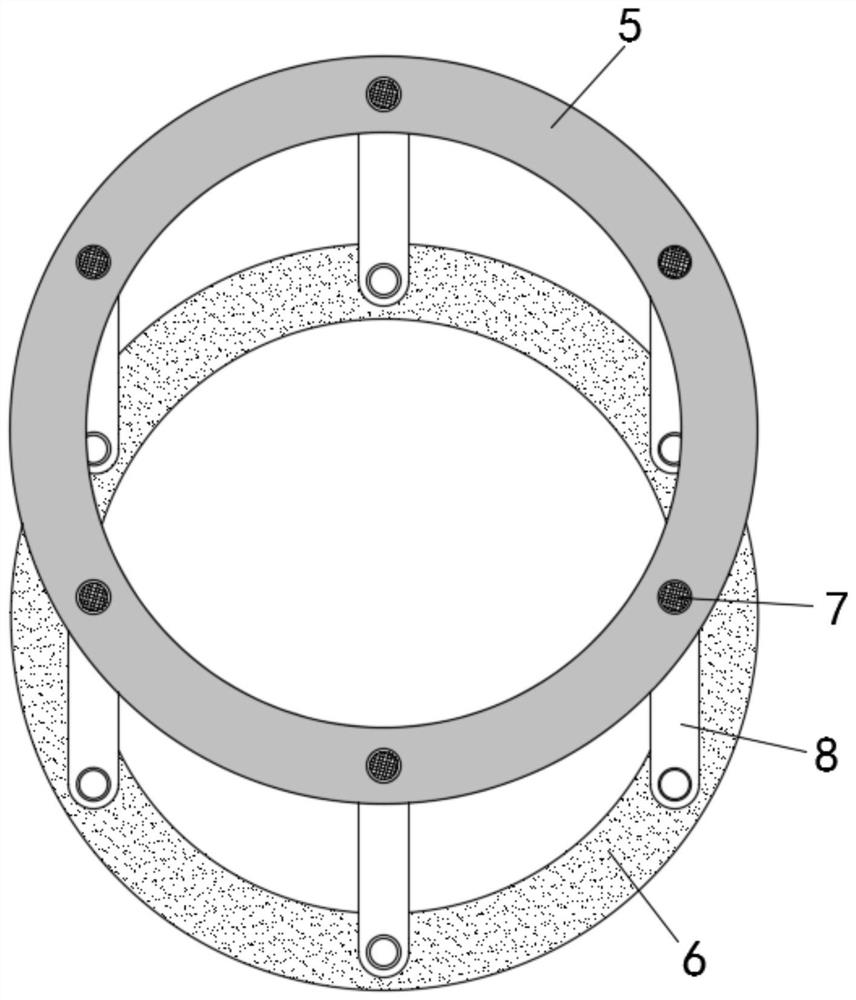

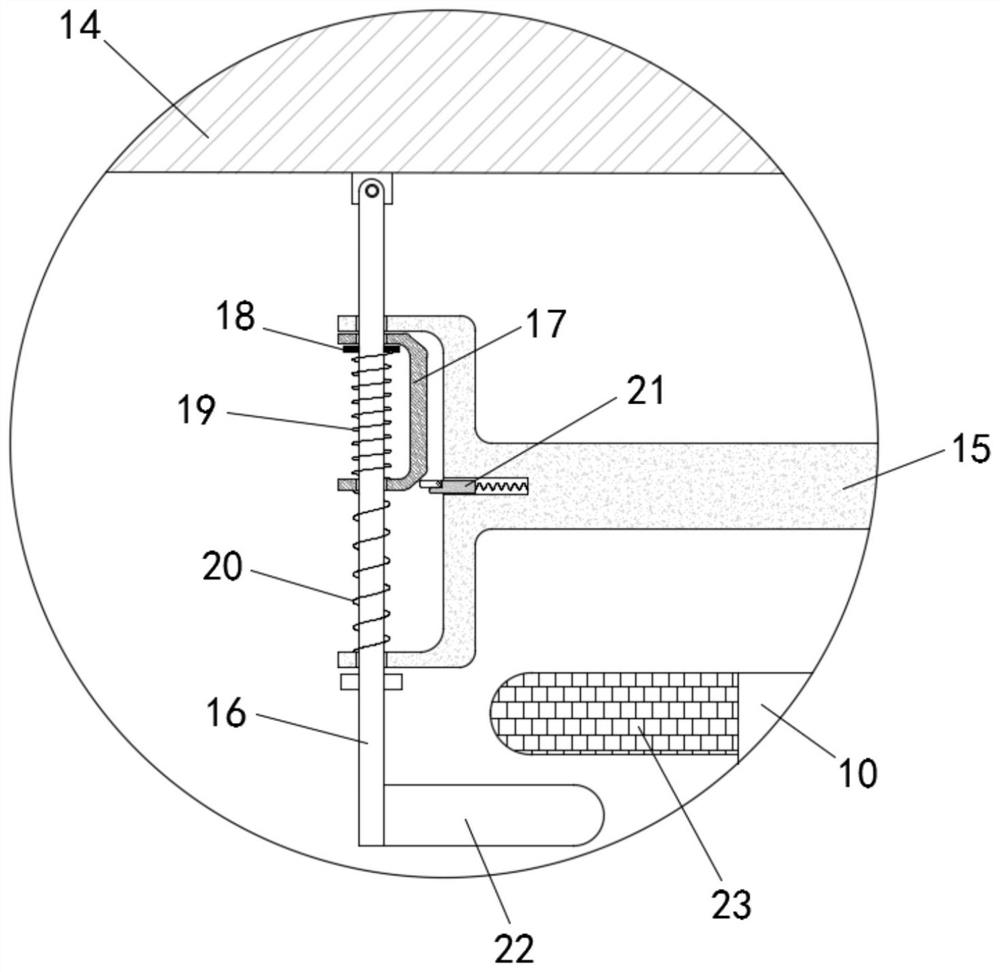

[0029] as attached figure 1 to attach Figure 4 Shown:

[0030] The present invention provides an energy-saving and environment-friendly automatic auxiliary device for garbage collection, which includes a base 1, which is fixedly installed under the feeding port 2, and a rotating shaft 3 is installed on the front of the base 1, and the outer side of the rotating shaft 3 is fixedly socketed through a connecting rod 4 There is a main ring 5, the front of the base 1 and the back side of the main ring 5 are rotatably equipped with a secondary ring 6, the front of the base 1 is provided with supporting wheels 26 supporting the secondary ring 6, and the inside of the main ring 5 is movably inserted with evenly distributed Cylinder 7, the back of column 7 is movably connected with secondary ring 6 through hinge plate 8, and the front of column 7 and the front that is positioned at main ring 5 are fixedly connected with vertical seat 9, and the inside of vertical seat 9 is slidingly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com