An energy-saving and environment-friendly automatic auxiliary device for garbage collection

A garbage collection, energy saving and environmental protection technology, applied in the direction of garbage collection, garbage bins, waste collection and transfer, etc., can solve the problems of time-consuming and labor-intensive, insufficient energy saving and environmental protection, etc., and achieve the effect of convenient use, simple structure, reliable and efficient collection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

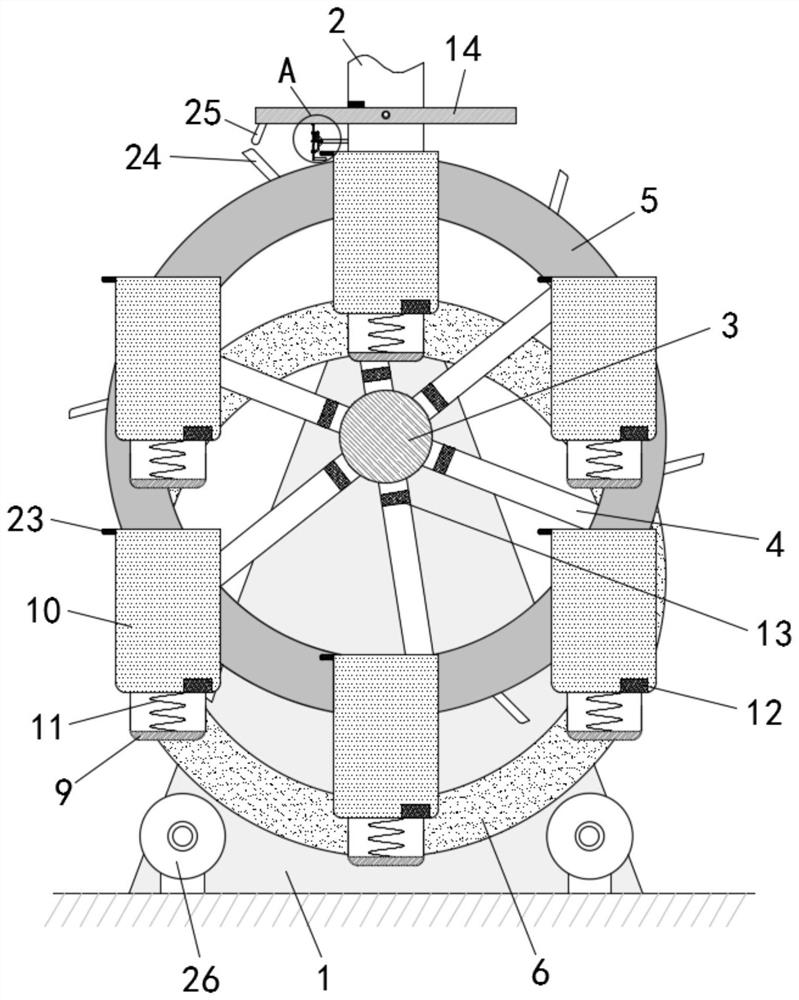

[0029] Append figure 1 Attachment Figure 4 Looking:

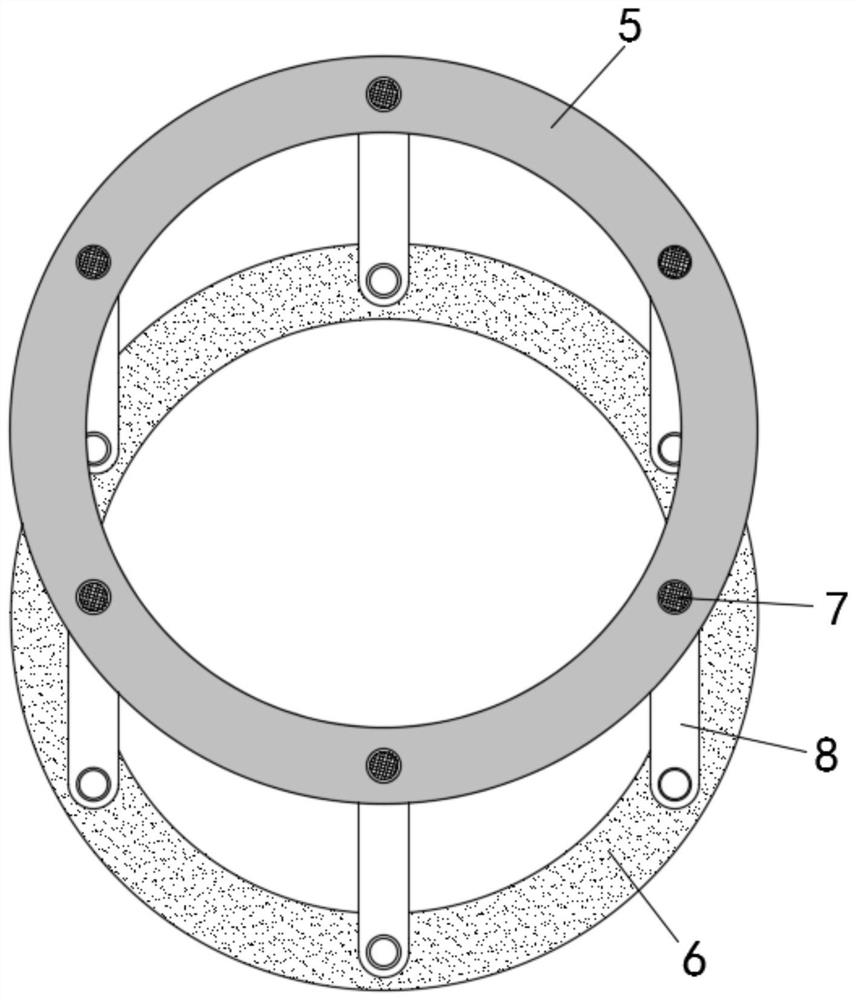

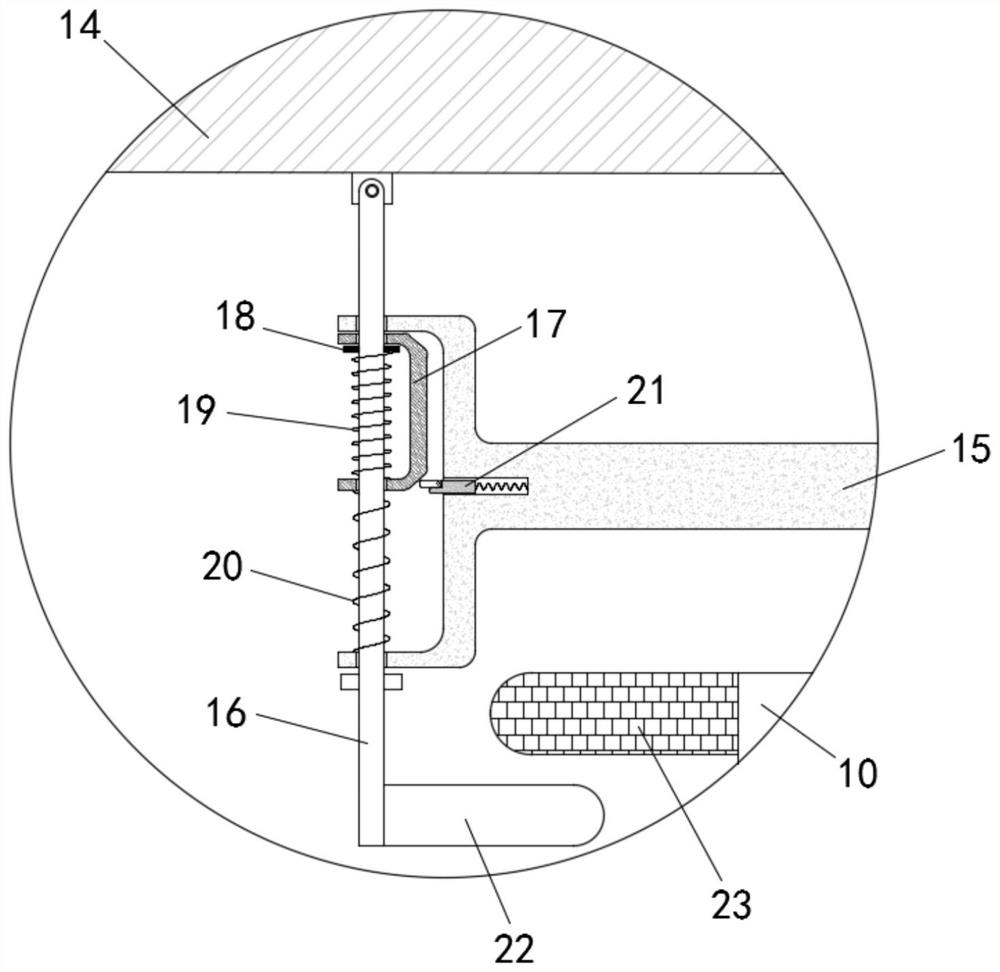

[0030] The present invention provides an energy-saving garbage collection automation auxiliary device, including a base 1, and the base 1 is fixedly mounted below the lower body opening 2, and the front side of the base 1 is rotated and mounted with a rotating shaft 3, and the outer side of the rotating shaft 3 is fixed to secure socket. There is a primary ring 5, the front side of the base 1 is rotated on the back side of the main ring 5, and the front surface of the base 1 is provided with a support wheel 26 supporting the sub-ring 6. The internal activity of the main ring 5 is uniformly distributed. The column 7, the back surface of the cylinder 7 is connected to the sub-ring 6, and the front surface of the cylindrical 7 is fixed to the front side of the main ring 5, and the vertical seat 9 is slidably mounted, and the gathering box 10, collecting box 10 The bottom of the 10 is attached, and the front surface of the collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com