Cross-flow filtration system including particulate settling zone

A cross-flow filtration and particle sedimentation technology, applied in the feeding/discharging device of the sedimentation tank, sedimentation tank, filtration and separation, etc., can solve the problem of easy scaling and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention includes cross-flow filtration systems for separating particulate matter from liquids and methods of utilizing such systems. The term "system" refers to an interconnected assembly of components. In one embodiment, the present invention combines cross-flow filtration and particle settling within a pressurized recirculation loop. Particle settling may include flotation or settling based on the density difference of the particles and water. In a preferred embodiment, the system also incorporates cyclonic separation.

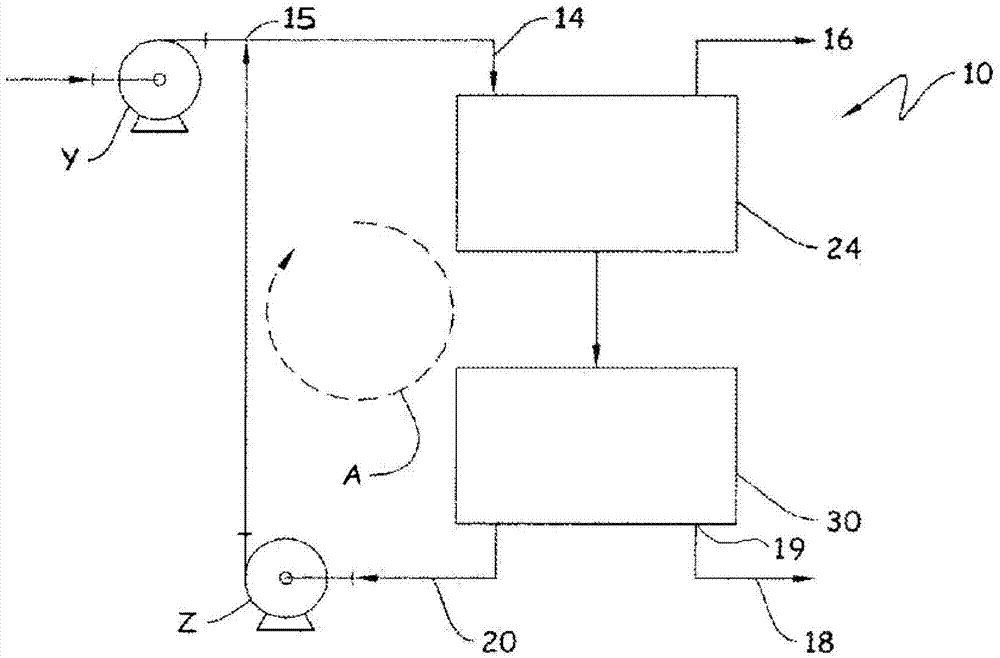

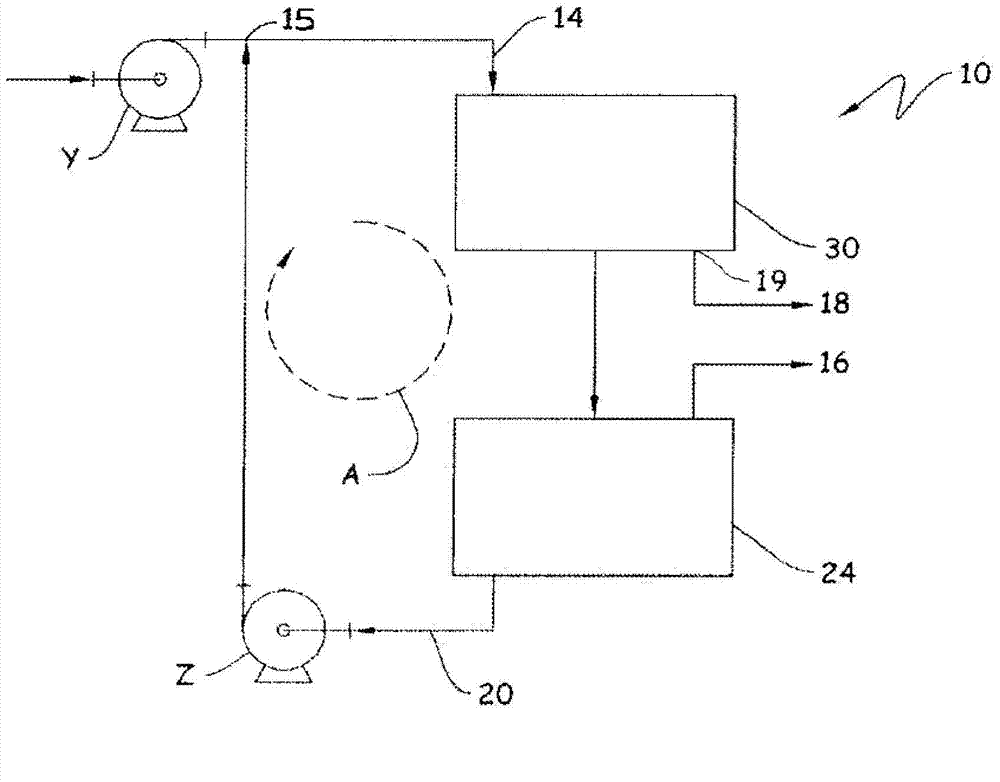

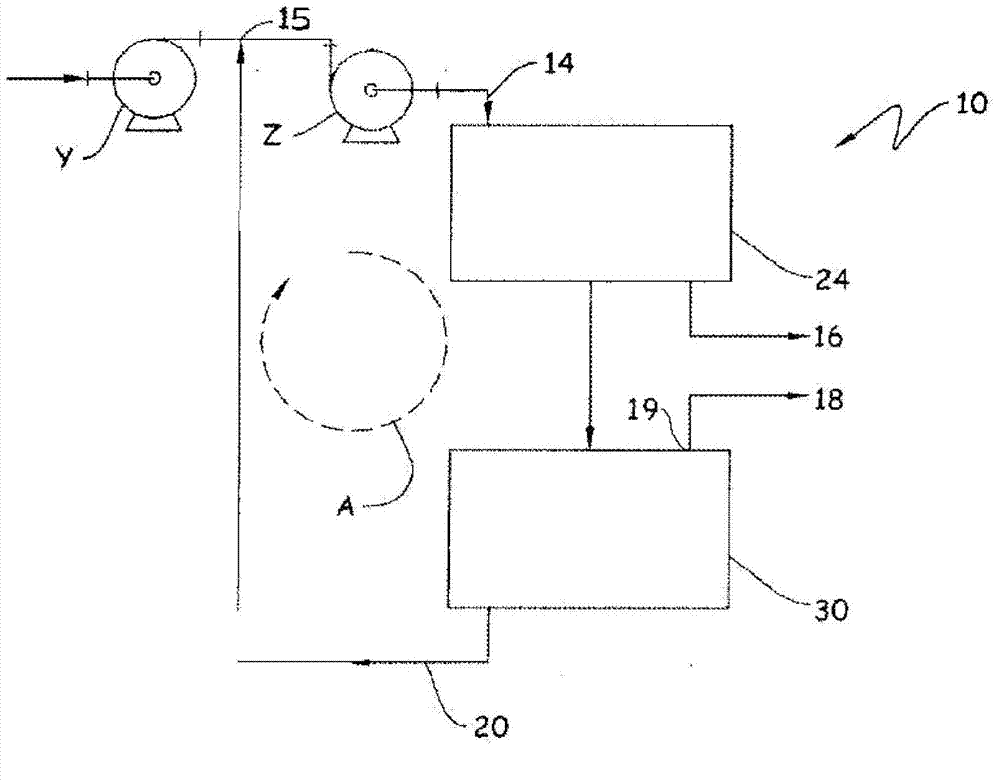

[0018] Representative systems (10) in Figure 1A - Schematically shown in -F, which includes a pressurizable cross-flow filtration zone (24) in fluid communication with the particle settling zone (30). As the name implies, cross-flow filtration occurs in the cross-flow filtration zone (24), for example by passing the feed fluid over the membrane surface. Similarly, particle settling occurs in the particle settling zone (30). Zones (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com