Valve unit with axial pressure medium inlet

A pressure medium, axial technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of hindering the movement of the valve piston and the intrusion of dirt particles, and achieve the effect of simple design scheme and cheap design scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

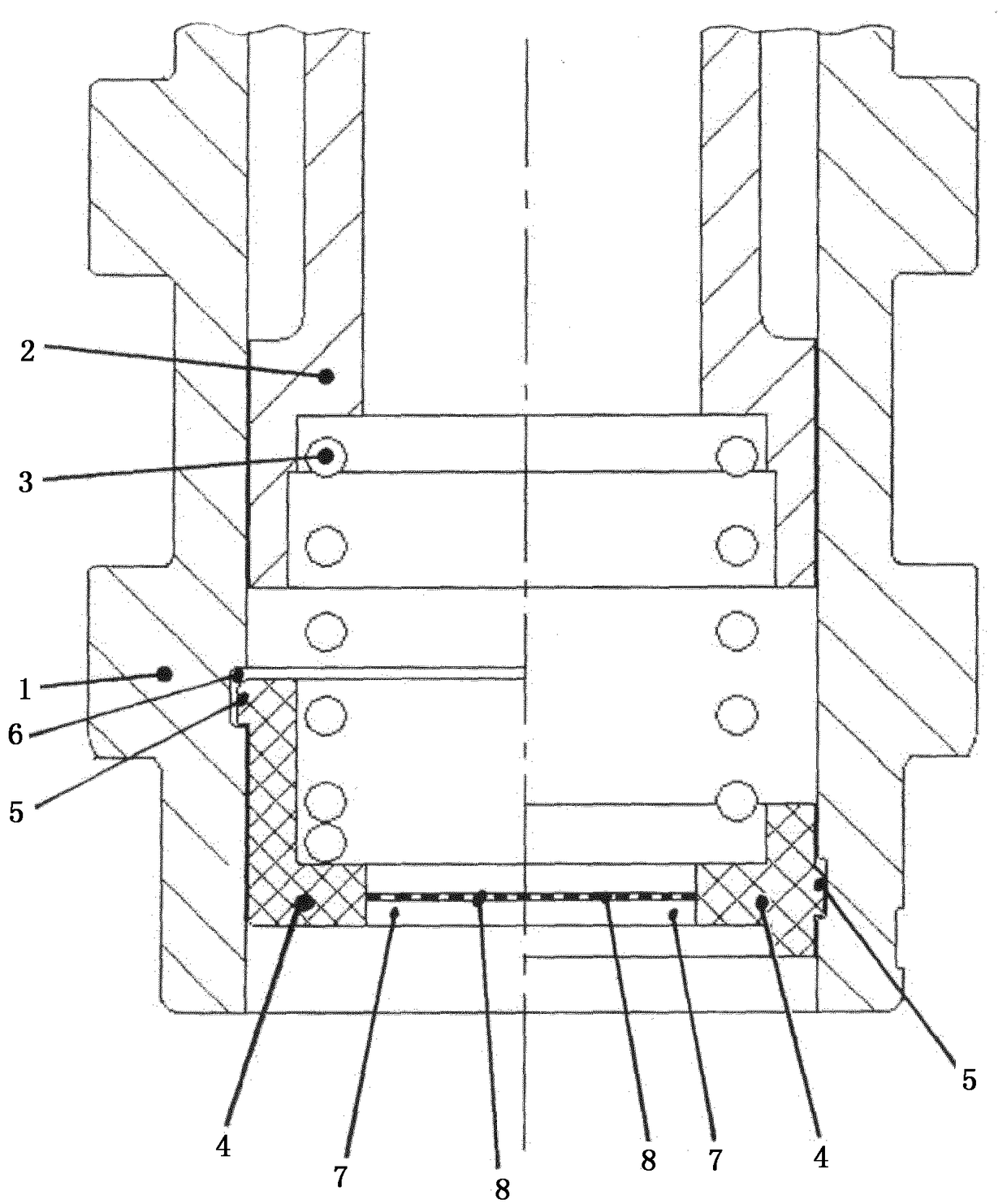

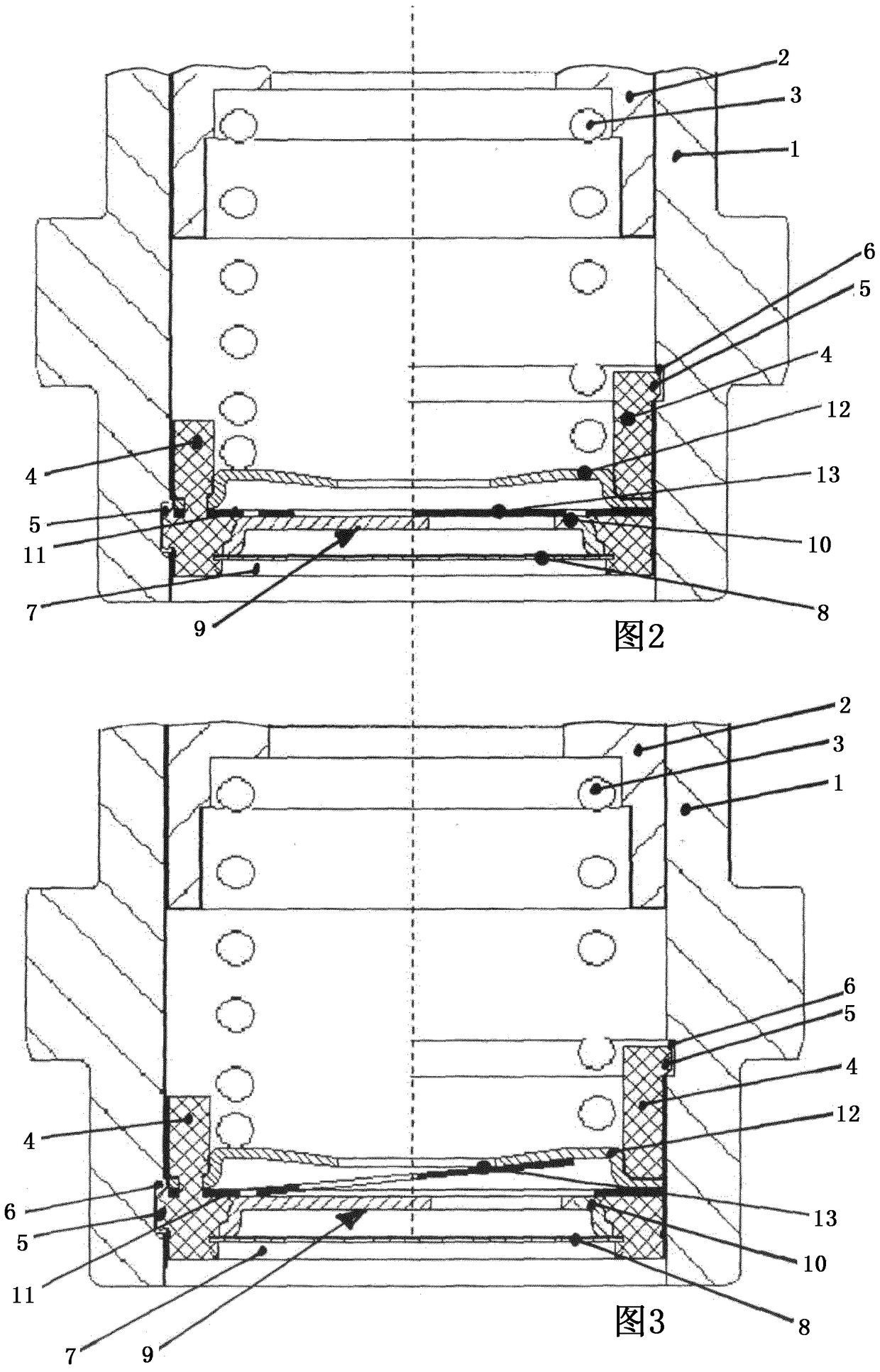

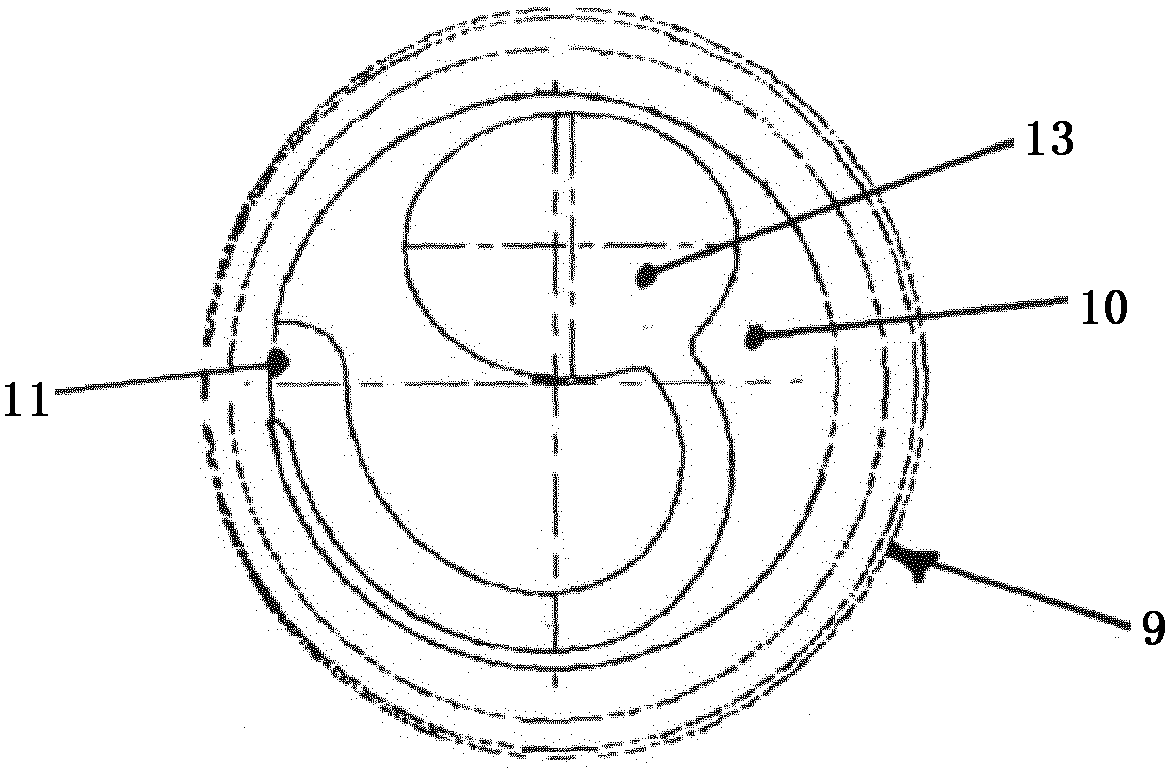

[0022] exist Figure 1 to Figure 5 shows in detail generally the valve housing designated 1 in which the control piston 2 is arranged and designed to be axially displaceable. The control piston 2 is operatively connected to a spring 3 supported on a spring support 4 . The spring support 4 has a projection 5 which corresponds to the groove 6 on the inner wall of the valve housing 1 and thus ensures a firm hold in the valve housing 1 . The spring carrier 4 is made of an elastic material, in particular plastic, which is preferably produced according to the injection molding method. As a result, the spring support 4 can be moved and snapped into the central opening of the valve sleeve 1 , so that simple assembly is possible and a good fixation of the spring support 4 in the valve sleeve 1 is obtained.

[0023] according to figure 1 , in the opening 7 of the spring support 4 is fitted an axial filter 8 which prevents the penetration of dirt particles into the area of the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com