Detecting thermal events in battery packs

A technology for detectors and battery modules, which is applied to battery pack components, batteries, and measuring electricity, and can solve problems such as increasing battery pack size, cost, complexity, separation, and delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

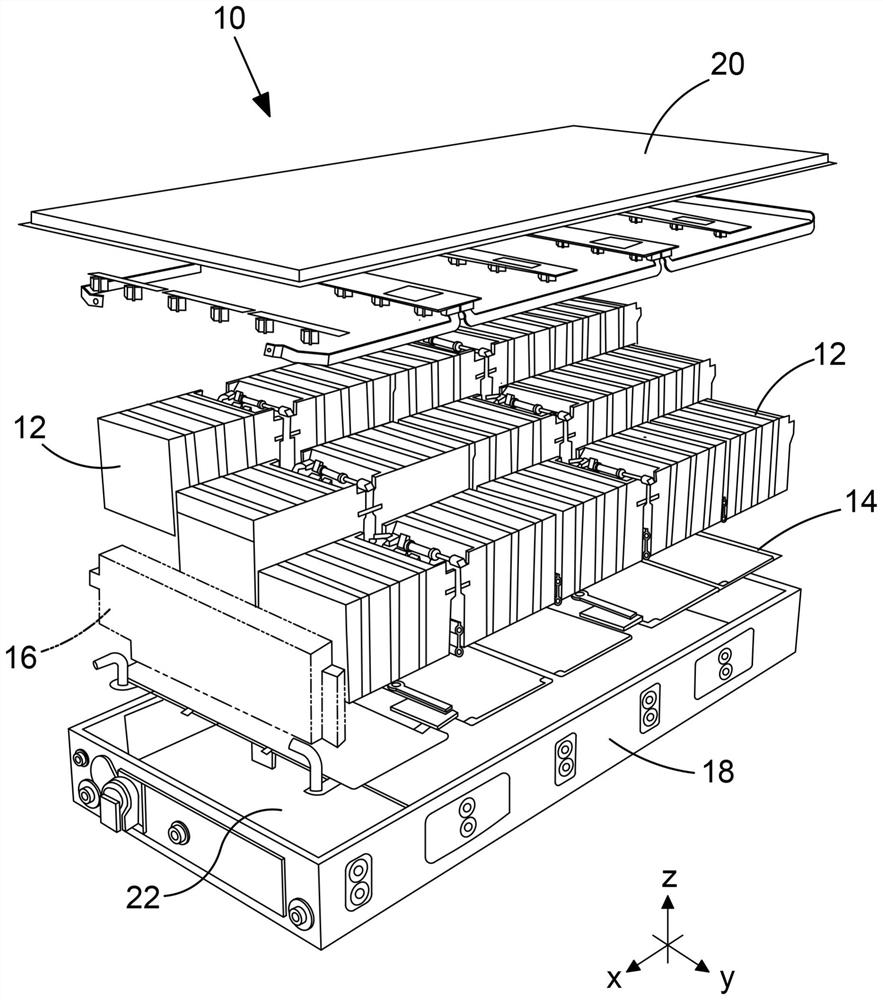

[0084] figure 1 An example of a battery pack is shown. figure 1 Our battery packs are designed for use with electric and hybrid vehicles, especially high horsepower applications such as buses, trucks, vans, construction equipment, etc.

[0085] refer to figure 1 , the battery pack 10 includes: a plurality of battery modules 12 , a plurality of cooling plates 14 , a battery management system 16 , a surrounding frame 18 , a top plate 20 and a bottom plate 22 . In this example, fifteen battery modules 12 are provided in five rows of three modules. Each row of three battery modules 12 is located on a corresponding cooling plate 14 . The cooling plate 14 is hollow to allow coolant flow. A battery management system 16 is located at one end of the battery pack. In the assembled state, a top plate 20 and a bottom plate 22 are attached to the top and bottom of the frame 20, respectively. Battery modules 12 , cooling plate 14 , and battery management system 16 are housed within fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com