Heat treatment carburizing process of carburizing steel

A carburizing steel and carburizing technology, which is applied in the field of heat treatment of metal materials, can solve problems such as the inability to meet the service performance requirements, and achieve the effects of avoiding carbide coarsening, increasing carbide size, and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

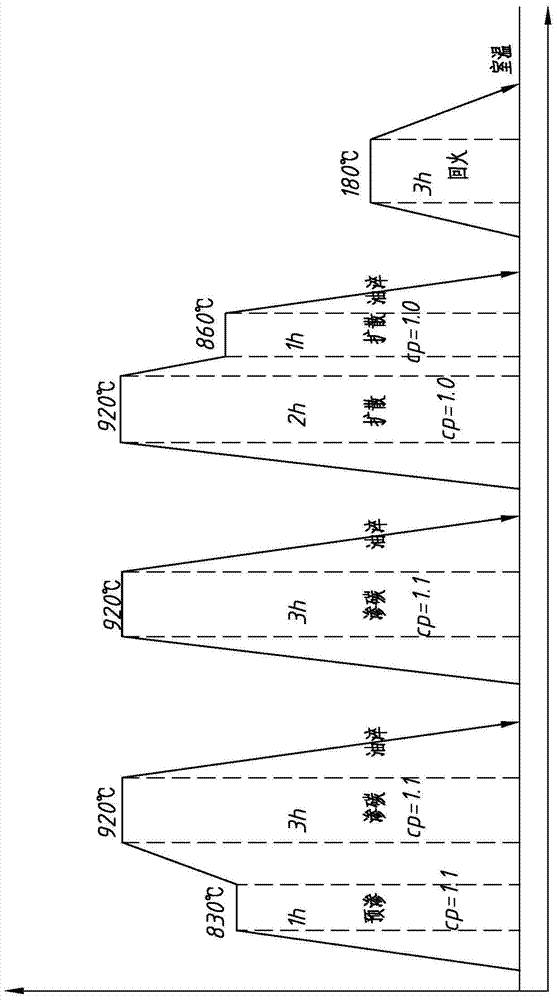

[0025] according to image 3 The process curve diagram proceeds:

[0026] (1) Pre-carburization: 1h pre-carburization at 830°C and carbon potential 1.1;

[0027] (2) Cyclic carburizing: use 920°C, carbon potential 1.1, carry out carburizing for 3 hours, and then cool in oil at 100°C; after that, use 920°C, carbon potential 1.1, carry out carburizing for 3 hours, and then in 100°C The process step of cooling in oil is cycled once to complete the cyclic carburizing with 2 cycles;

[0028] (3) Diffusion and quenching: Use 920°C, carbon potential 1.0, and carry out carburizing diffusion for 2 hours to obtain a gentle carbon concentration distribution and reduce the stress caused by carburizing heat treatment; after diffusion, cool the temperature to 860°C, carbon potential 1.0, after holding for 1 hour, quench and cool in oil at 100°C;

[0029] (4) Tempering: Tempering at 180°C for 3 hours.

[0030] After completion, use the peeling method to detect the carbide content on the ...

Embodiment 2

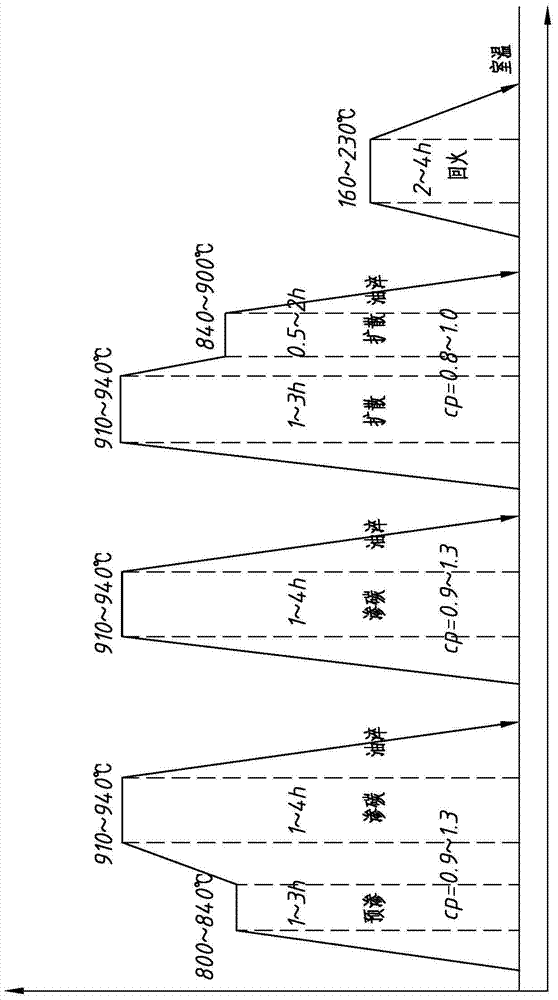

[0032] according to Figure 4 The process curve diagram proceeds:

[0033] (1) Pre-carburization: 800°C, carbon potential 0.9, 2h pre-carburization;

[0034] (2) Cyclic carburizing: use 910°C, carbon potential 0.9, carry out carburizing for 1h, and then cool in oil at 50°C; after that, use 910°C, carbon potential 0.9, carry out carburizing for 1h, and then in 50°C The process step of cooling in oil is cycled once to complete the cyclic carburizing with 2 cycles;

[0035] (3) Diffusion and quenching: use 910°C, carbon potential 1.0, and carry out carburizing diffusion for 2 hours to obtain a gentle carbon concentration distribution and reduce stress caused by carburizing heat treatment; after diffusion, cool the temperature to 860°C, carbon potential 1.0, after holding for 1 hour, quench and cool in oil at 100°C;

[0036] (4) Tempering: Tempering at 180°C for 3 hours.

[0037] After completion, use the peeling method to detect the carbide content on the surface: the carbide...

Embodiment 3

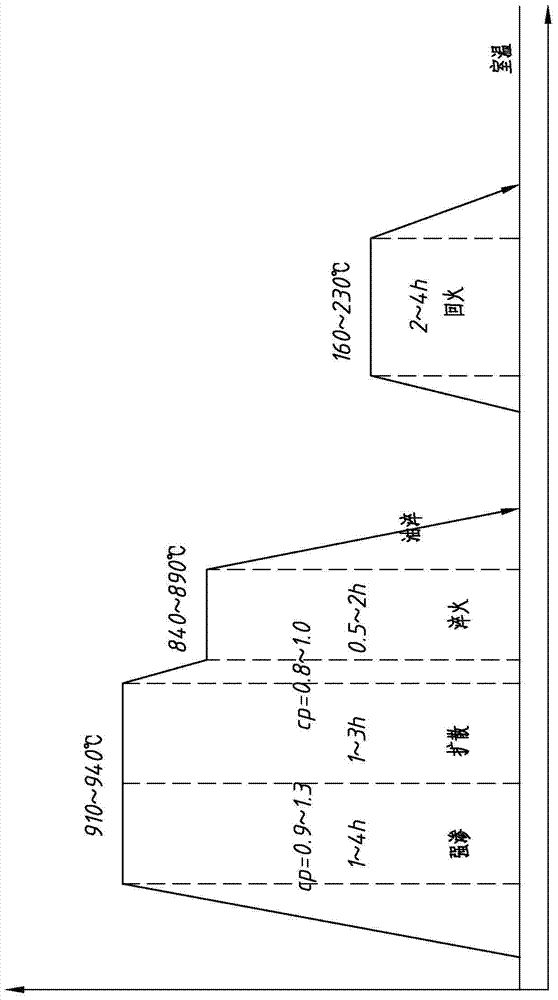

[0039] according to Figure 5 The process curve diagram proceeds:

[0040] (1) Pre-carburization: 840°C, carbon potential 1.3, 3h pre-carburization;

[0041] (2) Cyclic carburizing: use 940°C, carbon potential 1.3, carry out carburizing for 4 hours, and then cool in oil at 130°C; after that, use 940°C, carbon potential 1.3, carry out carburizing for 4 hours, and then in 130°C The process step of cooling in oil is cycled once to complete the cyclic carburizing with 2 cycles;

[0042] (3) Diffusion and quenching: use 940°C, carbon potential 1.0, and carry out carburizing diffusion for 2 hours to obtain a gentle carbon concentration distribution and reduce stress caused by carburizing heat treatment; after diffusion, cool the temperature to 900°C, carbon potential 0.8, after holding for 1 hour, quench and cool in oil at 100°C;

[0043] (4) Tempering: Tempering at 180°C for 3 hours.

[0044] After completion, use the peeling method to detect the carbide content on the surface:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com