A roll material surface cleaning machine

A cleaning machine and cleaning mechanism technology, applied in the direction of electrostatic cleaning, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of complex installation, difficult maintenance, low dust removal rate, etc., to achieve high dust removal efficiency, Easy to install and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

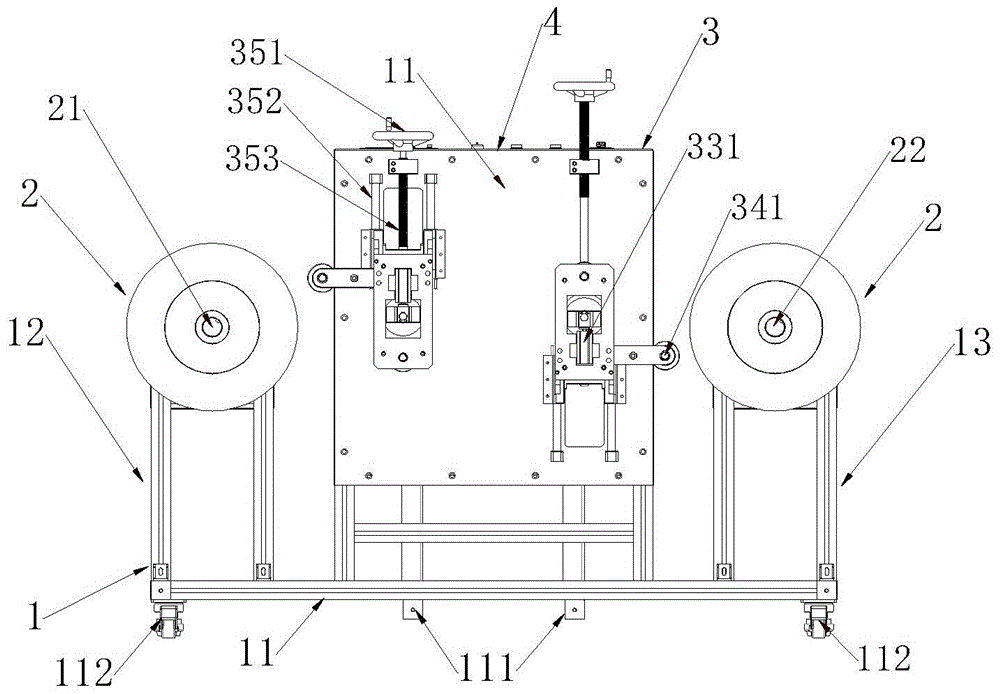

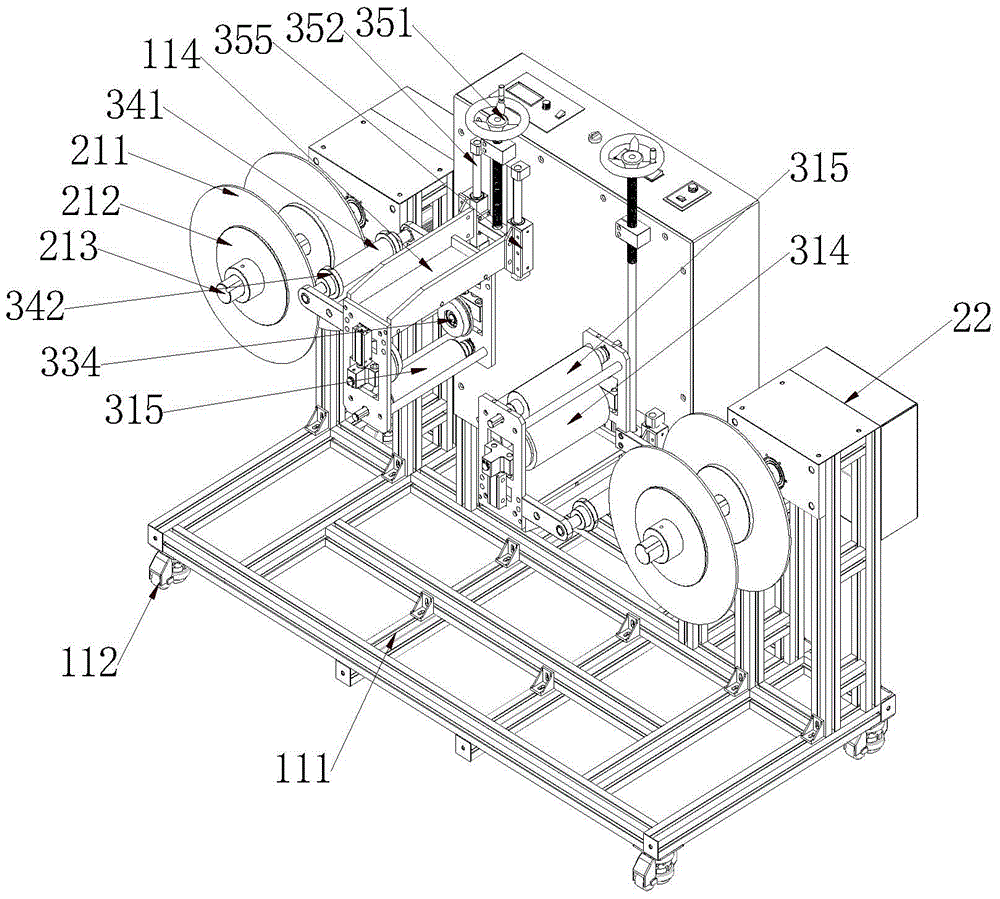

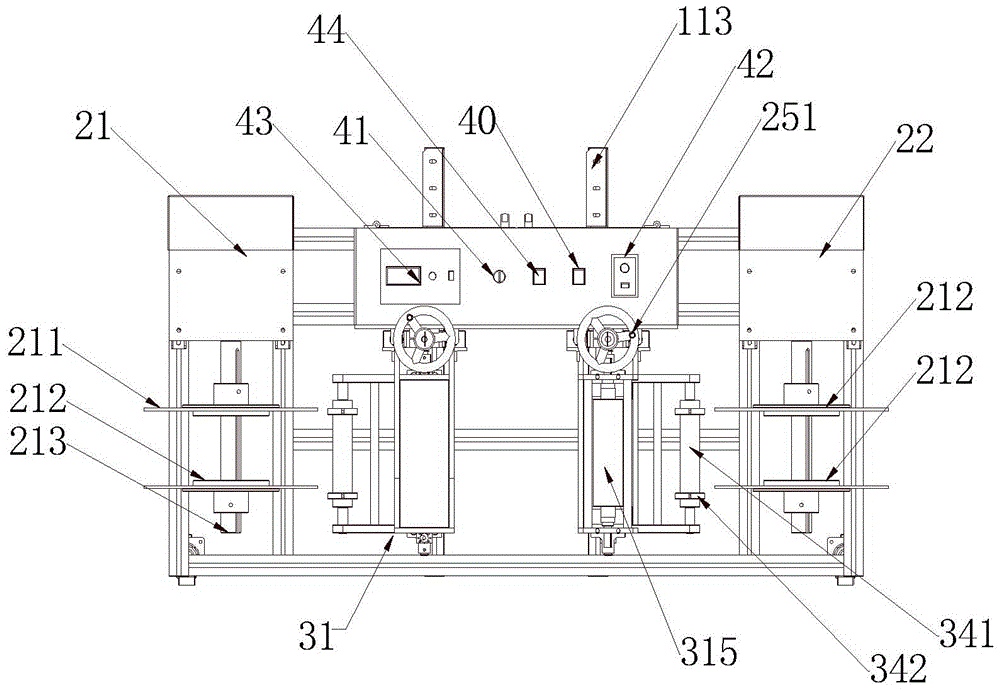

[0030] like Figure 1 to Figure 3 As shown, a roll-shaped material surface cleaning machine provided by the present invention includes a body structure 1, a feeding and unwinding structure 2, a cleaning mechanism 3 and an operation console 4. The body structure 1 includes a base 11 and Receiving end support 12 and discharging end support 13, described receiving end support 12 and discharging end support 13 are respectively used for supporting and fixing the receiving structure 21 and the discharging structure 22 of described receiving and discharging structure, described cleaning Mechanism 3 is arranged between described receiving structure 21 and discharging structure 22, as figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com