Multifunctional injection molding machine

An injection molding machine, multi-functional technology, applied in the field of multi-functional injection molding machines, can solve the problems of not reaching the theoretical height, troublesome injection molding production users, strength and quality not as good as ideal, etc., to achieve simple structure and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

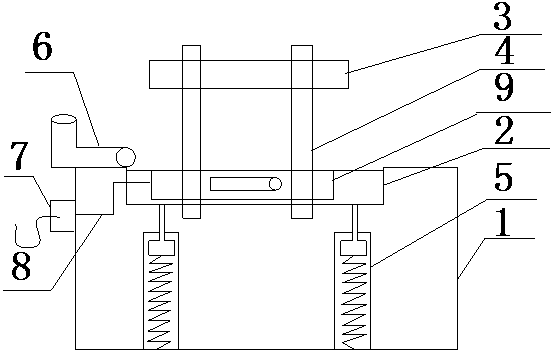

[0009] Such as figure 1 A multifunctional injection molding machine shown includes an injection molding machine main body 1, a lower cover plate 2, an upper cover plate 3, a display instrument 7 and a data line 8, and a pressure pump 5 is fixed inside the main body 1 of the injection molding machine. The top of the pressure pump 5 is fixed with a lower cover plate 2, the upper cover plate 3 and the lower cover plate 2 are connected by a fixed rod 4, the left end of the lower cover plate 2 is fixed with a feed inlet 6, and the main body of the injection molding machine 1 A display instrument 7 is provided on the left side of the front panel, and a temperature detection device 9 is fixed on the lower cover plate 2, and the temperature detection device 9 is connected to the display instrument 7 through a data line 8. The invention has the beneficial effects of simple structure and low manufacturing cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com