Injection molding machine

A technology of injection molding machine and main body, which is applied in the field of injection molding machines, can solve the problems of not reaching the theoretical height, troublesome injection molding production users, strength and quality not as good as ideal, etc., and achieve the effect of simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

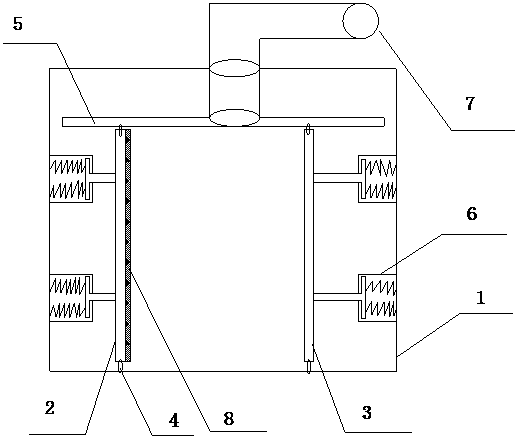

[0009] Such as figure 1 A kind of injection molding machine shown, comprises injection molding machine main body 1, left baffle plate 2, right baffle plate 3 and sliding ring 4, and described injection molding machine main body 1 is provided with beam 5, and described left baffle plate 2 and right baffle plate The top of 3 is connected with beam 5 through sliding ring 4, the bottom of said left baffle 2 and right baffle 3 is connected with the bottom of injection molding machine main body 1 through sliding ring 4, and said left baffle 2 is connected with injection molding machine main body 1 The left side of the injection molding machine body 1 is connected with the right side of the injection molding machine body 1 through the pressure pump 6. The top of the injection molding machine body 1 is fixed with a feed port 7. The left baffle plate 2 The right side of the surface is coated with a layer of anti-sticking material 8. The invention has the beneficial effects of simple s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap