Pressing device for fan motor stator

A fan motor and stator technology, applied in the manufacture of stator/rotor bodies, presses, stamping machines, etc., can solve the problems of pressing on employees, low efficiency of manual pressing operations, and difficulty in industrialized production, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

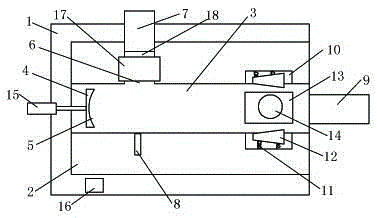

[0010] Combine below figure 1 Specific description embodiment:

[0011] Such as figure 1 As shown, the pressing device of the fan motor stator, the pressing device of the fan motor stator includes a frame 1, the frame 1 is provided with a workbench 2, and a long workbench is provided in the middle of the workbench 2 Groove 3, the front end and rear end opening of working groove 3, the front end opening of described working groove 3 is provided with push block 4, and the front end of described push block 4 is arc-shaped curved surface 5, and the arc-shaped curved surface 5 The radian is consistent with the radian of the outer surface of the fan motor stator. The rear end of the push block 4 is connected with a cylinder 15, and the push block 4 can slide in the working groove 3 under the action of the cylinder 15; The front end of the side near the working tank 3 is provided with a feeding port 6, and the feeding port 6 is connected with a feeding chute 7, and the other side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com