Folding machine with straight knife type folding mechanism

A technology of folding mechanism and folding machine, which is applied in the direction of folding thin materials, thin material processing, transportation and packaging, etc. It can solve the problems of not very high requirements for folding effect, restricting the development of enterprises, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

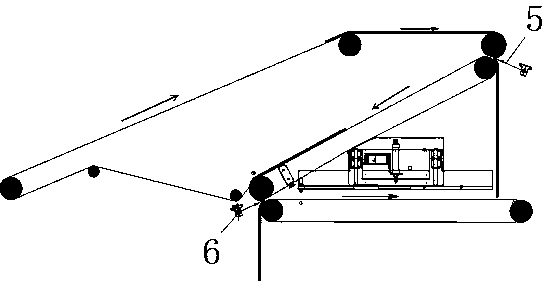

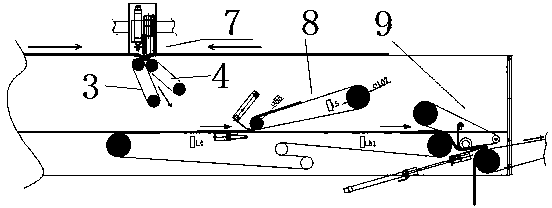

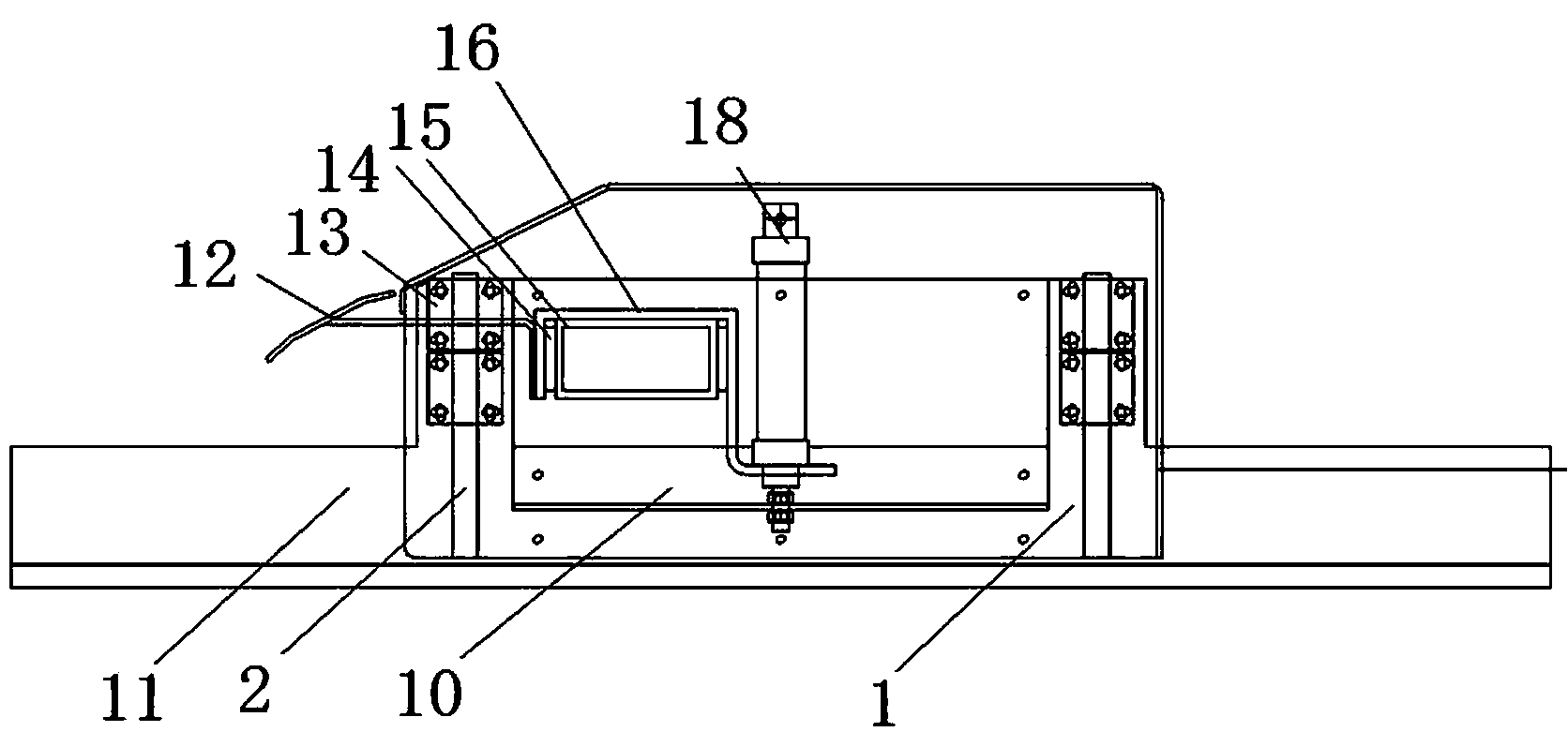

[0015] The reference numerals in the accompanying drawings are as follows: 1. Gate knife, 2. Guide rail, 3. The first transmission roller, 4. The second transmission roller, 5. The first folding device, 6. The second folding device, 7. The third folding device, 8. The fourth Folding device, 9 fifth folding device, 10 knife plate reinforcement block, 11 knife cover box side plate, 12 cover plate support assembly, 13 slider, 14 tapping spacer, 15 cylinder beam, 16 knife cover box seal Plate, 17 cylinder holders, 18 cylinders.

[0016] The folding machine mainly described in the present invention is equipped with a straight-knife folding mechanism, which mainly includes a frame and five folding devices arranged on the frame. The difference between it and the prior art is that the five folding devices The third folding device is arranged on the platform of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com