Magnesium metal smelting reduction slag conveying system

A conveying system and metal magnesium technology, applied in the field of metallurgical technology, can solve problems such as burns to on-site operators and affect the time of reducing slag to be released from the furnace, so as to achieve the effects of shortening the time of furnace release and system safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

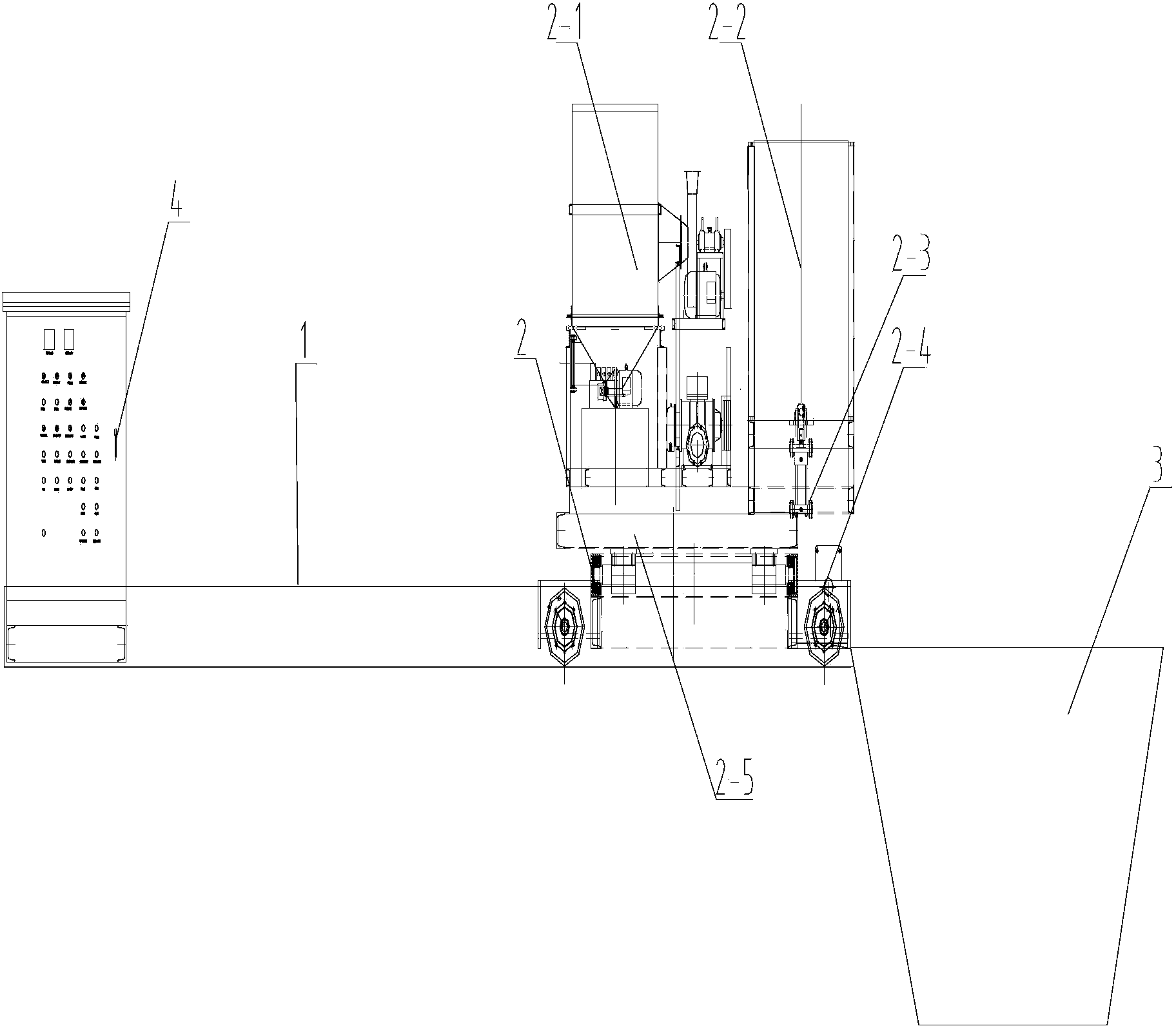

[0012] Example 1 Composition of a metal magnesium smelting reduced slag delivery system and the functions of its components:

[0013] The system consists of a circular track 1, an electric slag tank trolley 2, a reducing slag storage tank 3, and an electrical control system 4. It is characterized in that the electric slag tank trolley 2 of the metal magnesium smelting reducing slag conveying system runs on the circular track 1, The system runs under the control of the electrical automatic control system 4 . The electric slag tank trolley 2 is composed of a dust collector 2-1, a slag tank 2-2, a slag tank dumping device 2-3, a drive motor 2-4, and an electric slag tank trolley body 2-5. The electrical control system 4 has on-site panel operation and fully automatic control functions.

Embodiment 2

[0014] Embodiment 2 A working process of a metal magnesium smelting reducing slag conveying system:

[0015] After the high-temperature reduction slag of the reduction furnace falls into the slag box 2-2 on the electric slag tank trolley 2, the on-site operators can control the operation of the trolley through panel operation or remote control, and reach the position where the reduction slag storage tank 3 can be unloaded and dumped. Finally, the high-temperature reducing slag in the slag box 2-2 is poured into the reducing slag storage tank 3 by the action control of the slag box dumping device 2-3, and then the slag box 2-2 is reset, and the electric slag tank trolley 2 returns to the original position. The initial position to complete the reduction slag conveying process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com