Pulse timing and counting device and method for liquid flow verification

A technology of pulse timing counting and liquid flow, applied in liquid/fluid solid measurement, measurement device, frequency measurement device, etc., can solve problems such as difficulty in ensuring synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

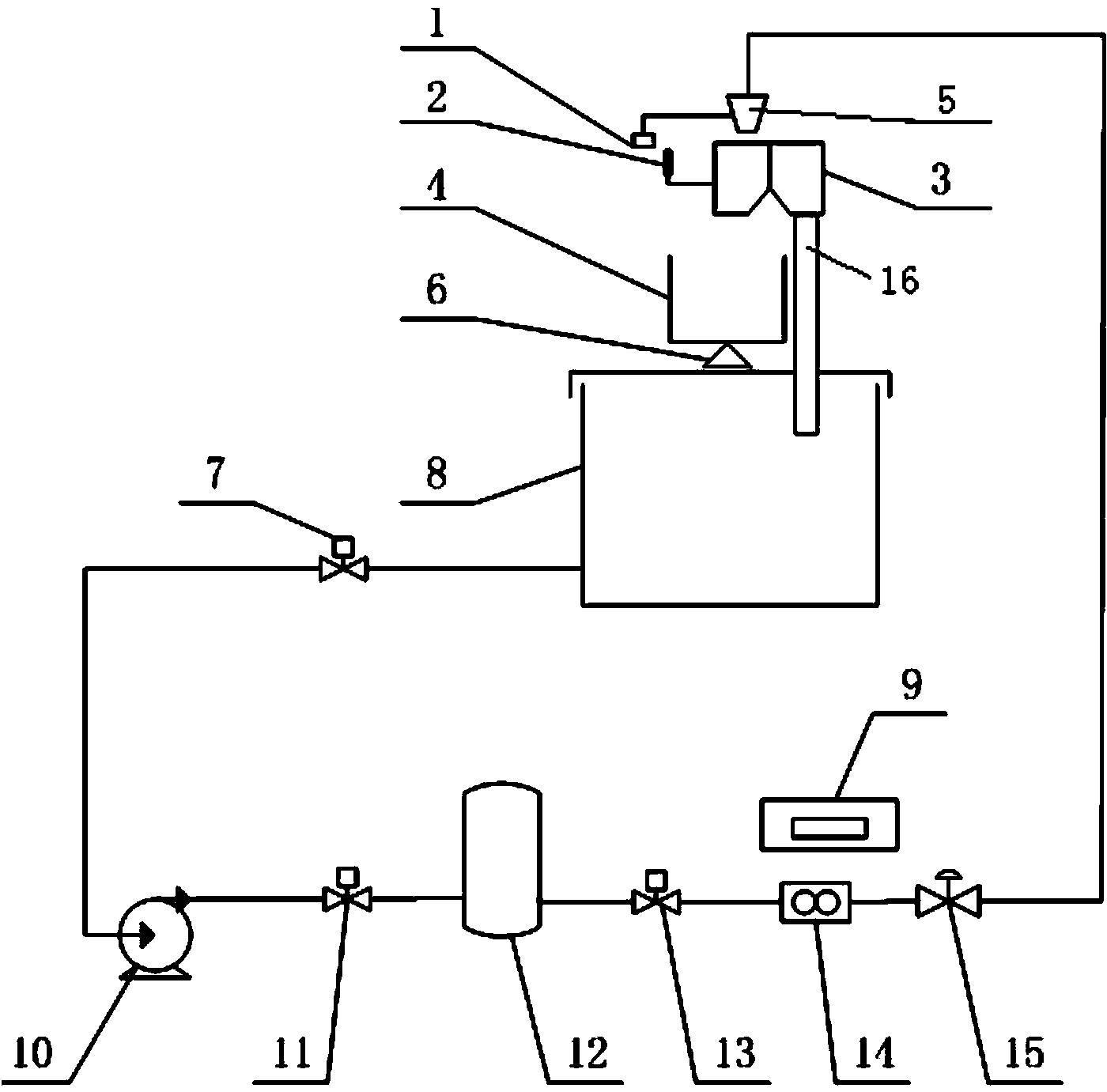

[0022] A pulse timing counting device for liquid flow verification according to the present invention, which is used in a liquid flow device, and a pulse timing counting device 9 is provided above the flow meter 14 of the liquid flow device;

[0023] Such as figure 1 As shown, the liquid flow device includes a circulating water tank 8, which is connected to a water pump 10 through a pipeline; the water pump 10 is connected to a surge tank 12 through a pipeline, and the surge tank 12 is connected to a flow meter 14 and a flow meter 14 through a pipeline. Connect the water outlet pipe 5 set above the commutator 2 through a pipeline; an electronic scale 6 is set above the circulating water tank 8, and a weighing water tank 4 is placed on the electronic scale 6, and next to the weighing water tank 4 is the circulating water tank inlet 16; the commutator 3 is set above the entrance of the weighing water tank 4 and the circulating water tank, the outlet pipe 5 is set above the commutato...

Embodiment 2

[0027] Using the pulse timing counting method of the pulse timing counting device for liquid flow verification described in Example 1, the steps are as follows:

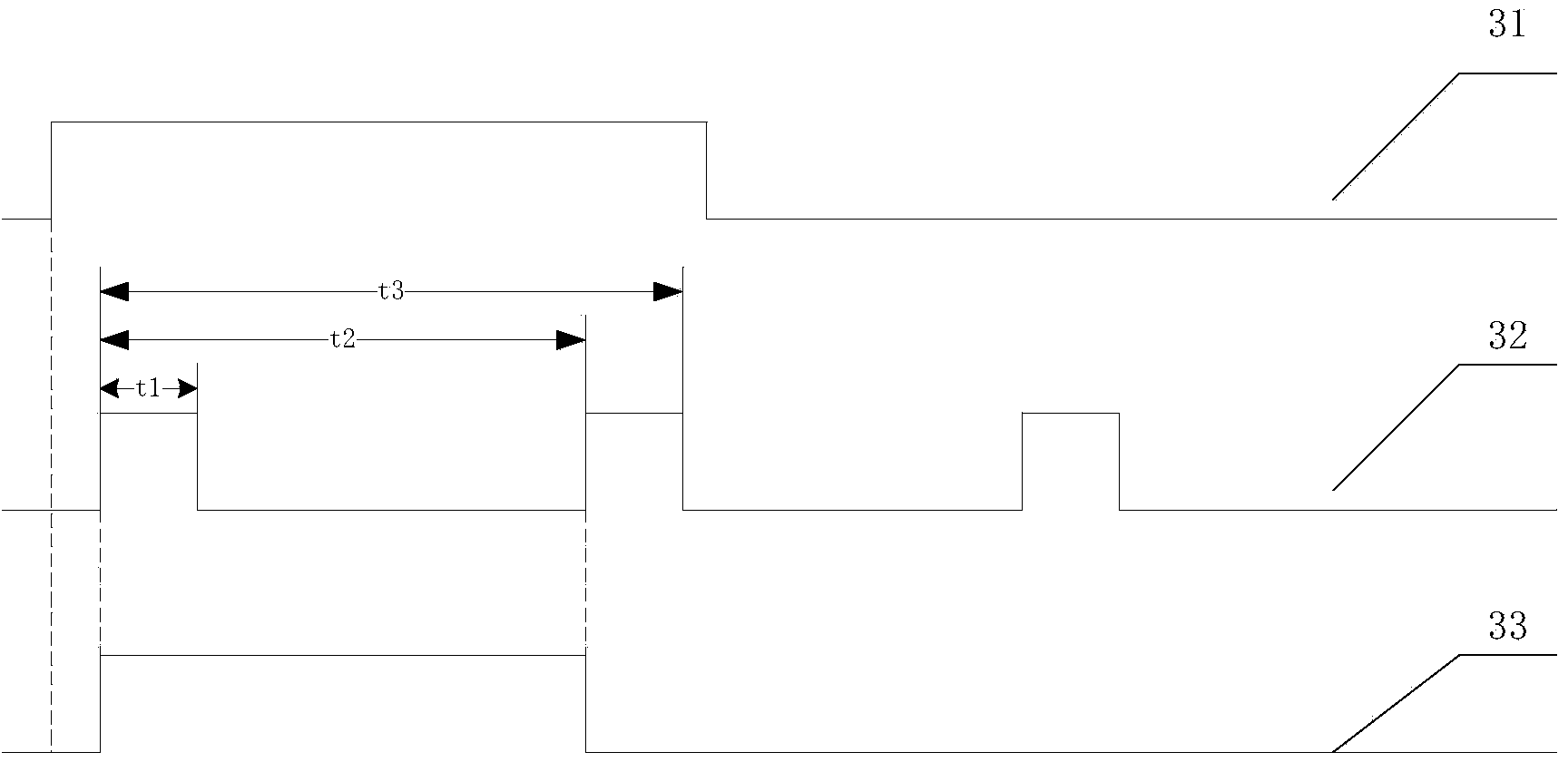

[0028] First, fill the circulating water tank 8 with more than 80% water. After the weighing tank 4 is empty, the water is peeled. The commutator 5 makes the water flow to the circulating water tank 8. Open the pump inlet valve 7, the pump outlet valve 11, and the flow meter inlet valve 13 respectively. , After adjusting the flow through the water pump 10 and the regulating valve 15 to reach the verification value, the commutator 3 reverses to make the water flow into the weighing tank 4, and the shutter 1 on the commutator 3 blocks the photoelectric switch 2 to generate a trigger signal. The trigger signal is transmitted to the pulse timing and counting device 9 to start timing and counting. When the water in the weighing tank 4 reaches the predetermined quality, the commutator 3 reverses to stop timing and counting, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com