A test method and test device for scale breaking test of strip steel

The technology of a test device and test method is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., which can solve the problems of lack of special test equipment for scale breaking process, achieve simple structure, reliable operation, and improve pickling speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings.

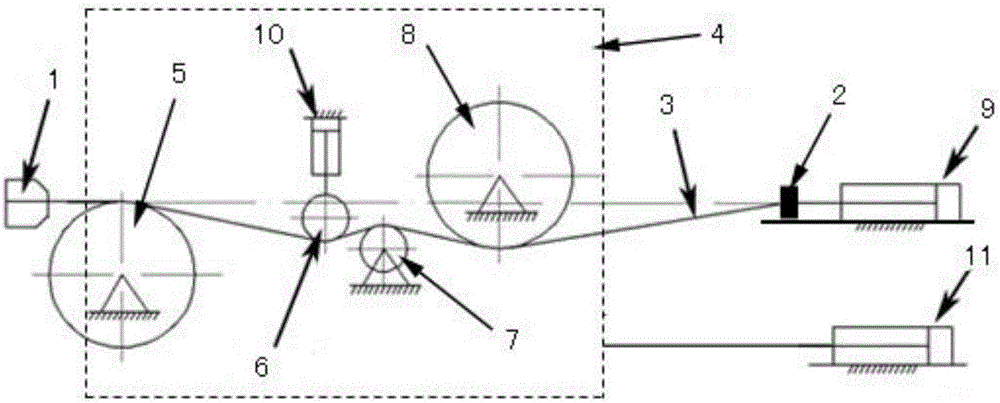

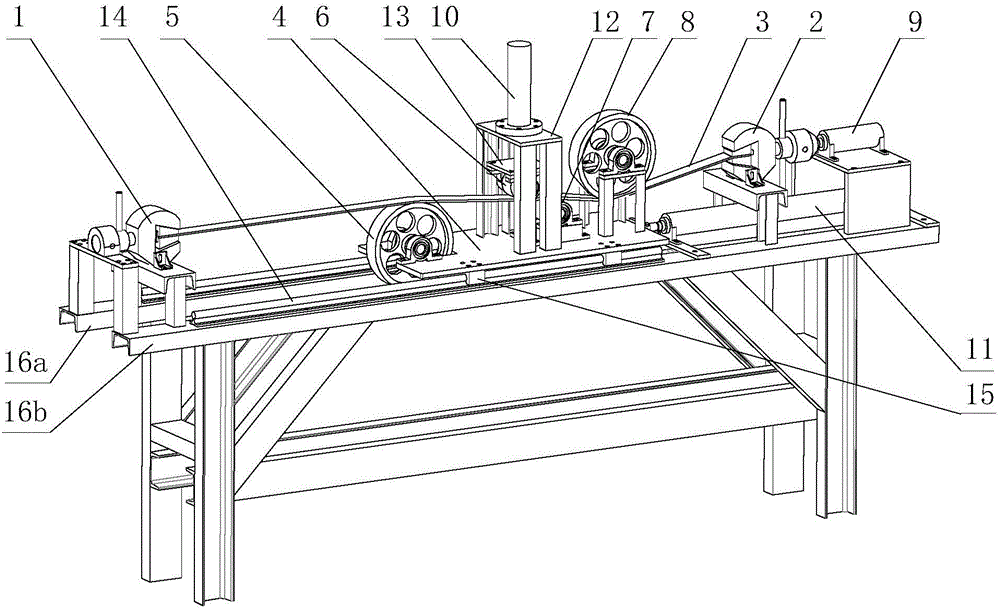

[0055] figure 1 Among them, the tensile leveling scale breaking test device is based on the common tension leveling scale breaking machine in the acid rolling mill of the iron and steel production enterprise, and is designed according to its working principle and the principle of "easy to test". In order to achieve the expected scale-breaking effect, the key parts of the test device (mainly referring to the size of the parts of each roller), the material and the relevant installation positions are consistent with the actual production equipment, and the tension control method and the pulling and straightening movement method has been redesigned.

[0056] The test principle of this test device is that a fixed first strip clamp 1 is set at one end of the test frame (not shown), and a second strip steel movable along the frame is set at the other end of the test frame. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com