Numerical analysis method applied to leaking and channeling mechanism and prevention and control method of injection fluid

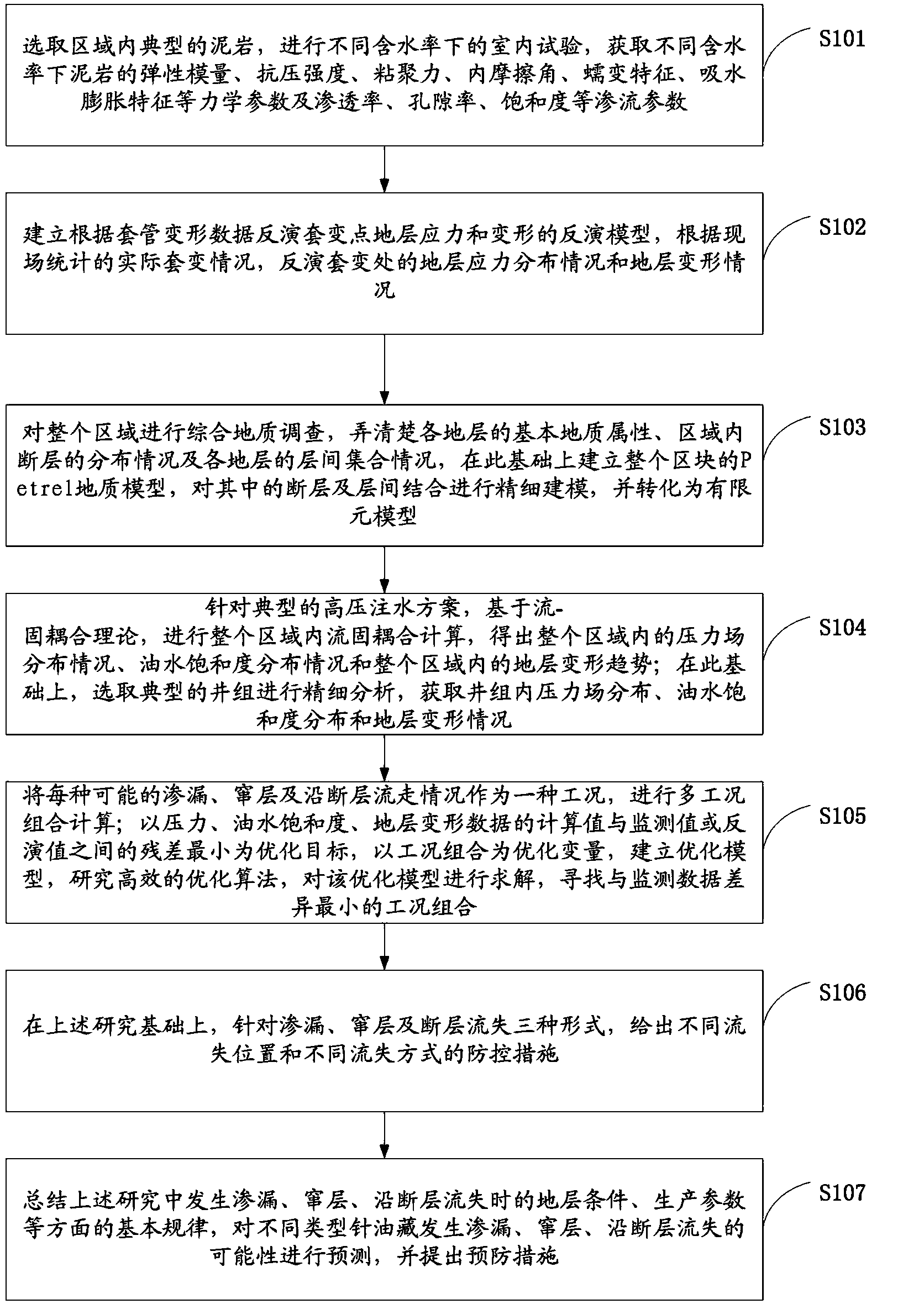

A numerical analysis and mechanism technology, which can be used in material inspection products, soil material testing, etc., to solve problems such as mudstone water absorption and research gaps in mudstone layer leakage and channeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] All experiments in the embodiments of the present invention are carried out in the State Key Laboratory of Oil and Gas Reservoir Geology and Development Engineering (Southwest Petroleum University), and the instruments and equipment used include: rock triaxial testing machine, rock rheological testing machine, high temperature and high pressure rock multi-parameter Measuring instrument, etc.

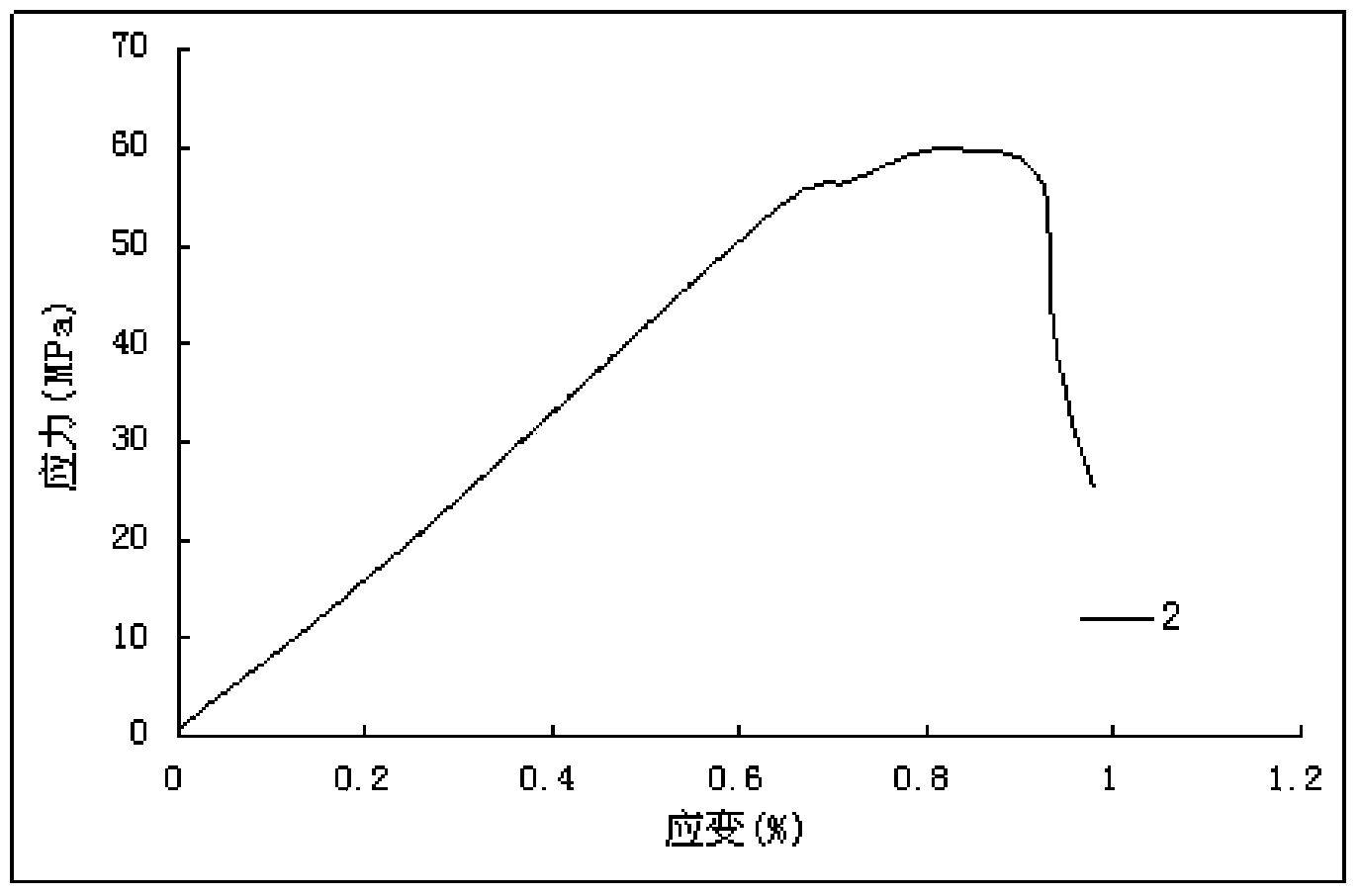

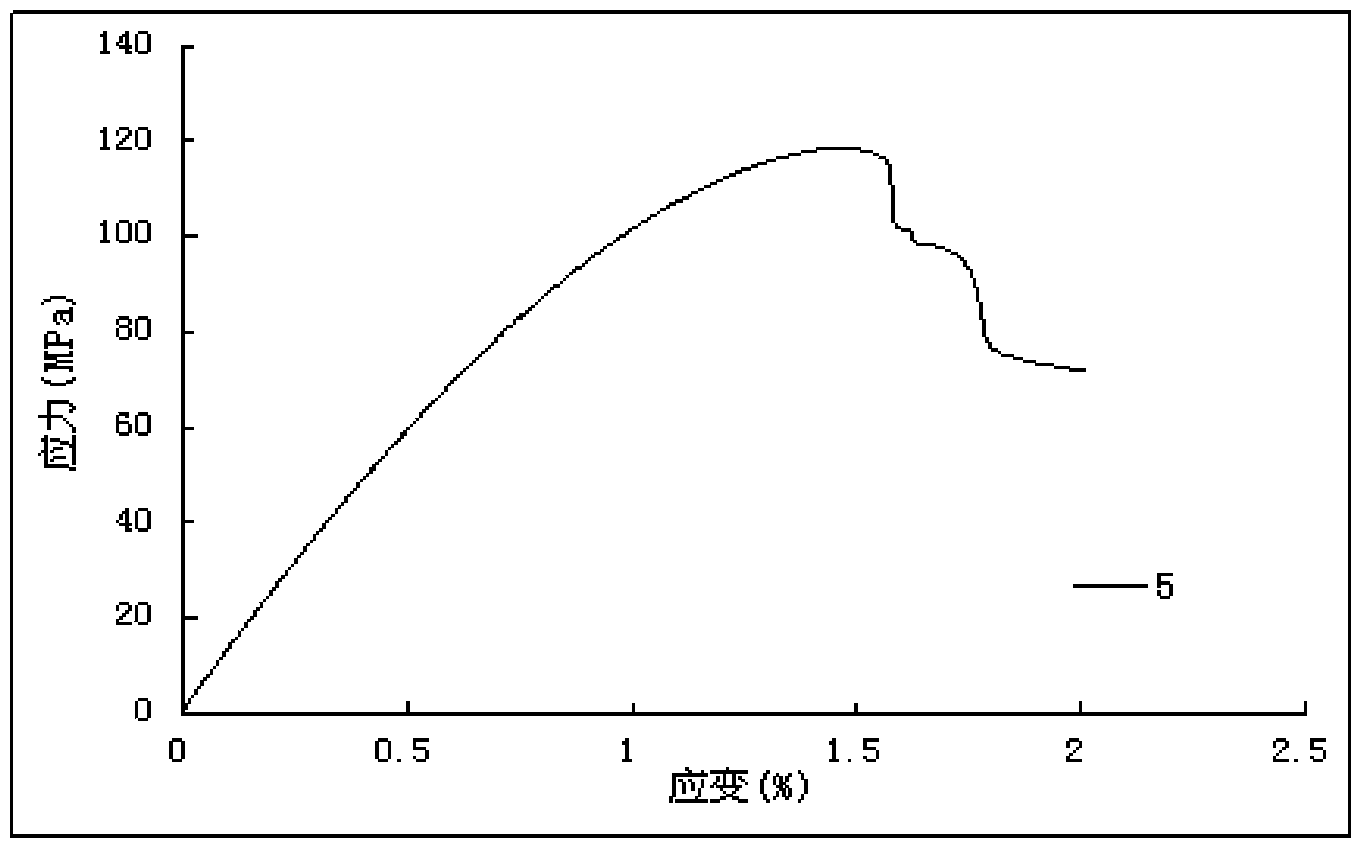

[0084] There are two batches of rock cores used in the embodiments of the present invention. The first batch of cores comes from 11 mudstone and argillaceous sandstone cores of Mao 11 and Mao 111 in Toutai Oilfield, all of which are standard cores; 10 mudstone and sandstone cores come from Well Sheng 38-1 and Well Shu 14 in Yushulin Oilfield . Among the 11 cores from Toutai Oilfield in the first sample, four cores were used to test the stress sensitivity, namely 1#, 3#, 4# and 10# cores, and the rest 2#, 5#, 6#, 7#, 8#, 9#, 11# cores are used to test the mechanical parameters of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com