Light guide plate and backlight module using light guide plate

A technology of backlight module and light guide plate, applied in the field of light guide plate, can solve the problems of inability to meet the conditions of total reflection, increase the divergence angle of light, escape, etc., and achieve the effect of reducing side lighting phenomenon, increasing divergence angle and uniform transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced. The direction terms mentioned in the present invention, such as "up", "down", "front", "rear", "left", "right", etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate, not to limit, the invention.

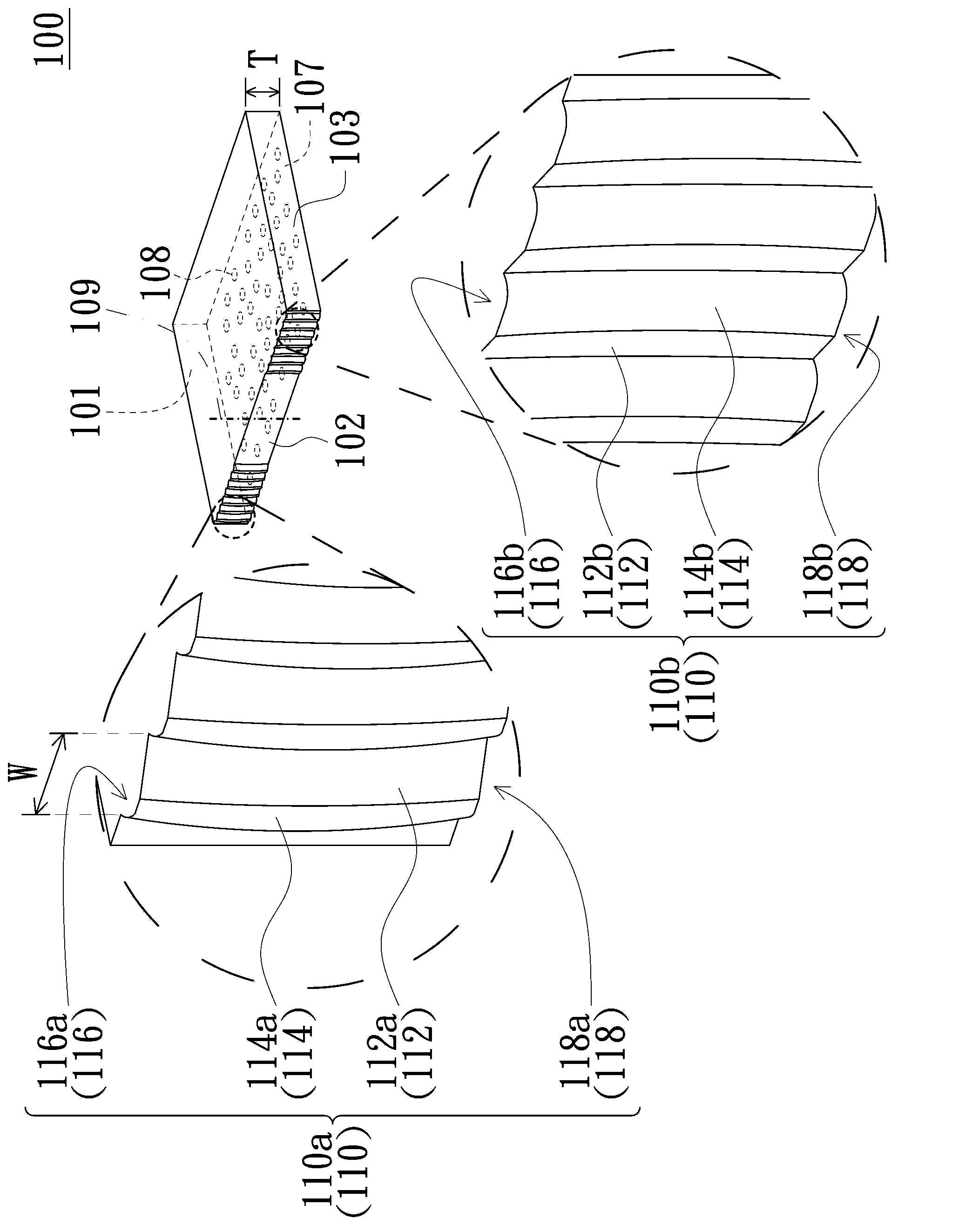

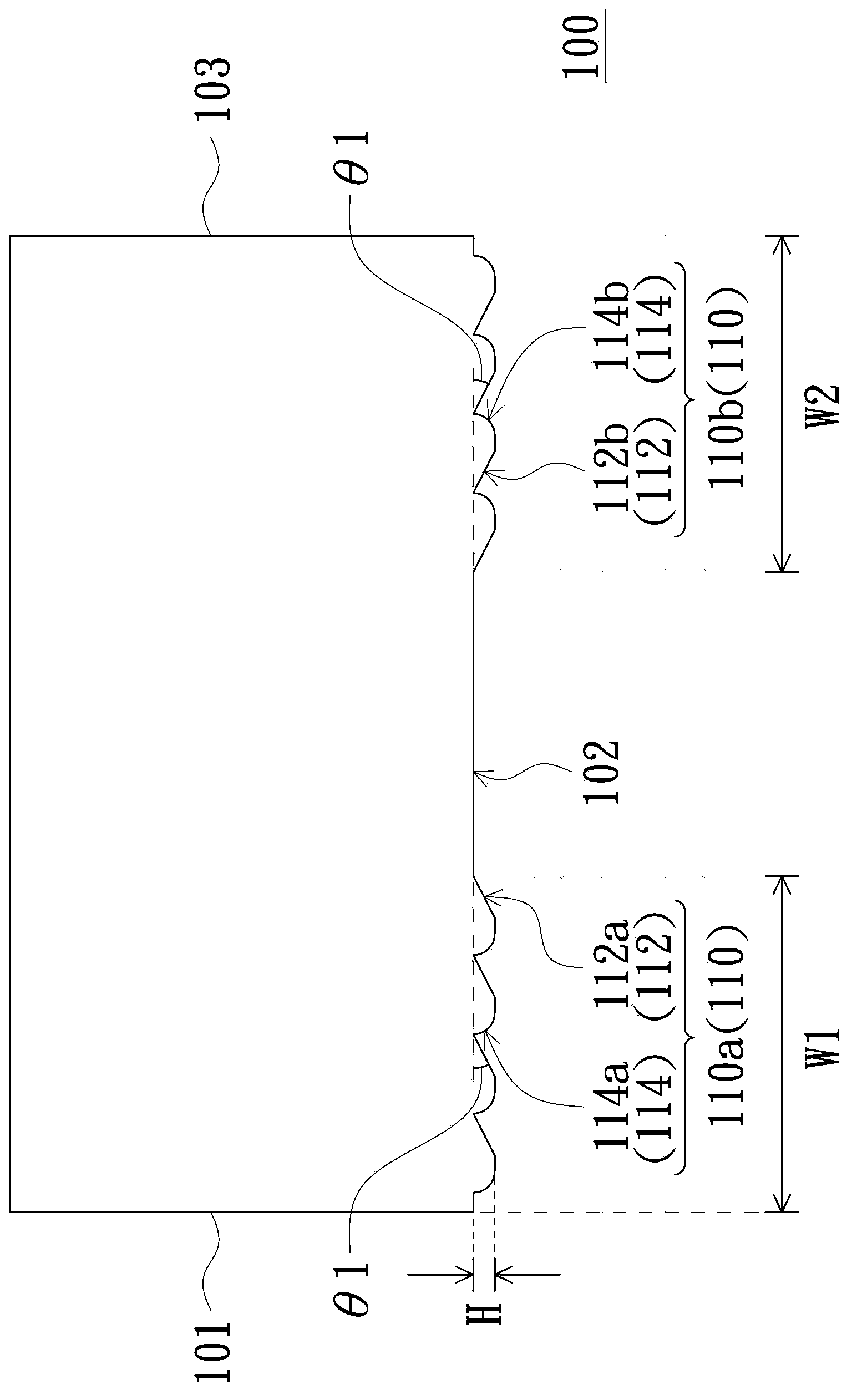

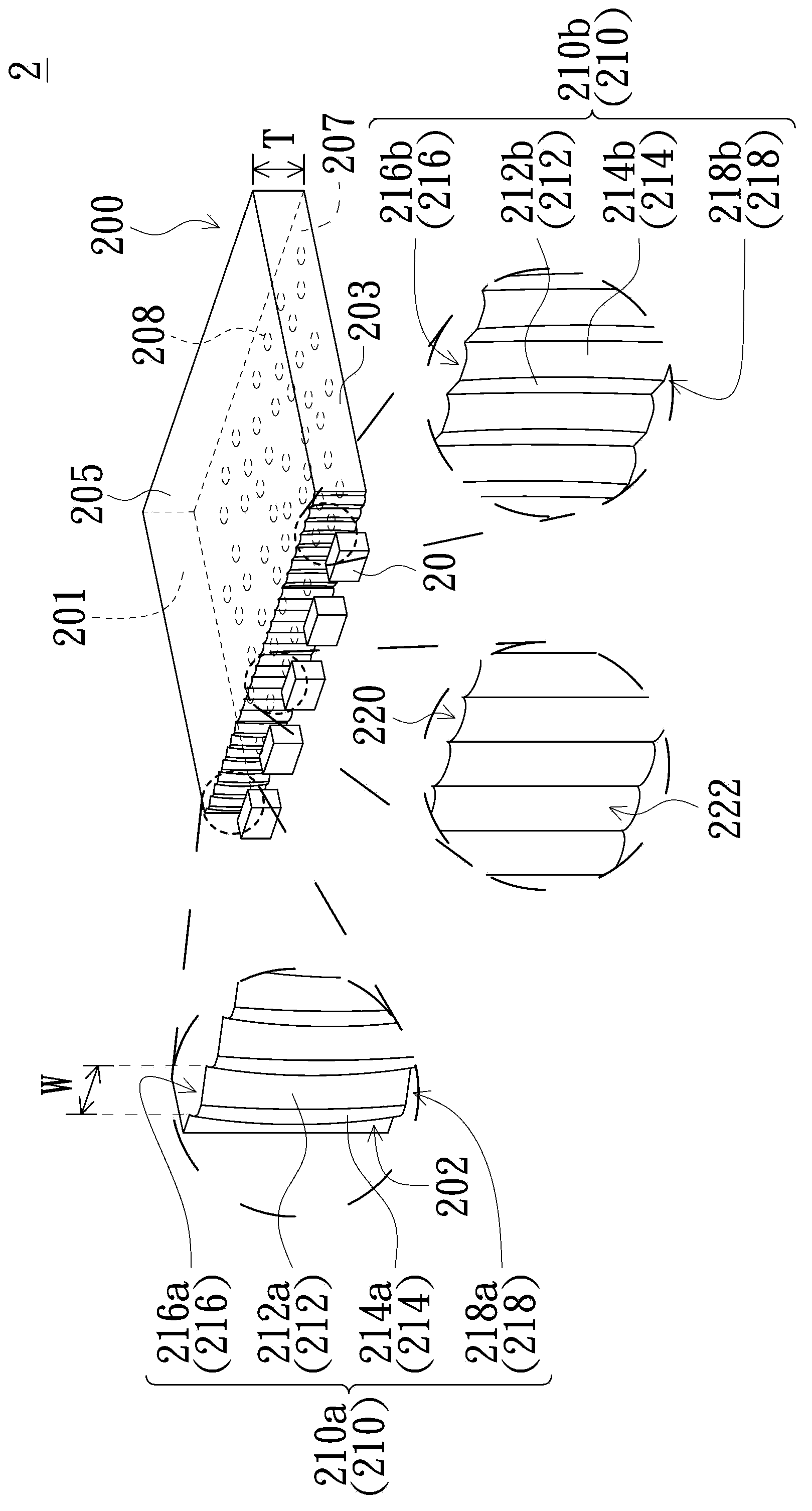

[0038] Figure 1A is a three-dimensional schematic diagram of a light guide plate in an embodiment of the present invention, Figure 1B then Figure 1A A top view of the light guide plate. Please also refer to Figure 1A and Figure 1B The light guide plate 100 has a light incident surface 102 , a first side surface 101 , a second side surface 103 , a light exit surface 105 and a bottom surface 107 opposite to the light exit surface. The light incident surface 102 has a plurality of strip optical microstructures 110, each strip optical microstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com