A white light LED device with uniform light emitting color temperature in a spatial solid angle and a packaging method thereof

A LED device, three-dimensional technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of increasing the complexity and incompatibility of the packaging process, and achieve the effect of improving the extraction ability, expanding the divergence angle, and improving the reflection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

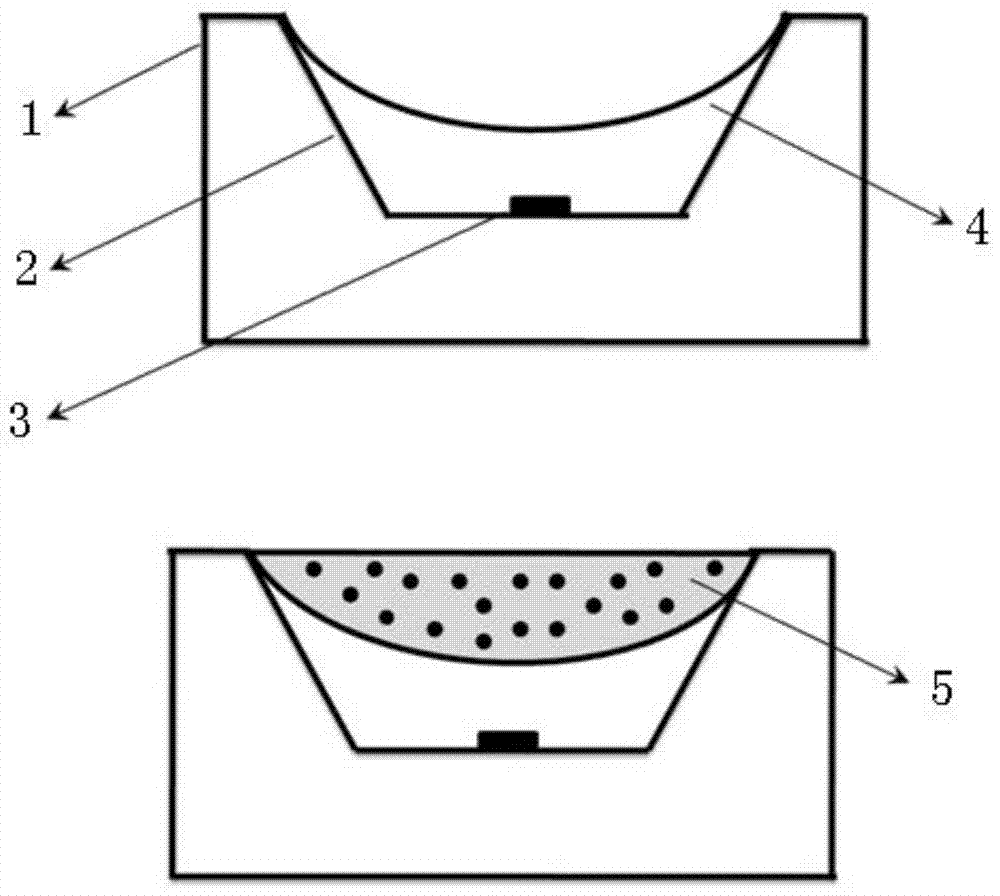

Method used

Image

Examples

Embodiment ( 1

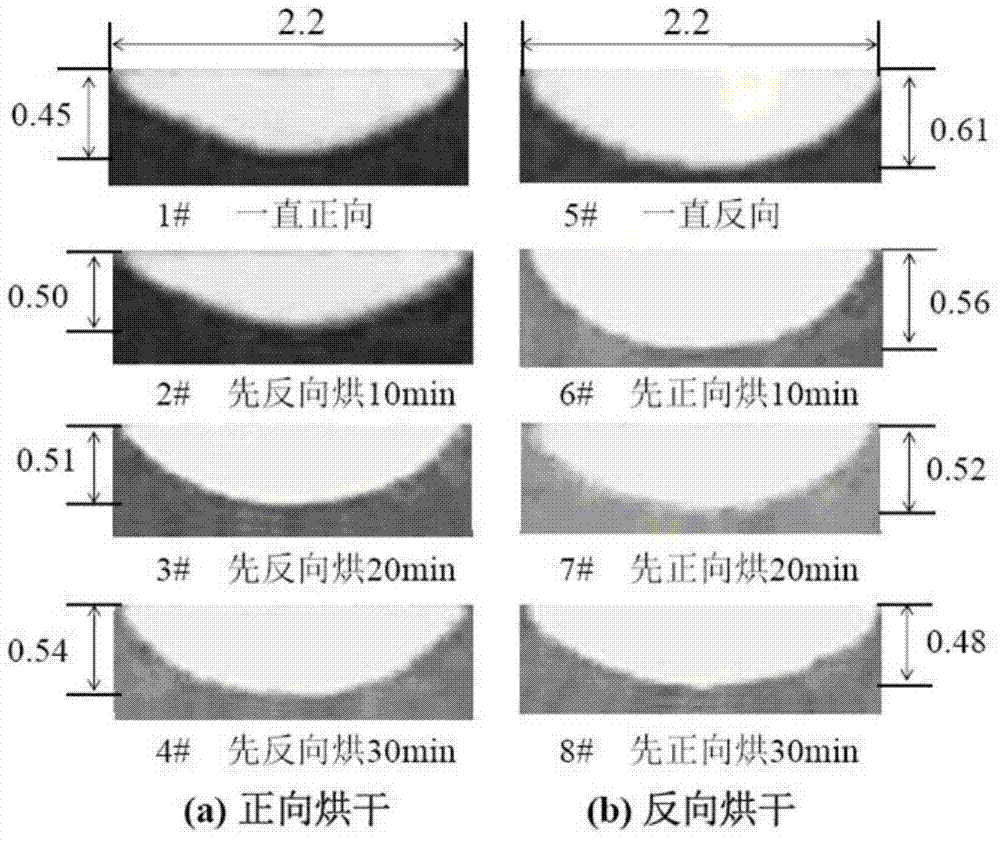

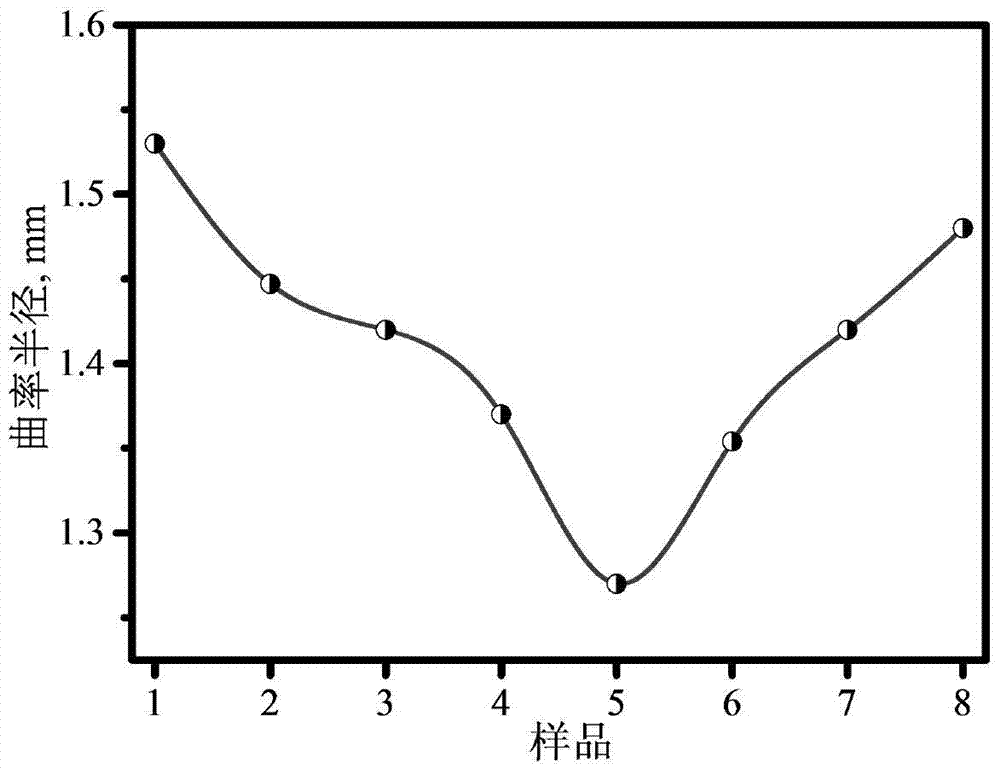

[0047] In this embodiment, a total of 9 groups of samples are designed, of which groups 1 to 8 are LED devices with a double-layer structure, and group 9 is a reference sample with a single-layer structure. First, mix A and B silica gel according to the ratio of 1:1, stir evenly, vacuum defoam and put it into the syringe. Set the air pressure of the dispenser to 330Kpa and the time to 0.1s. For 1 to 8 groups of samples, drop 3 drops of silica gel on the top of the LED blue light chip, and then move the LED bracket attached to the silica gel into a 150°C vacuum drying oven. Set the baking time to 2 hours. Among them, the first sample has been dried upright; the second group of samples was firstly dried in the reverse direction for 10 minutes, and then forwardly dried; the third group of samples was first reversely dried for 20 minutes, and then forwardly dried; the fourth group of samples First dry in the reverse direction for 30 minutes, and then dry in the forward direction;...

Embodiment ( 2

[0060] For samples 1# to 8#, replace the upper layer of phenyl high-refractive index silica gel with methyl low-refractive index silica gel to construct a gradient refractive index, and use the same method as Example (1) to package white LED devices; 9# sample is the upper layer and the lower layer Both are methyl low-refractive-index silica gels, and are packaged with white light LED devices in the same way as in Example (1). Figure 9-10 A comparison of the luminous intensity of a white LED device with a double-layer structure with a gradient refractive index structure packaged by the present invention as a function of current and a white LED device with a uniform refractive index structure is given. Such as Figure 9 For groups 1 to 4 of samples that were reverse-dried for 0, 10, 20 and 30 minutes and then forward-dried, the luminous intensity is almost higher than that of the 9# sample with a single refractive index, and the greater the current, the greater the effect mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com