Crossmember having integrated drive for conveying objects

A technology of horizontal brackets and driving components, which can be used in the direction of conveyor objects, motor vehicles, devices for coating liquid on surfaces, etc., and can solve problems such as impaired functions and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

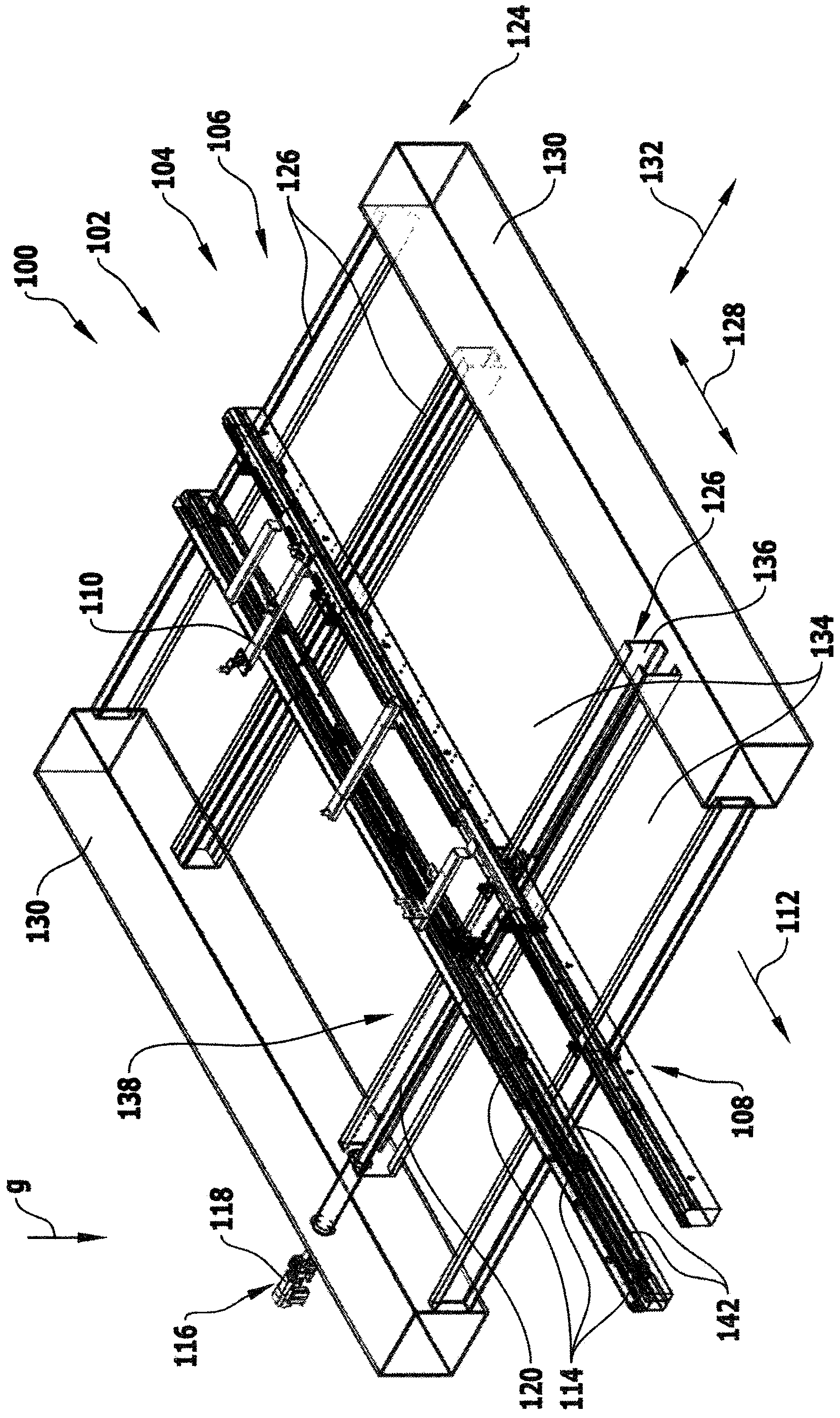

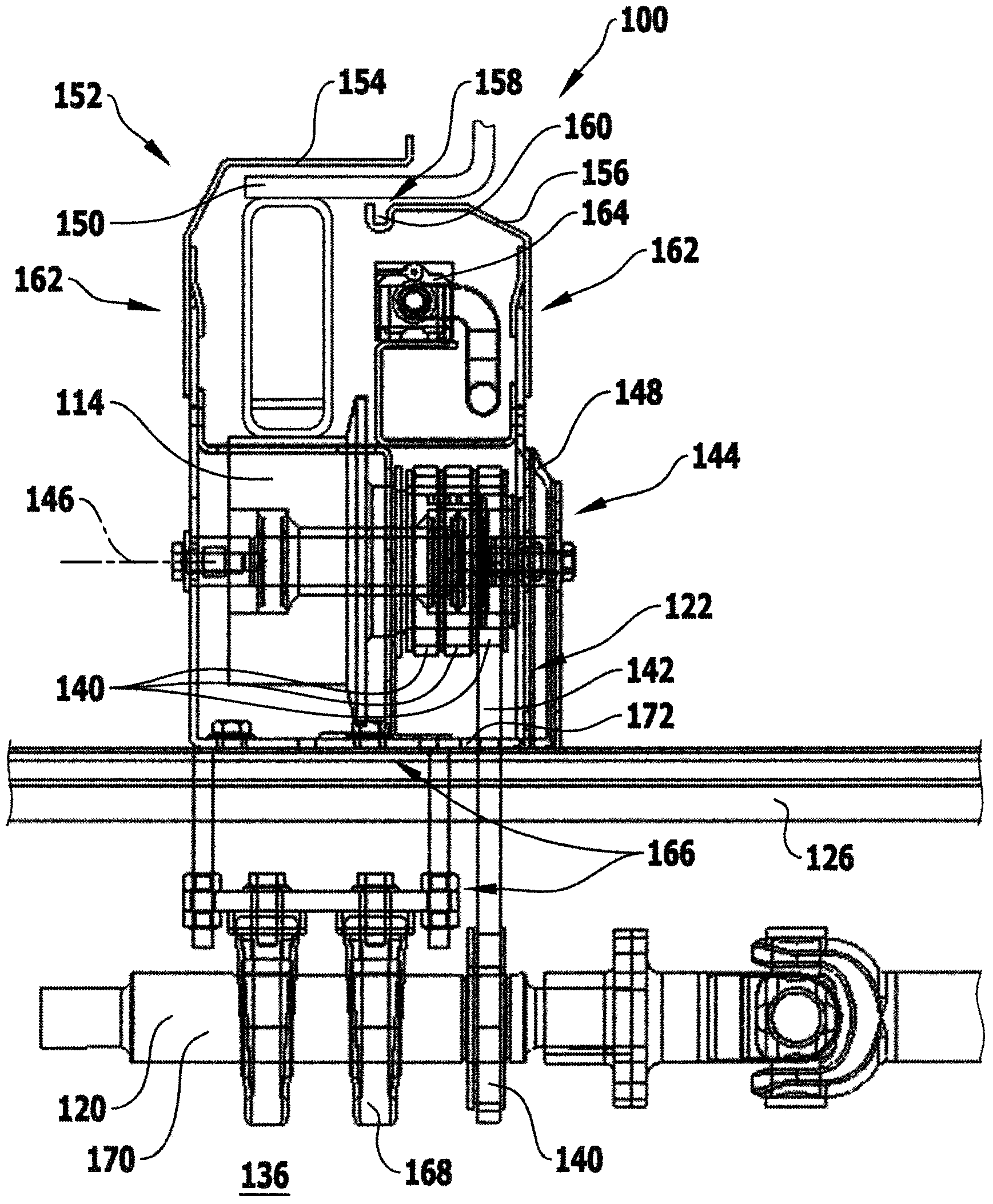

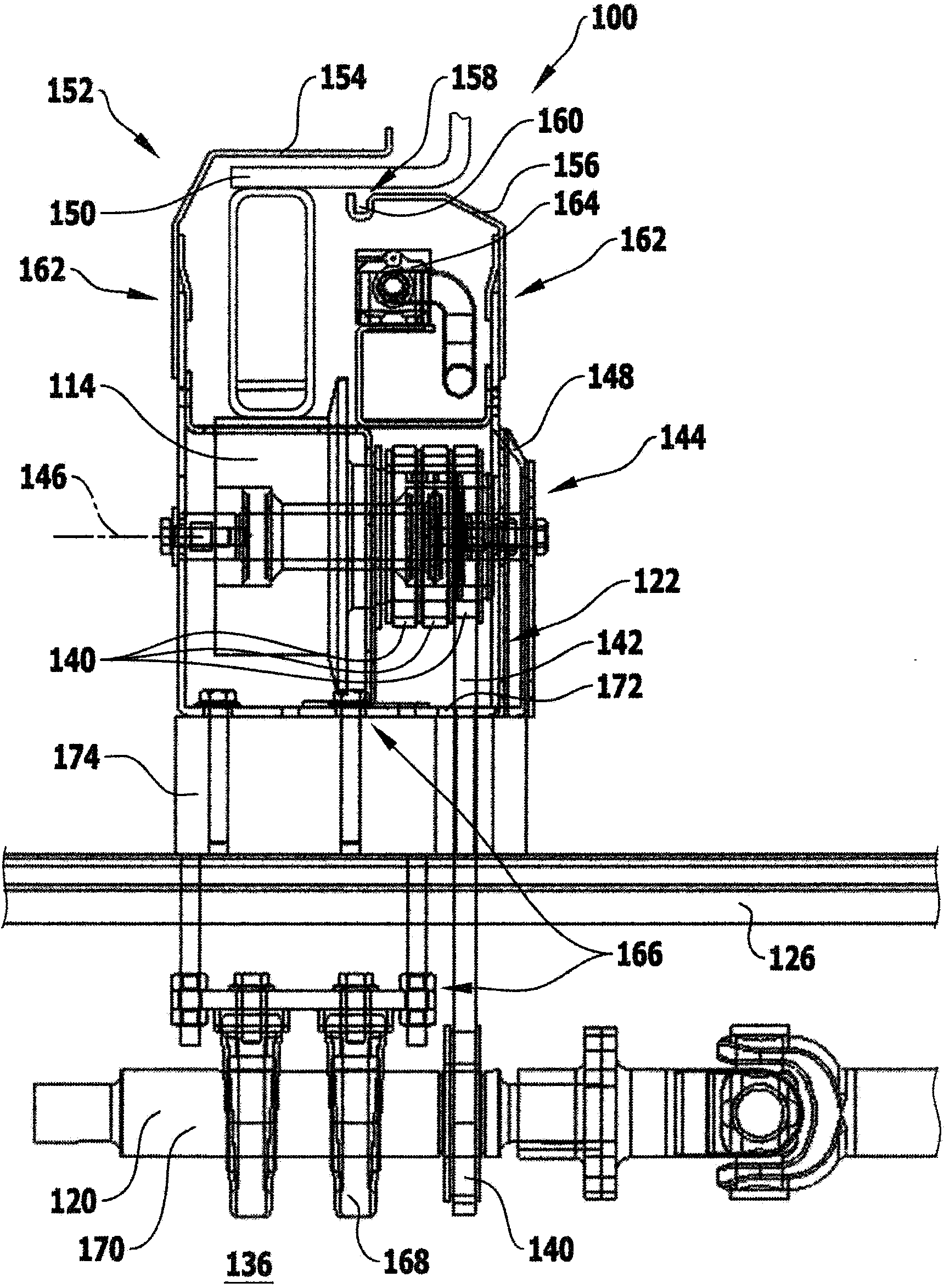

[0161] For example in figure 1 and Figure 4 The coating and / or processing plant partially shown in FIG. 1 , designated as a whole by 100 , is designed, for example, as a painting plant 102 .

[0162] The coating and / or processing plant 100 includes a coating and / or processing chamber 104 in which workpieces (not shown) can be coated and / or processed.

[0163] In particular, the workpieces can be coated or processed in the coating and / or processing region 106 of the coating and / or processing chamber 104 .

[0164] For conveying the workpieces through the coating and / or processing chamber 104 , the coating and / or processing device 100 includes a conveyor device 108 , for example configured as a roller conveyor device 108 .

[0165] The workpieces can be arranged on a workpiece carrier 110 and conveyed in a conveying direction 112 through the coating and / or processing chamber 104 by means of the conveying device 108 .

[0166] The transport device 108 comprises a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com