A Parameter Analysis Method Using Microwave Assisted Grinding Boronite

A microwave-assisted, parameter analysis technology, applied in the field of mineral processing, can solve the problems of large investment, high energy consumption, and low energy utilization rate in the crushing and grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The composition of boronite contains B by weight percentage 2 o 3 6%, Fe 2 o 3 28%, MgO 37%, SiO 2 28%, Al 2 o 3 2%, CaO 0.7%, MnO 0.1%, the rest is impurities, iron grade TFe24%; particle size is 15~25mm;

[0031] Carry out microwave roasting of boronite in a microwave oven, with a microwave power of 1500~2500W, heating to a temperature of 450~650°C, and a feeding amount of 50~250g;

[0032] Use a ball mill to grind the boron ore after microwave treatment, the ball mill speed is 96±2 r / min, the grinding time is 5min, and then screen out the part with a particle size of ≤75μm;

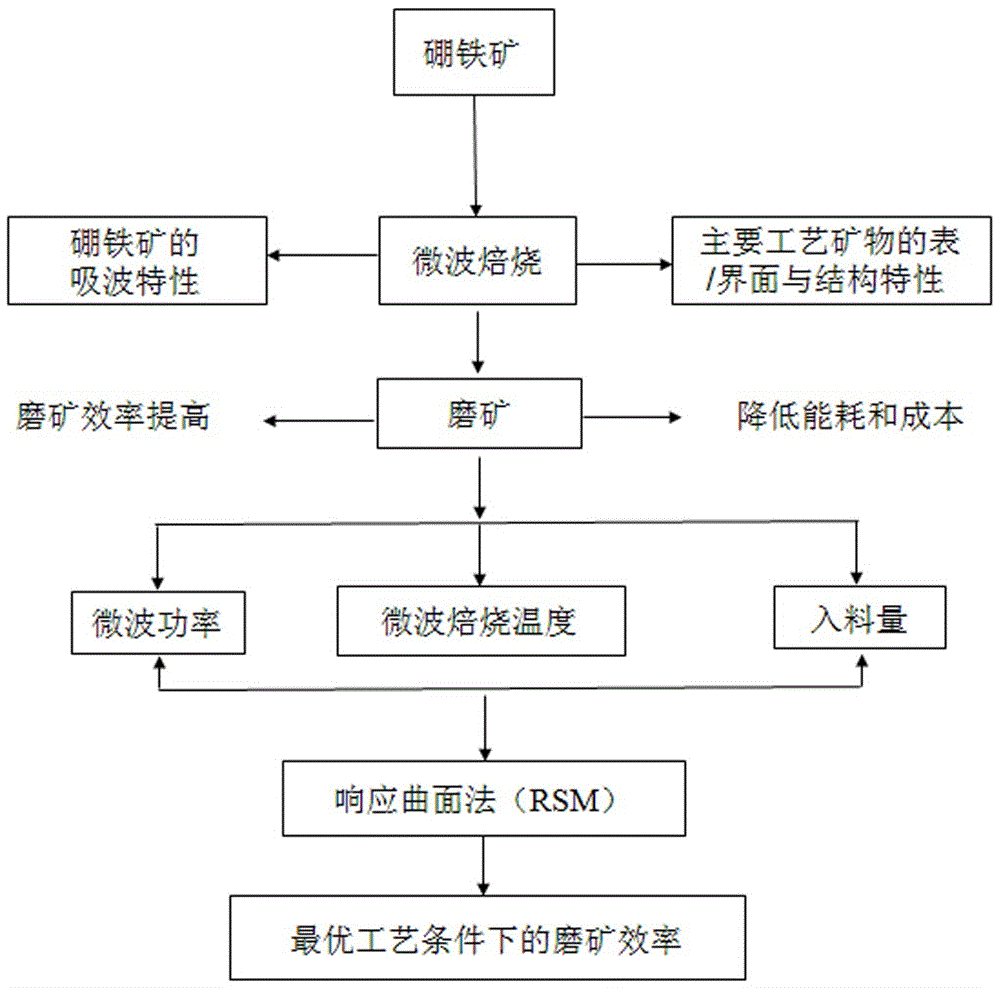

[0033] The central combination design of the response surface method is used to optimize the ball milling process of boronite. The three influencing factors selected in the experiment are: microwave power X 1 , the unit is W, the microwave roasting temperature X 2 , the unit is ℃, the amount of feed X 3 , the unit is g, and the response value Y of the experiment is set as the yield ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com