Pressing plate clamp

A technology of pressing plate clamps and pressing tubes, which is applied in the field of pressing plate clamps, can solve problems such as inability to improve production efficiency, inconvenient operation, and unsatisfactory fixtures, etc., and achieve the effects of convenient operation, fast clamping, fast compression and loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

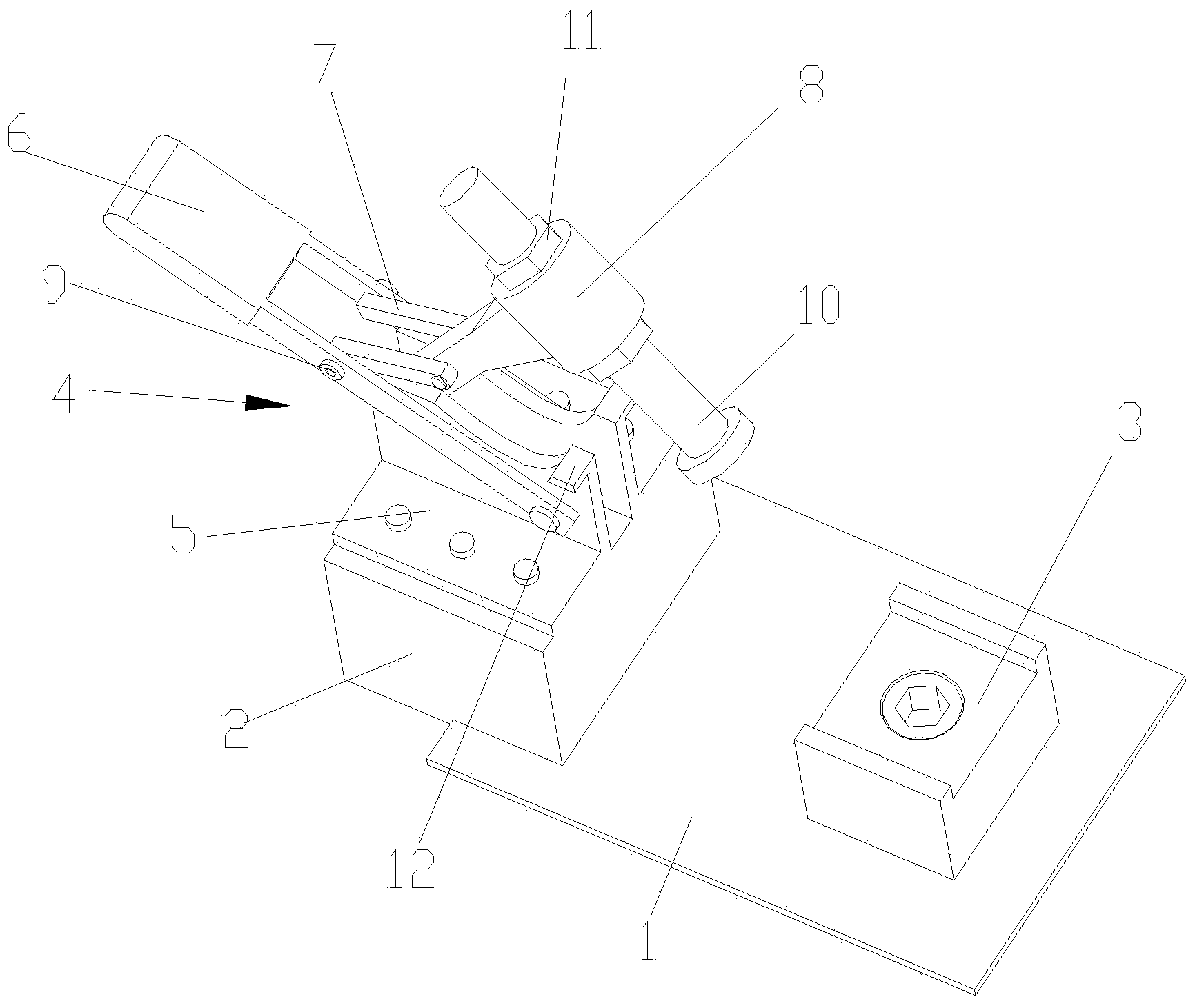

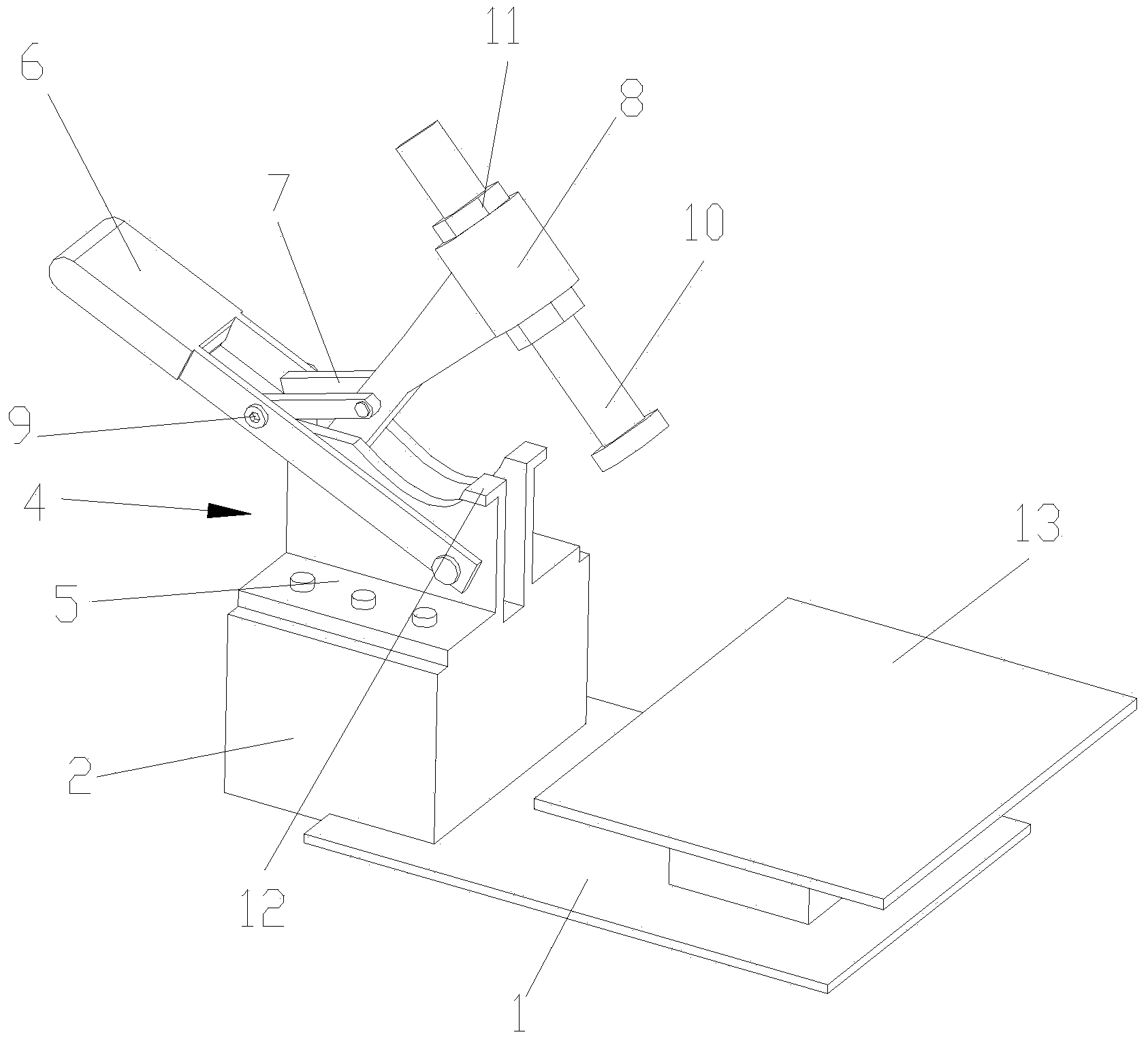

[0014] as attached figure 1 Shown is a clamping fixture according to the present invention, including a bottom plate 1 and a base 2, the base 2 is arranged on one side of the bottom plate 1; the bottom plate 1 is also provided with a pressing table 3 at the front end of the base; the base 2 There is a pressing device 4; the pressing device 4 includes a bracket 5, a handle 6, a connecting rod 7 and a pressure tube 8; the bracket 5 is arranged on the base 2; the handle 6 is connected to the bracket 5 through a bolt 9 One end of the connecting rod 7 is connected to the handle 6, and the other end is connected to the pressure tube 8; one end of the pressure tube 8 is connected to the bracket 5, and the other end is provided with an adjustment pressure rod 10; the pressure tube 8 and The mating joint of the base 2 is an interference fit; an adjustment nut 11 is also provided between the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com