Master plate clamp of vertical type milling machine

A vertical milling machine, relying on the template technology, applied in the direction of clamping, manufacturing tools, copying process control system, etc., can solve the problems of inaccurate tool centering, decreased machining accuracy, and damaged tools, so as to achieve simple structure and improve machining accuracy , the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

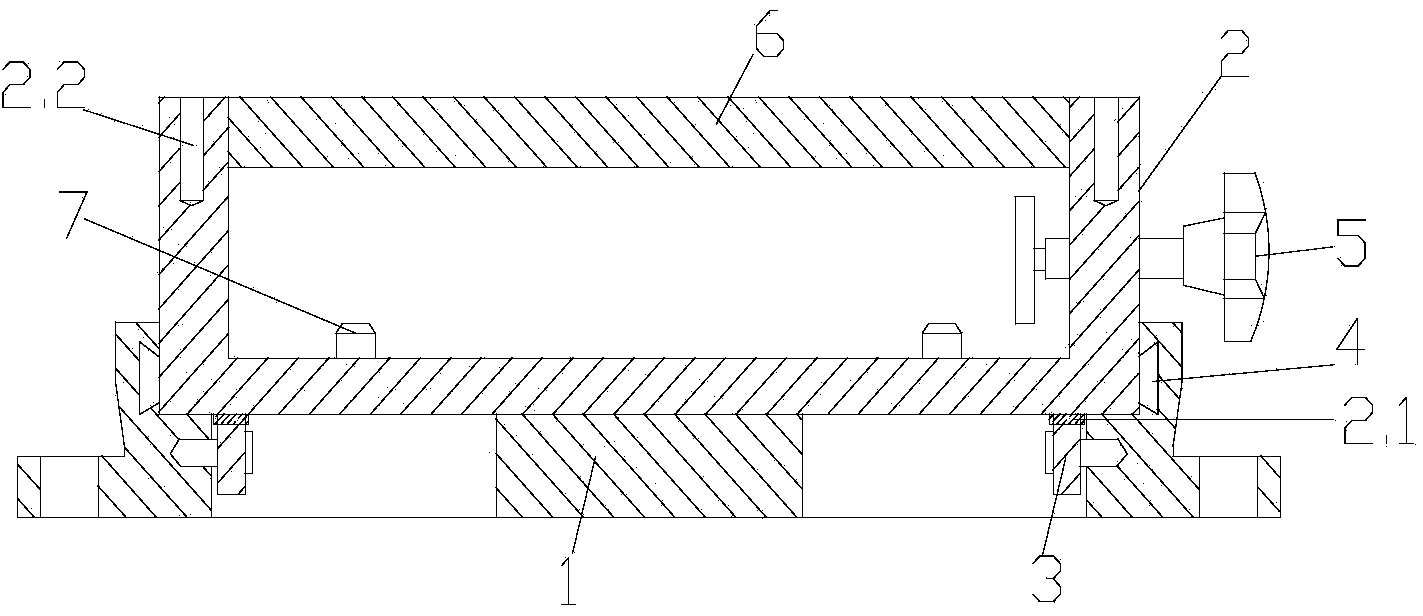

[0012] Such as figure 1 The vertical milling machine shown in the formwork fixture includes the base 1 and the U-shaped sliding seat 2 that are movably connected to the base 1. The top surface of the base 1 is provided with a fixing plate connected to the U-shaped sliding seat 2. The base 1 and the milling machine table are connected by screws. Fixed, gear 3 and chute 4 are provided on the inner side of the fixed plate, rack 2.1 matched with the gear 3 is provided at the opposite position on the bottom surface of U-shaped slide seat 2, and limit blocks are provided at both ends of rack 2.1, U-shaped slide seat 2 The outer walls of the vertical plates on both sides are provided with protrusions that match the chute, and the vertical plates on one side are also provided with fastening bolts 5, and the top surfaces of the vertical plates on both sides are also provided with threads that are detachably connected to the backing plate 6 Holes 2.2, U-shaped sliding seat 2 are provide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap