Positioning adjustment mechanism and method for adjusting light distribution mirror in hot plate welding lamp

A technology of positioning adjustment and hot plate welding, applied in the field of adjusting light distribution mirrors, can solve the problems of large cumulative error, inconvenient lamp adjustment, cumbersome steps, time-consuming and laborious, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings. Those skilled in the art should understand that the embodiments are only for illustration and do not constitute any limitation to the present invention.

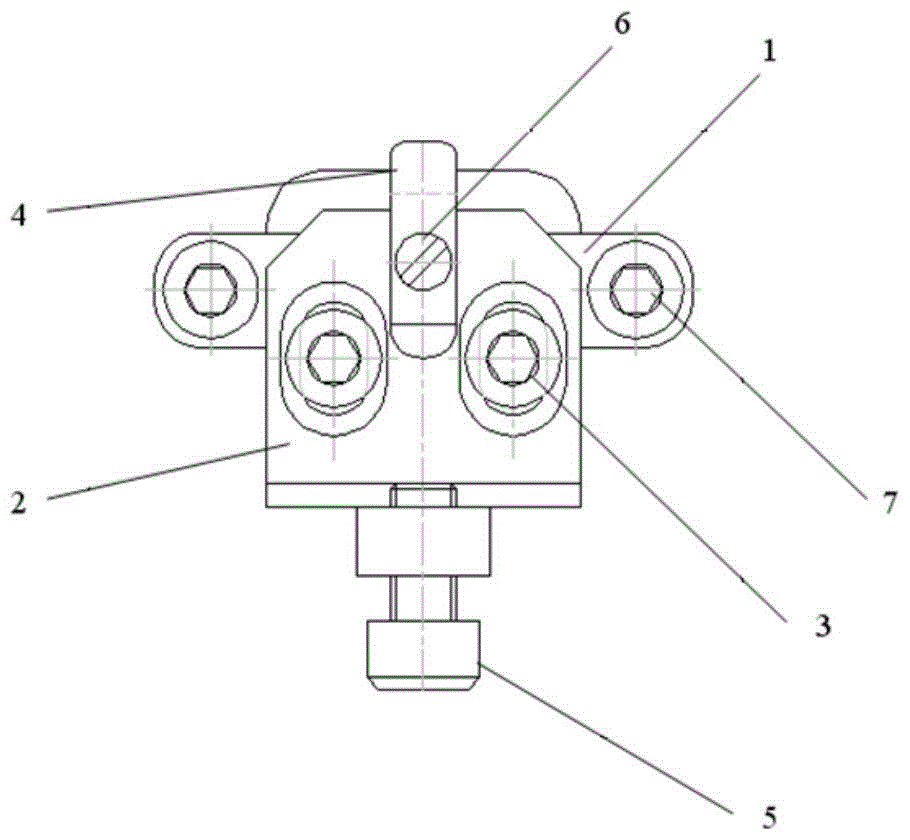

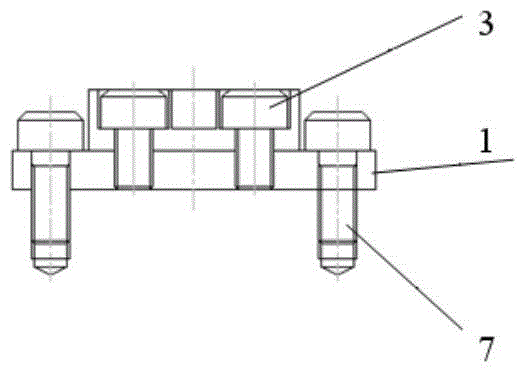

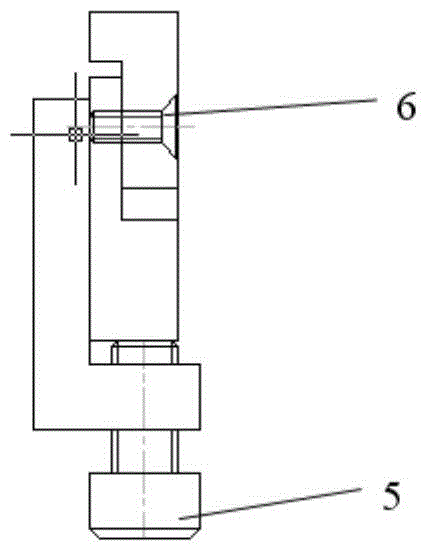

[0057] attached Figure 1-3 Middle: a positioning adjustment mechanism in a hot plate welding lamp, including a stainless steel bottom plate 1, through which the positioning adjustment mechanism is fixed on the periphery of the mold epoxy mold cavity on the hot plate welding mold; A heat-resistant aluminum alloy connection plate 2 with a waist hole is arranged on the stainless steel bottom plate 1, and the aluminum alloy connection plate 2 can move relative to the stainless steel bottom plate 1; fastening screws 3 pass through the waist hole to connect the aluminum The alloy connecting plate 2 is fixed to the stainless steel bottom plate 1; an adjusting screw 5 is provided at the rear end of the aluminum alloy connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com