A fully automatic combined oil press

An oil press, fully automatic technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of metal pollution, high labor intensity, etc., achieve high automation, reduce labor intensity and labor costs, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

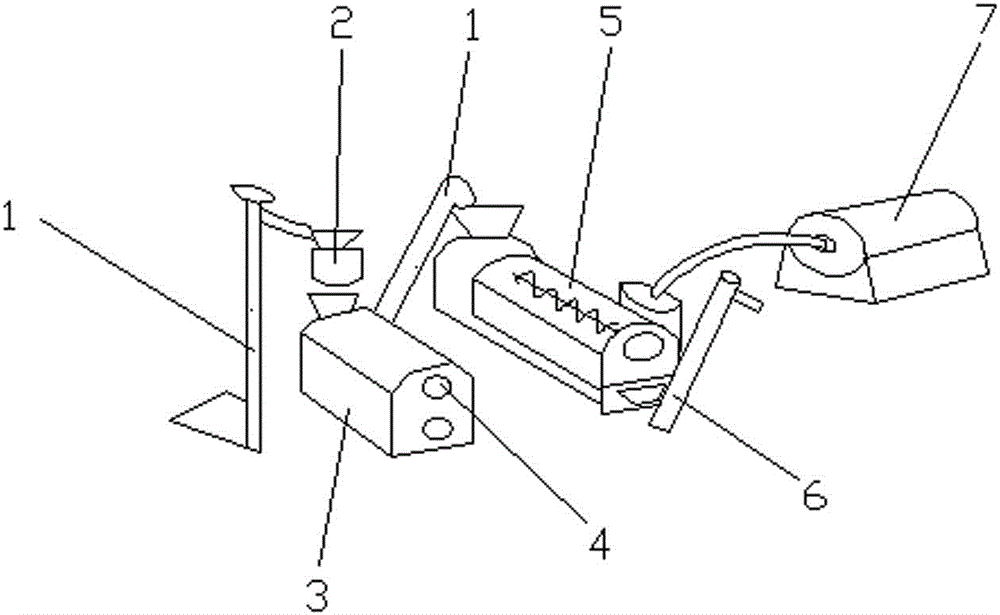

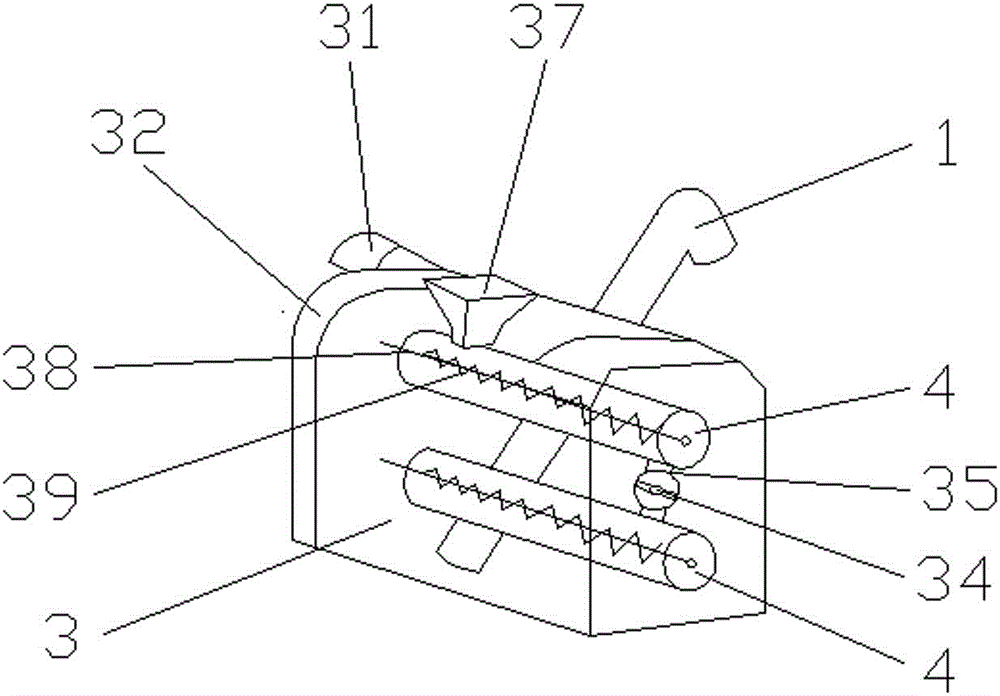

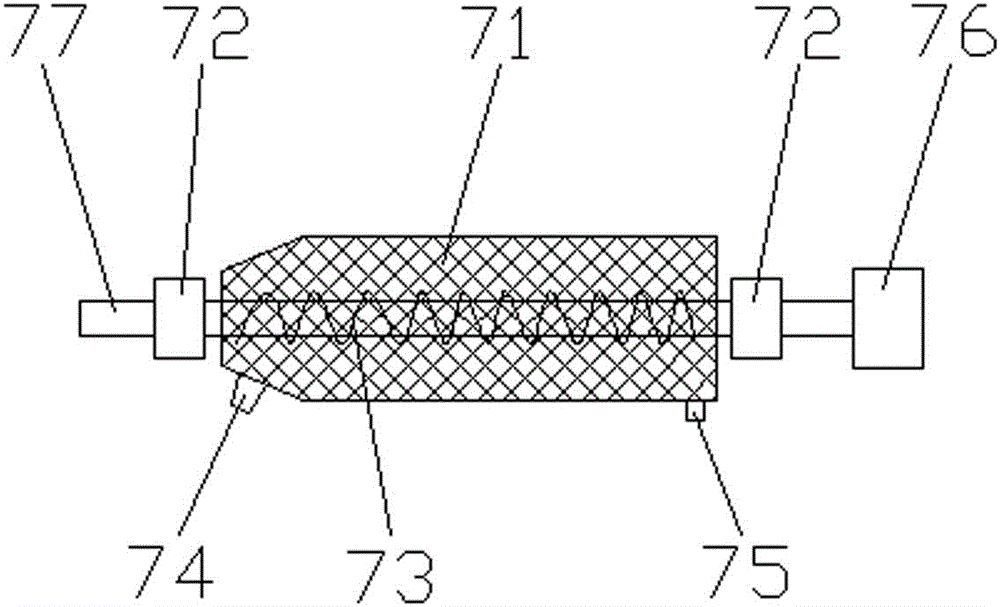

[0018] see figure 1 , figure 2 and image 3 , a fully automatic combined oil press, including a high-frequency heating automatic device 3, which includes two connected upper and lower tubular spiral woks 4, and a spiral wok 4 is provided in the middle The stirring rod 38 is wound with a red copper wire 39 for heating, and the two spiral frying pans 4 are connected by a pipe 35, and a middle mixing knife 34 is provided on the pipe 35. Because the pipe 35 is easy to stick peanuts, causing the pipeline 35 to be blocked, the middle mixing knife 34 can clean the inner wall of the pipeline 35, and the feeding hopper 37 of the high-frequency heating automatic device 3 is connected with a pulverizer or peanut sheller 2 , the feeding port of the pulverizer or peanut sheller 2 is connected with a feeder 1, and the discharge port of the above-mentioned high-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com