Preparation method for high-barrier anti-swelling packaging bag

A high-barrier, anti-expansion technology, which is applied in packaging, transportation and packaging, chemical instruments and methods, etc., can solve the problems of packaging bags that cannot meet the application occasions, poor barrier properties, and insufficient anti-expansion ability, and achieve excellent barrier properties. Anti-expansion, low cost, smooth and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

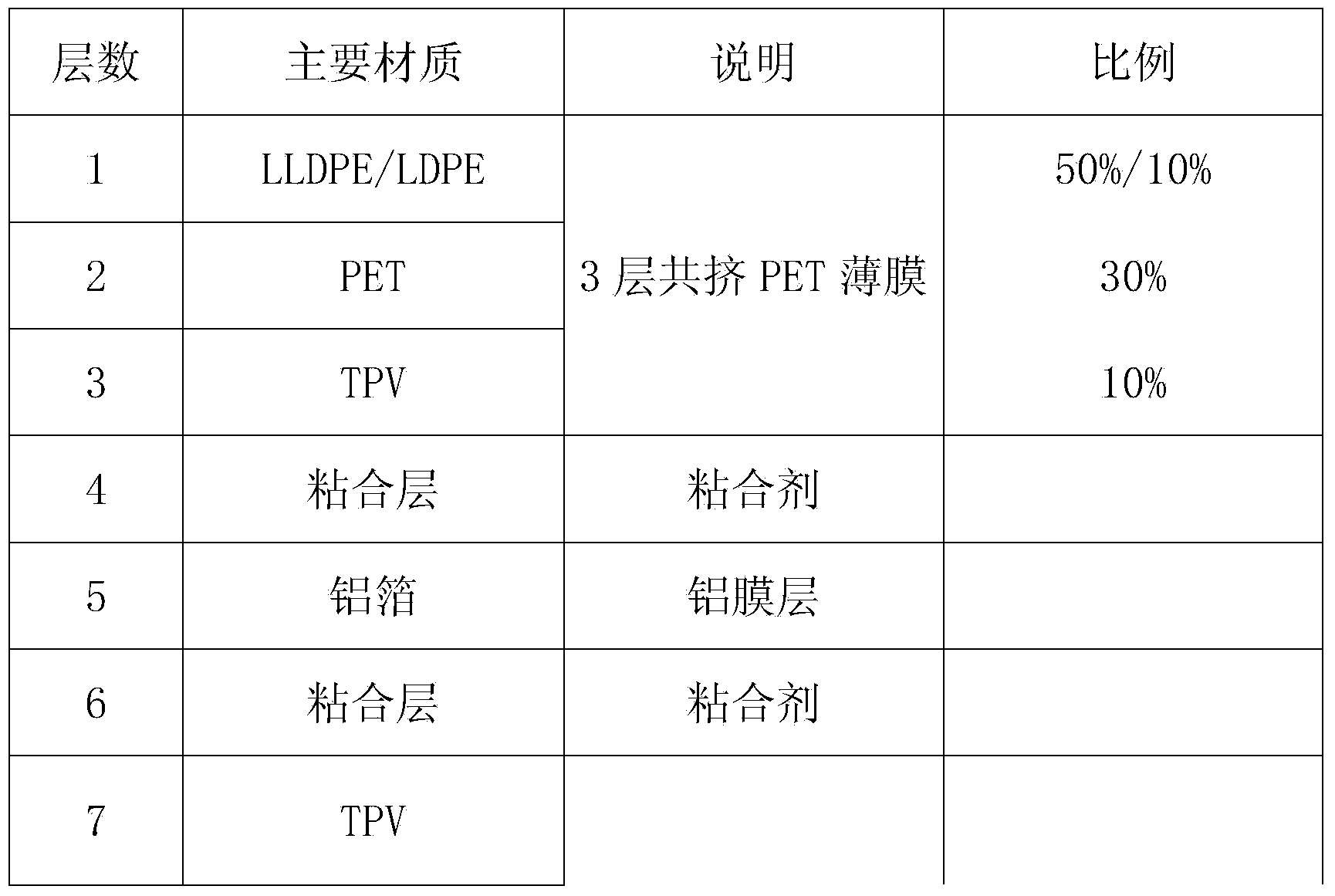

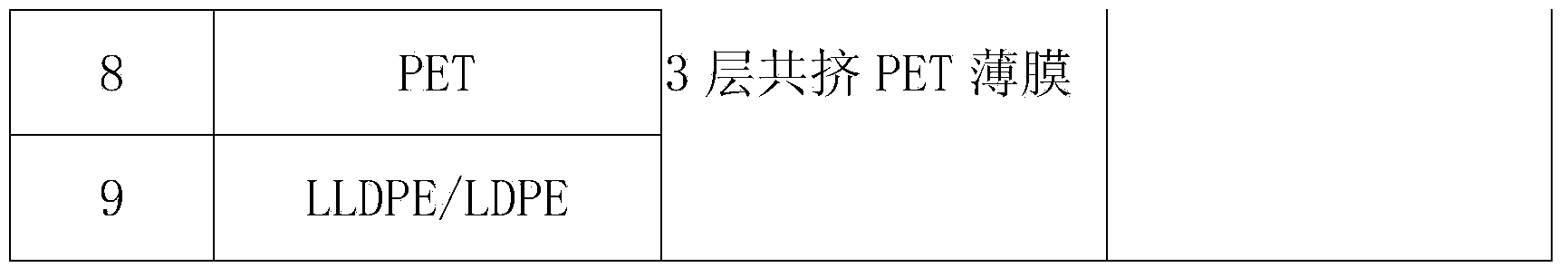

[0028] A kind of preparation method of high barrier performance anti-expansion packaging bag of the present invention, it comprises the following steps,

[0029] 1. Inner bag making:

[0030] (1) LLDPE / LDPE, PET and TPU are blown into PET film through a three-layer co-extrusion film blowing machine. The temperature is controlled between 150-170°C, the frequency of the host is between 25-35Hz, and the traction frequency is 8- 10Hz, and then through the laminating machine, use the adhesive to laminate the PET film on both sides of the aluminum foil, and then cut the laminated aluminum film into pieces;

[0031] (2) Blow LDPE, TiV, and PA into five-layer co-extruded PA film through a five-layer co-extrusion blown film machine. 8-10Hz, then cut into film strips with a width of 5cm and the same length as the mesh spacer;

[0032] (3) Melt and extrude the PP particles, the melting temperature is between 140-150°C, and form a film by cooling, the film is punched by a die to form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com