Special Compound Fertilizer for Flue-cured Tobacco Variety k326 and Its Application

A flue-cured tobacco variety and compound fertilizer technology, applied in the agricultural field, can solve problems such as unreasonable fertilizer type matching and nutrient distribution ratio, unfavorable tobacco leaf yield and quality, and reduced fertilizer utilization rate, so as to improve the appearance quality of tobacco leaves, good appearance quality, The effect of excellent agronomic traits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

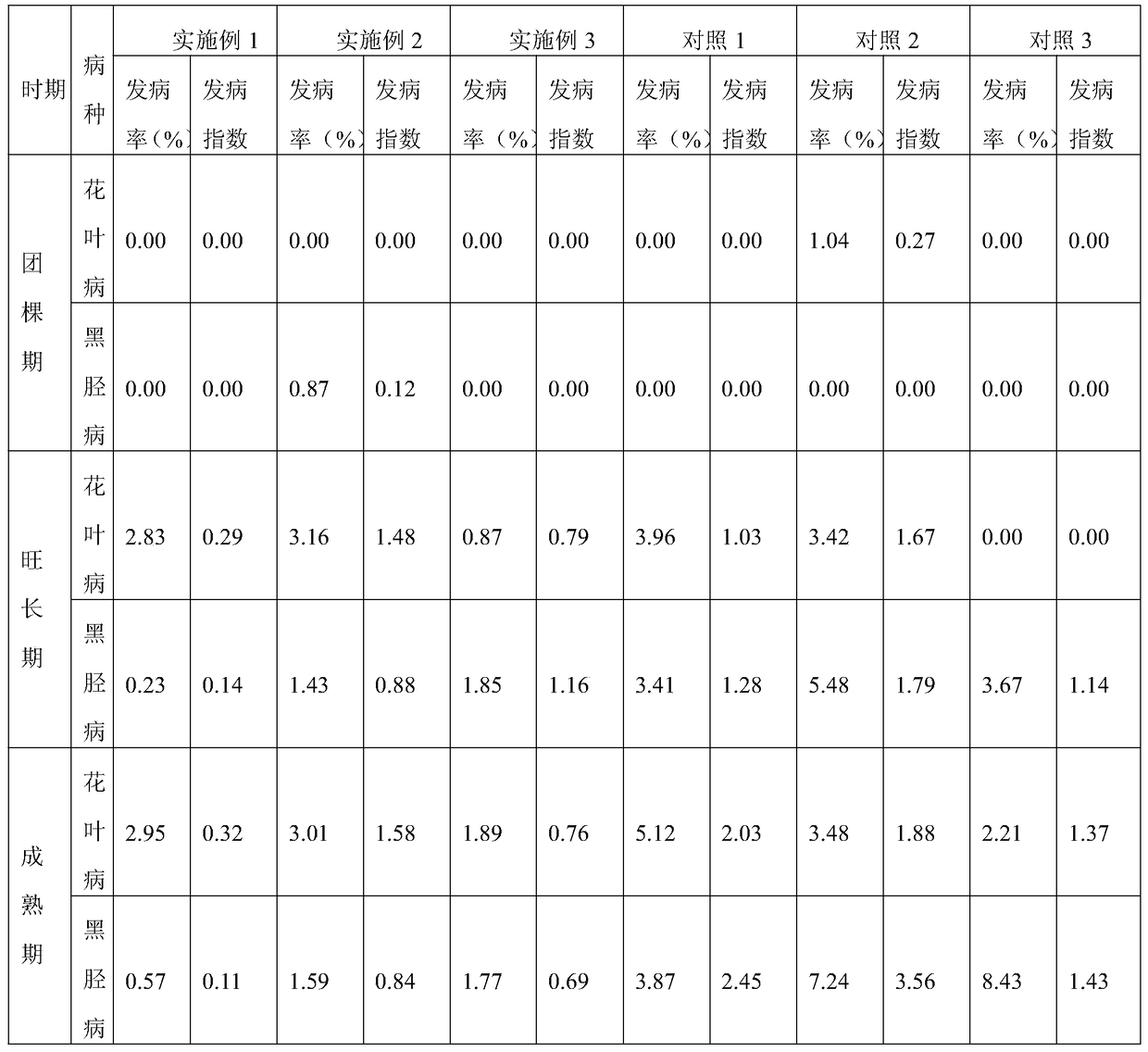

Examples

Embodiment 1

[0021] Preparation method of special compound fertilizer for flue-cured tobacco variety K326: It is made by drum steam granulation process, namely 14-16 parts ammonium nitrate, 16-18 parts diammonium phosphate, 47-49 parts potassium sulfate and 50 parts diatom The soil is pre-crushed, then mixed, and then crushed into powder. The mixed components are granulated by drum. The granulation process and conditions are as follows: steam is added to the drum, and the mixed elemental fertilizer powder is started. Agglomeration is appropriate. The roughly agglomerated powder is fed into the drying kiln through a belt for drying. The inlet temperature of the drying kiln is controlled at 140°C. The powder is further granulated and dried in the drying kiln, and then cooled by the cooling kiln. After the mesh screen, the finished product is bagged, and the particles that are too large or too small are returned and further re-granulated. The percentage content of nitrogen, phosphorus and pota...

Embodiment 2

[0024] The formulating method of special compound fertilizer for flue-cured tobacco variety K326: same as Example 1.

[0025] For medium fertility fields (the grading standard is the second soil survey), the fertilizer with a ratio of 8:8:24 of nitrogen, phosphorus and potassium is applied during transplanting, and the application rate is 65kg / 667m. 2 , 7 days after transplanting and 15 days after transplanting, 6kg and 13kg of potassium nitrate were applied as the first top dressing, and 40 days after transplanting, 19kg of potassium sulfate was applied as the second top dressing.

Embodiment 3

[0027] The formulating method of special compound fertilizer for flue-cured tobacco variety K326: same as Example 1.

[0028] For low fertility fields (the grading standard is the second soil survey), the fertilizer with a ratio of nitrogen, phosphorus and potassium of 8:10:32 is used for preparation when transplanting, and the application rate is 70kg / 667m 2 , 7 days after transplanting and 15 days after transplanting, 6kg and 13kg of potassium nitrate were applied as the first top dressing, and 40 days after transplanting, 19kg of potassium sulfate was applied as the second top dressing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com