Preparation method of cellulose hydrophobic material

A hydrophobic material and cellulose technology, which is applied in the field of preparation of cellulose hydrophobic materials, can solve the problems of complex preparation and non-biodegradable cellulose hydrophobic materials, and achieve the effects of good hydrophobic performance, simple preparation method, and improved surface roughness

Active Publication Date: 2015-02-18

INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

View PDF6 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] The technical problem to be solved by the present invention is to provide a preparation method of cellulose hydrophobic material which is complet

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

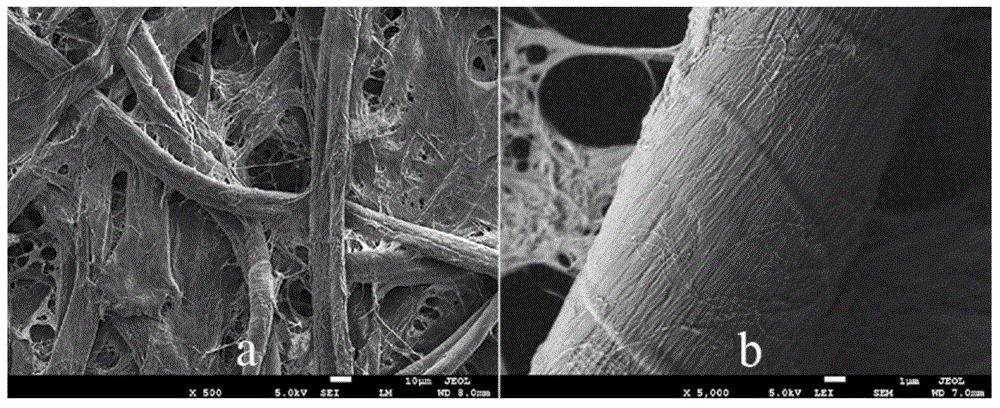

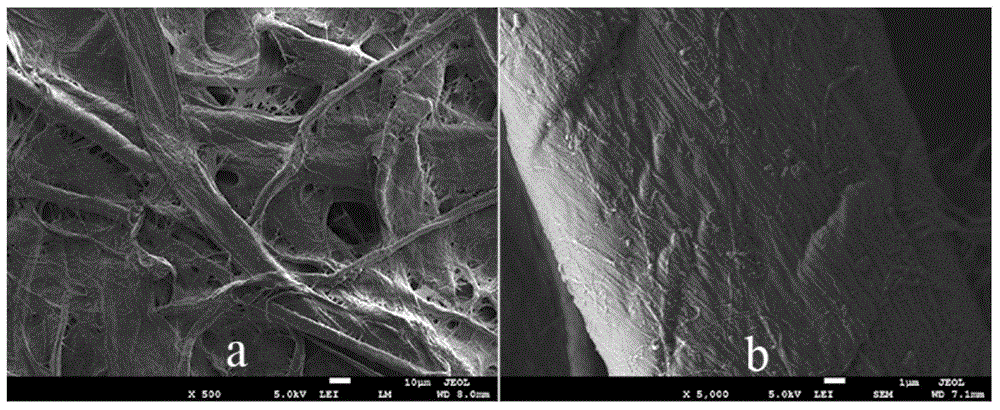

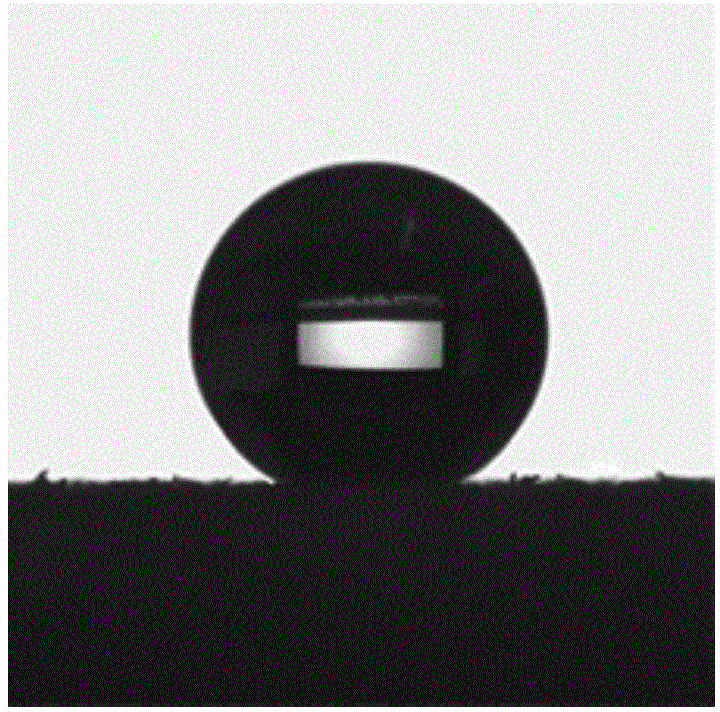

The invention discloses a preparation method of a cellulose hydrophobic material. The cellulose hydrophobic material is prepared by reacting cellulose and epoxidized vegetable oil. Compared with the prior art, the method has the advantages of wide sources and low price of the vegetable oil raw material; the prepared cellulose hydrophobic material has nanoparticle structures on the surface and has high surface roughness and favorable hydrophobicity, the contact angle reaches 137-155 degrees; the nanoparticles formed by the cellulose surface fibers enhance the roughness; and after the material is immersed in water for 48 hours, the saturation water absorptivity is 6-17 wt%, and the material can still keep the hydrophobicity.

Description

technical field [0001] The invention belongs to the field of material synthesis, and in particular relates to a preparation method of a cellulose hydrophobic material. Background technique [0002] Cellulose is one of the most abundant biomass resources in the world, and has the advantages of non-polluting and degradable. There are many hydroxyl groups on the surface of cellulose, so it is easy to modify cellulose to make it a hydrophobic material. Hydrophobic cellulose fibers are currently in high demand and are widely used in outdoor waterproof gear, raincoats, stain-resistant products, and bandages. Hydrophobic materials have shown their unique advantages, and their preparation and application have attracted extensive attention. [0003] Hydrophobic cellulose materials are made by chemically modifying the fibers on the surface of cellulose to make the surface fibers hydrophobic, and the pores in the fibers can still maintain air permeability. Modification of cellulose ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G59/02

Inventor 刘鹤黄旭娟王爱婷商士斌宋杰

Owner INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com