Road-bridge transition section structure of high-grade highway suitable for short construction period condition in cold region

A high-level, transitional technology, applied in the direction of roads, bridges, roads, etc., can solve problems such as support surface voids, difficulties, vehicle instability, etc., to improve performance and service life, good economic benefits, and reduce bridge head jumps car effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

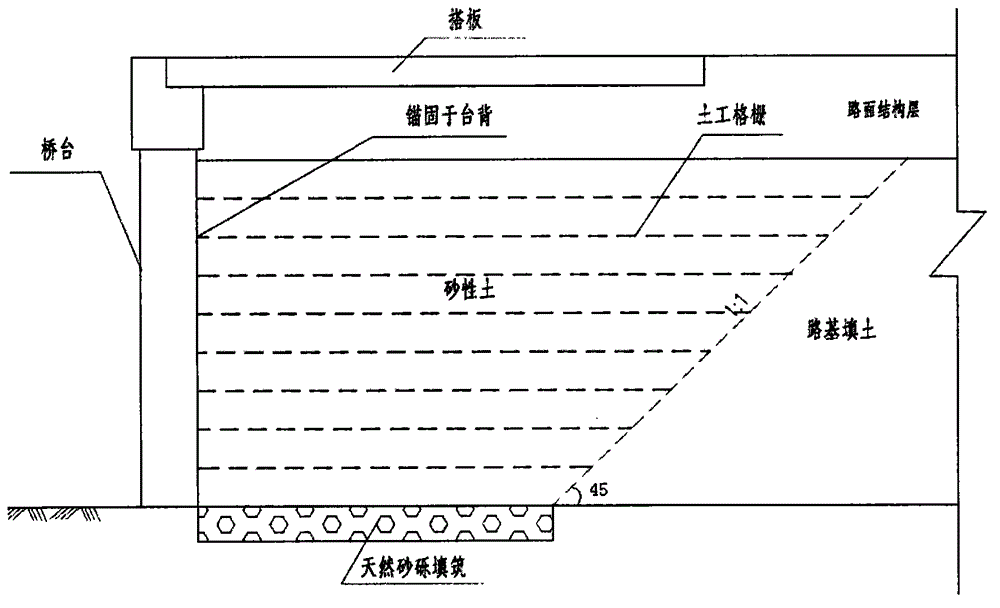

[0024] Attached below Figure 1-3 Specific embodiments of the present invention will be described in detail.

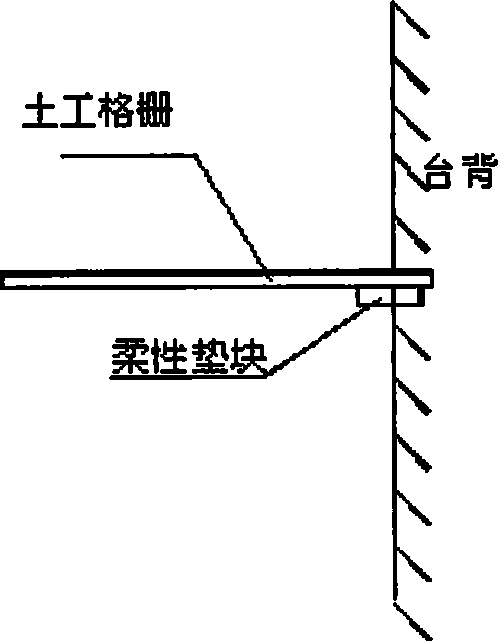

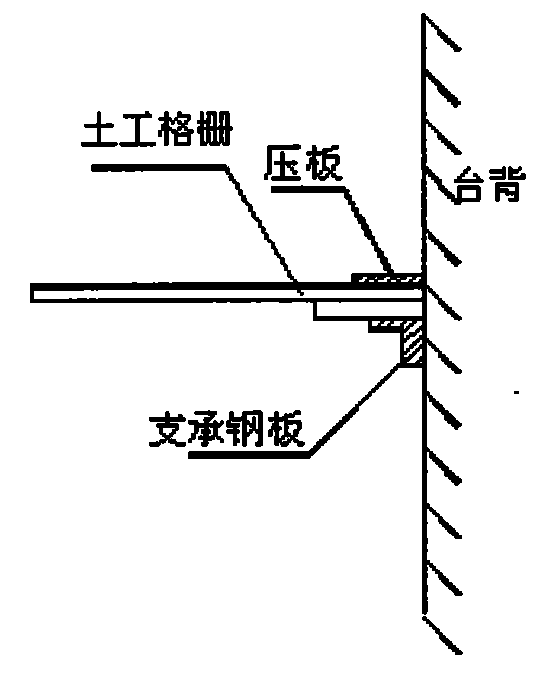

[0025] The invention includes an abutment and a roadbed, one side of the abutment is a bridge, and the other side is connected to the road through a roadbed, that is, the roadbed is arranged on the road side of the abutment, and the roadbed includes a foundation, a soil foundation, a road surface structure layer and a board, and the foundation is lower than The base of the abutment is to dig down the road groove on one side of the base, and fill the road groove with natural gravel. Foundation, the soil foundation includes the reinforced sand layer and the subgrade filling soil, the pavement structure layer is arranged on the soil foundation, the board is embedded in the pavement structure layer, and the pavement of the upper plane, the upper plane of the bridge abutment and the pavement structure layer The bottom surface of the reinforced sand layer is in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com