A comb-type vibration-absorbing displacement bridge telescopic device

A telescoping device and comb-tooth-type technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problem of damage to the beam body caused by the addition of comb-tooth plates across the seams, and damage to the comb-tooth plates across the seams, which affects the shock absorption of the shock-absorbing displacement components Effectiveness, stability, and weak anti-pull-off ability, etc., to achieve good versatility and economy, prevent bolt pull-off, and enhance fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the content of the specific embodiments is not intended to limit the protection scope of the present invention.

[0029] The invention relates to a comb-tooth type vibration-absorbing displacement bridge telescopic device, which is convenient to install, saves time and effort; meanwhile, has good shock resistance and reduces damage to the bridge.

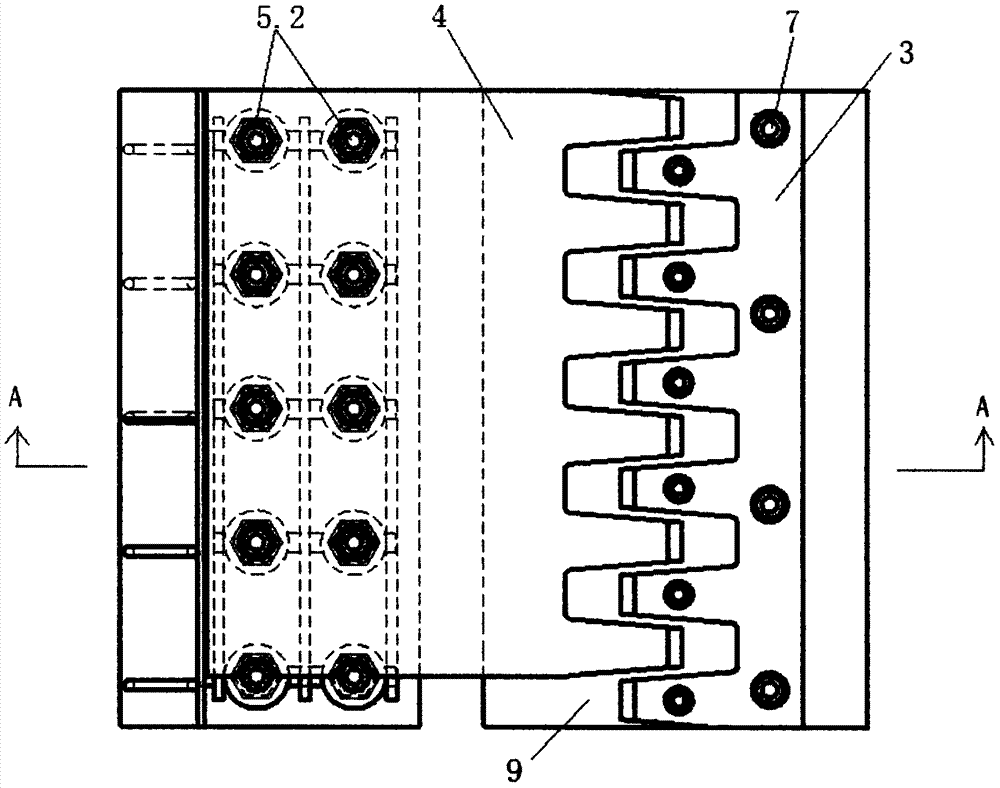

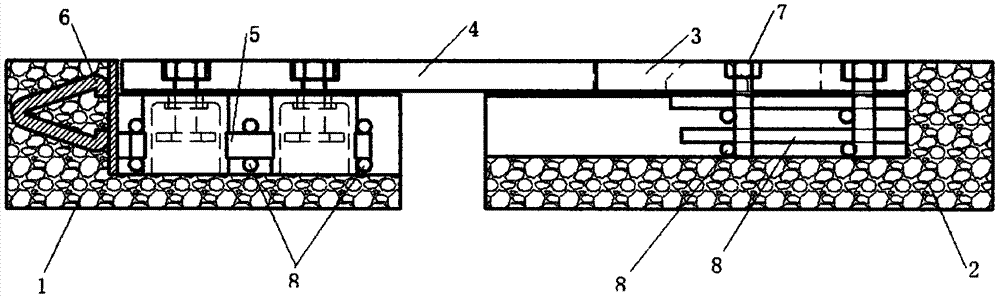

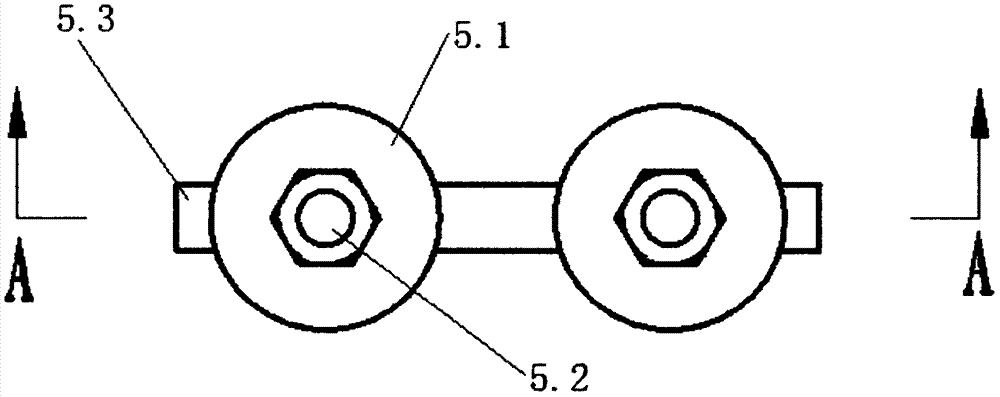

[0030] Such as figure 1 and 2 As shown, the comb-type shock-absorbing displacement bridge expansion device of the present invention includes a fixed comb-tooth plate 3 , a gap-spanning comb-tooth plate 4 , a shock-absorbing displacement assembly 5 and a baffle plate 6 . Wherein, the comb teeth of the fixed comb plate 3 and the gap-crossing comb plate 4 cross each other and have gaps. Preferably, the comb teeth front ends of the fixed comb plate 3 and the gap-spanning comb plate 4 are designe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com