Method for processing soft foundation of hydraulic structure

A technology for the treatment of hydraulic structures and soft foundations, applied in similar engineering fields, can solve the problems of insufficient foundation stability and impermeability stability, affecting the normal operation and safety of buildings, and restrictions on construction period arrangements, so as to reduce the overall stability. resistance, foundation deformation suppression, and the effect of solving low bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

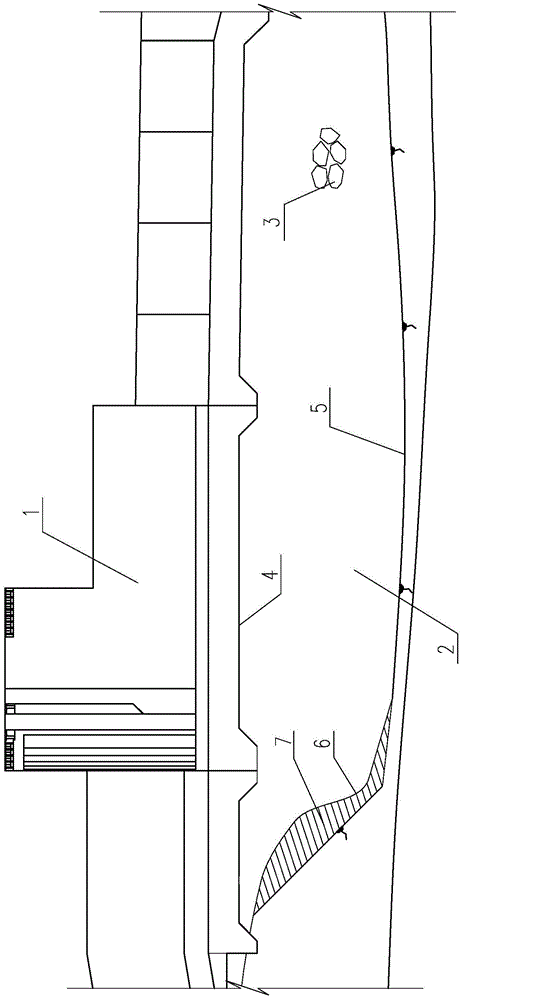

[0017] like figure 1 As shown, the present embodiment is a method for soft foundation treatment of hydraulic structures, using dry poor sand and gravel material 3 to replace the concrete and other replacement materials used in the soft foundation treatment of traditional hydraulic structures, improving the hydraulic structure 1 and foundation Stress at the contact point, suppress foundation deformation and ensure foundation stability. The specific construction method is as follows:

[0018] a. Excavation of the foundation: Excavate the weak stratum 2 with a relatively shallow buried depth in the direct bearing layer of the hydraulic structure 1, and also excavate the weak stratum 2 with a buried depth of about 20m and continuous distribution in the foundation; Permanently eliminate engineering problems such as poor bearing capacity and poor anti-earthquake liquefaction ability caused by weak strata 2.

[0019] In excavating the weak stratum 2, when encountering the silt and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com