Seepage prevention structure and method for periphery of floor-passing-through pipeline

A technology for floors and pipes, which is applied in the field of anti-seepage structure and anti-seepage around the pipes passing through the floor, which can solve the problems of affecting the visual effect, difficult operation, and difficulty in achieving the expected construction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

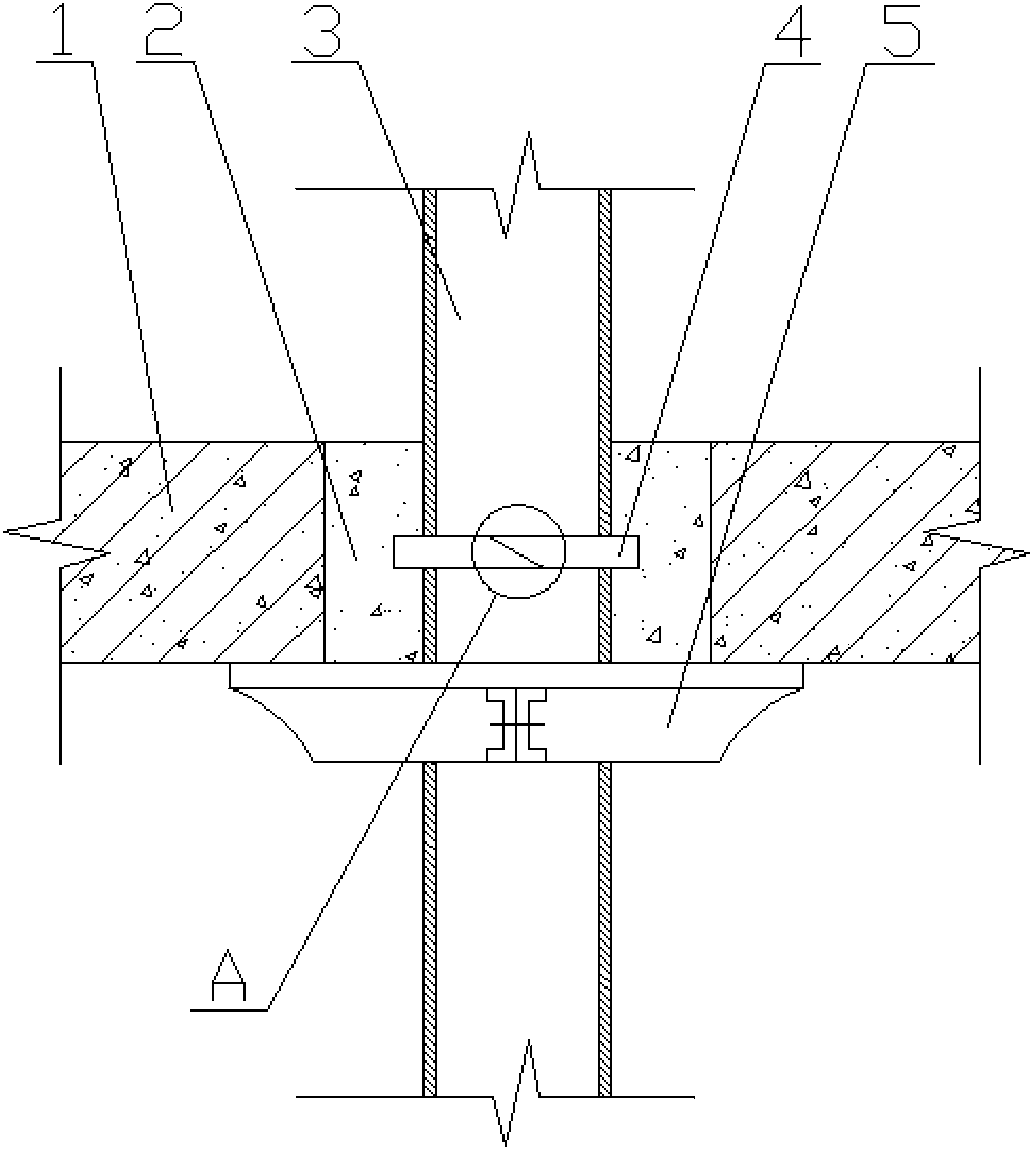

[0037] figure 1 It is an anti-seepage structure suitable for vertically penetrating floor pipes. Wherein the floor-penetrating pipe 3 is vertically placed in the middle of the floor-penetrating hole 2 reserved on the concrete floor 1, and the water-expanding water-stop strip 4 is wound and tightly attached to the middle part of the floor-penetrating pipe. The commercially available finished product blocking hole special formwork 5 made of plastics on the floor slab pipeline is fixed below the floor slab hole 2.

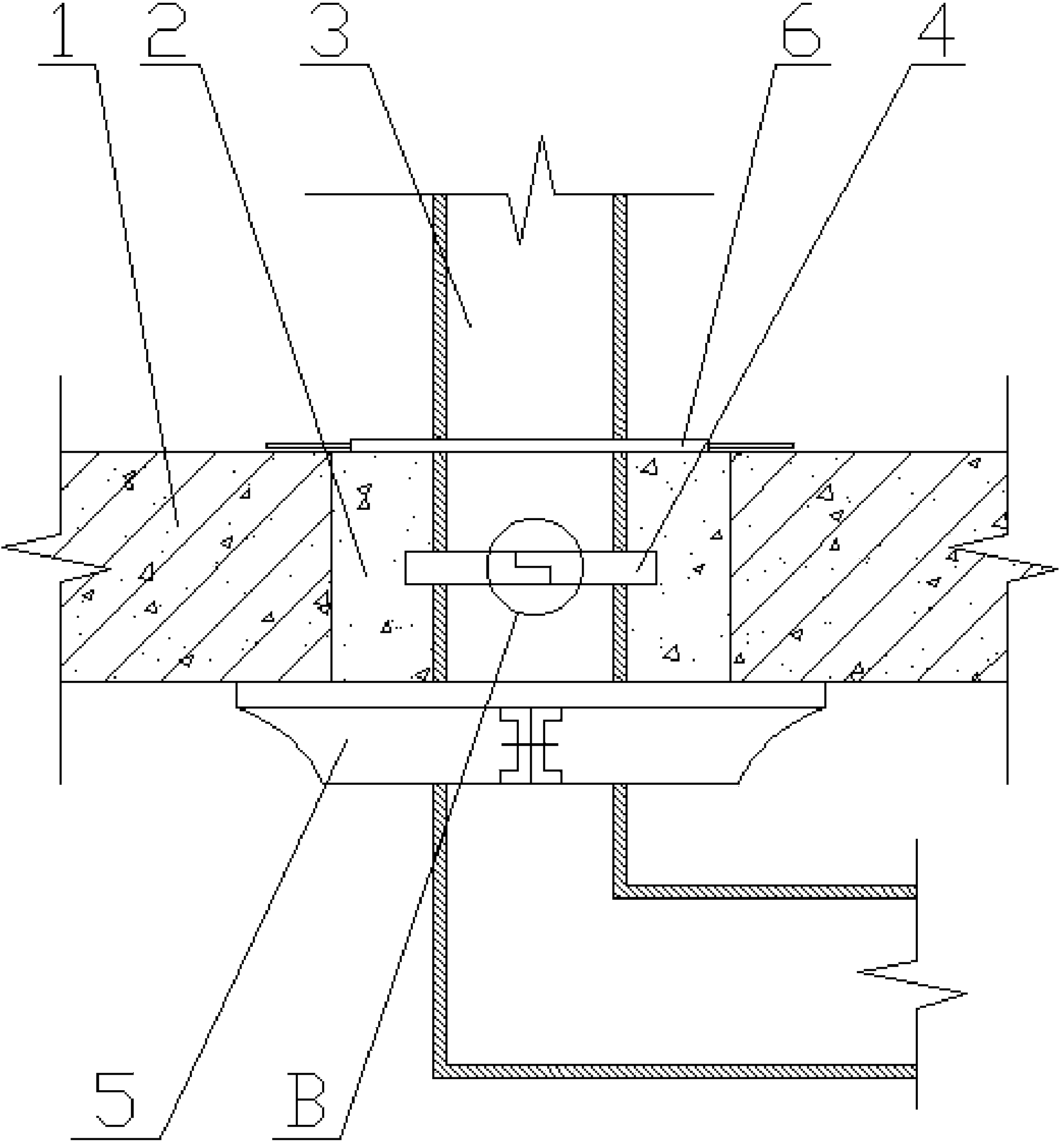

[0038] figure 2 It is a kind of anti-seepage structure suitable for pipes passing through the floor horizontally. Wherein the floor-penetrating pipe 3 is placed vertically in the middle of the floor-penetrating hole 2 reserved on the concrete floor 1, and protrudes horizontally below the concrete floor 1, and the water-expanding water-stop strip 4 is wound and adhered to the middle part of the floor-penetrating pipe. Block the protruding end of the pipeline throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com