On-line liquid viscosity and density detection probe

A technology for detecting probes and liquid viscosity, applied in measuring devices, material analysis by measuring buoyancy, flow characteristics, etc., can solve problems such as difficulty in meeting industrial field test requirements, inconvenience in use, etc., and solve the problem of online measurement of liquid viscosity and density. , eliminate the influence, the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

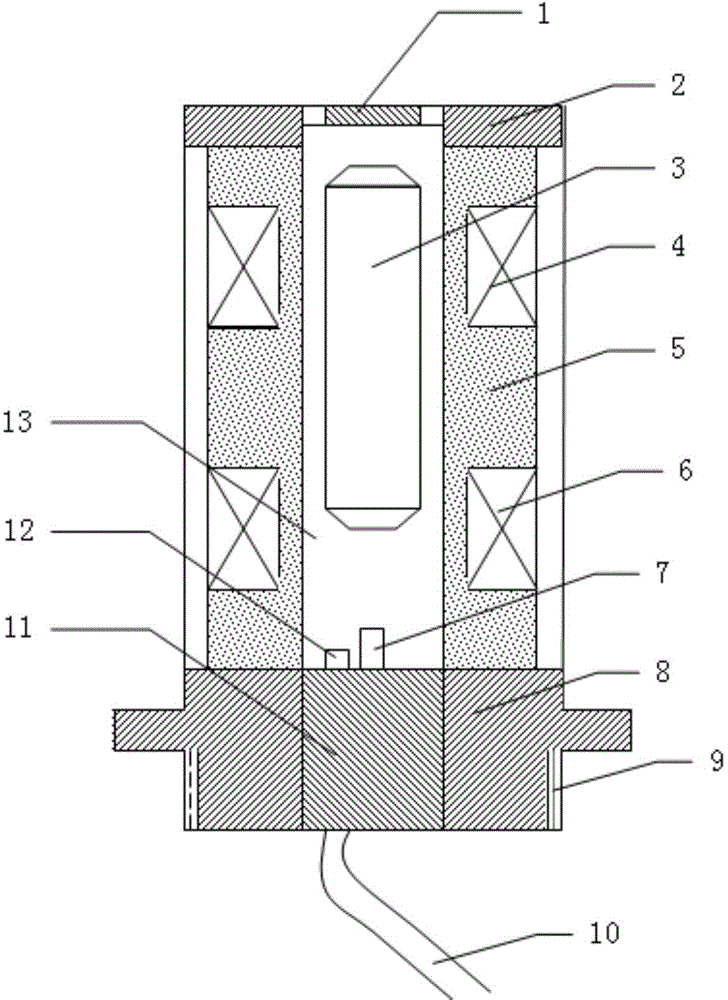

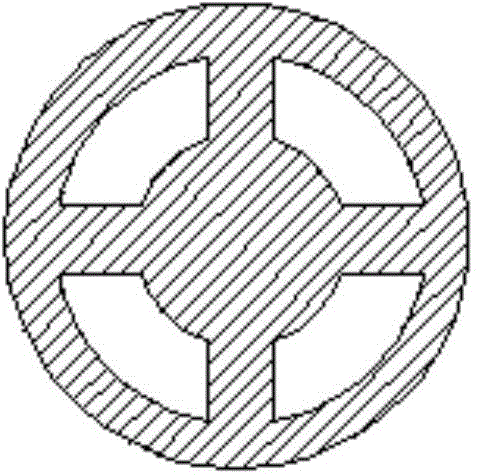

[0022] like figure 1 As shown, a liquid viscosity density on-line detection probe includes a coil bobbin 5, and the two ends of the coil bobbin 5 are respectively provided with an upper end cover 2 and a lower end cover 8, and the coil bobbin 5 is surrounded by the upper end cover 2 and the lower end cover 8. The chamber is used as a measuring chamber 13, and the upper end opening of the measuring chamber 13 is used as a liquid inflow port. The lower end of the measuring chamber 13 is sealed by a lead seat 11, and a moving float 3 made of a magnetically conductive material is provided in the measuring chamber 13. When measuring An ultrasonic sensor 7 and a temperature sensor 12 are installed on the lead wire seat 11 at the lower end of the chamber 13, and the circuit lead wires 10 of the ultrasonic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com