Powder coating gelation time tester

A gel time, powder coating technology, applied in the investigation phase/state change and other directions, can solve the problems affecting the measurement gel time accuracy, uncontrollable heating temperature, clean powder coating, etc., to increase practicality, disassembly and assembly. The effect of convenient maintenance and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

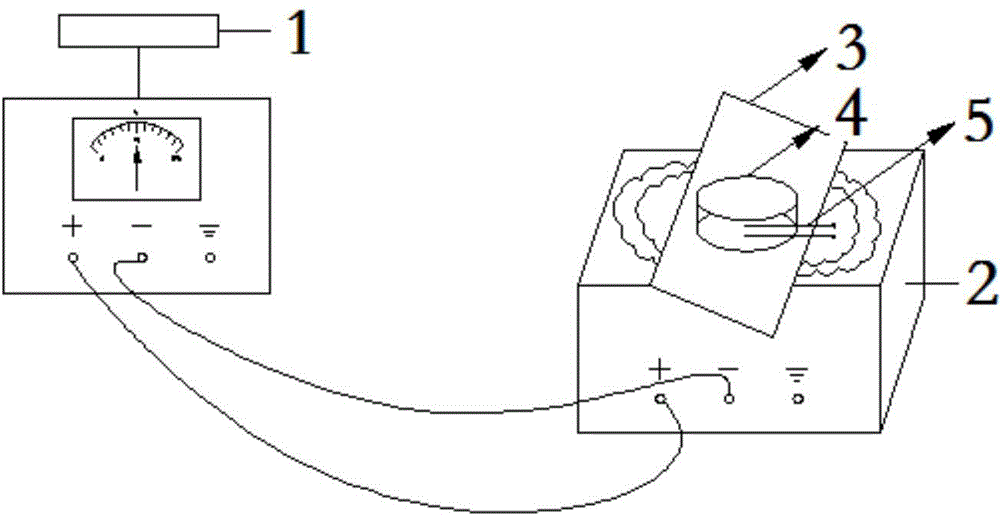

[0024] Such as figure 1 As shown, the technical solution of the present invention is a powder coating gelation time tester, the tester includes an adjustable heating device, a heat conduction device and a heating device, and the heat conduction device is arranged on the upper part of the adjustable heating device , the heating device is arranged on the upper part of the heat conduction device, and the heating device includes at least one horizontal outer surface. The adjustable heating device includes a power supply, an adjustable transformer 1 and an electric heating furnace 2, and the adjustable transformer 1 is connected to the electric heating furnace 2 through wires. The other end of the adjustable transformer 1 is connected to the power supply through wires, and the adjustable transformer 1 is provided with an adjustment knob. The heat conduction device is made of heat conduction material, the outline of the heat conduction device is a plane plate, and the heat conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com