Heating tool for heat shrinkage sealing cap for automobile wire harness

A heat-shrinkable sealing cap and heating tool technology, which can be applied to home appliances, other home appliances, applications, etc., can solve problems such as uneven heating, low heating efficiency, and easy heat deformation and burns of automobile wiring harnesses, so as to avoid heat deformation, The effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

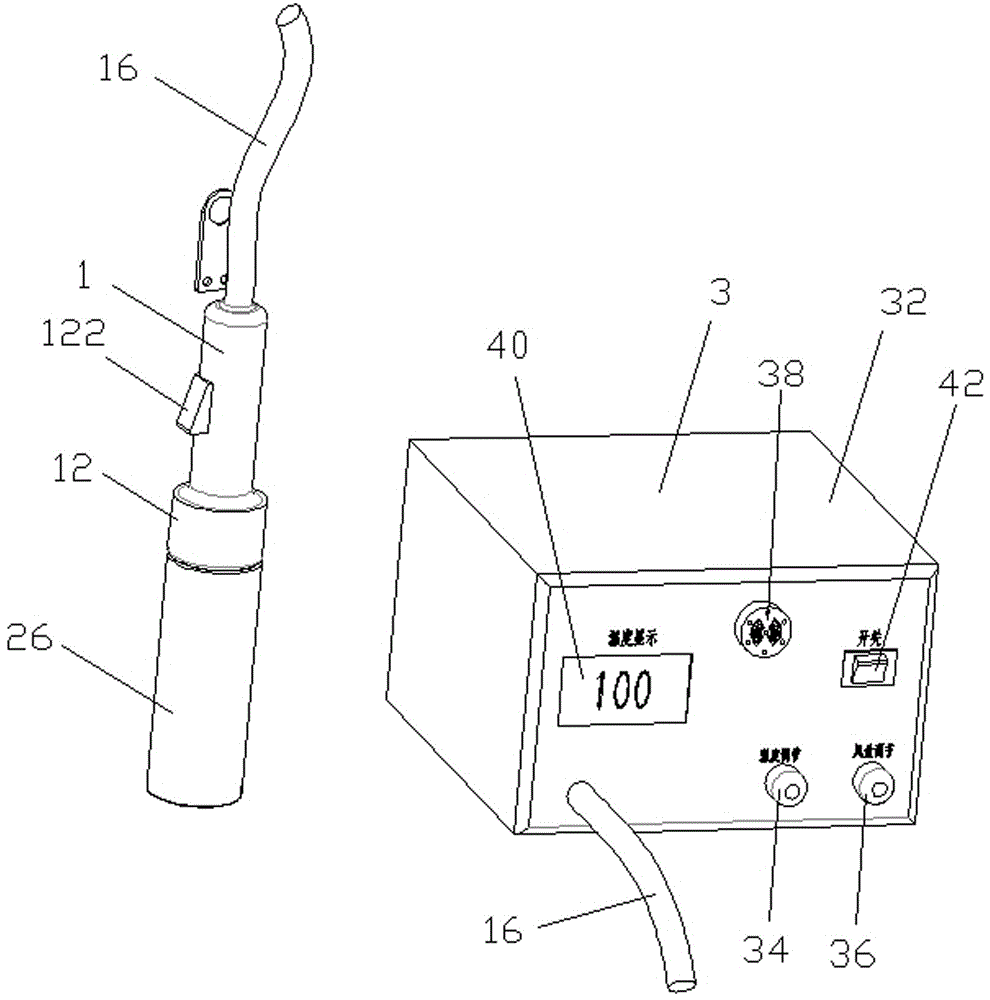

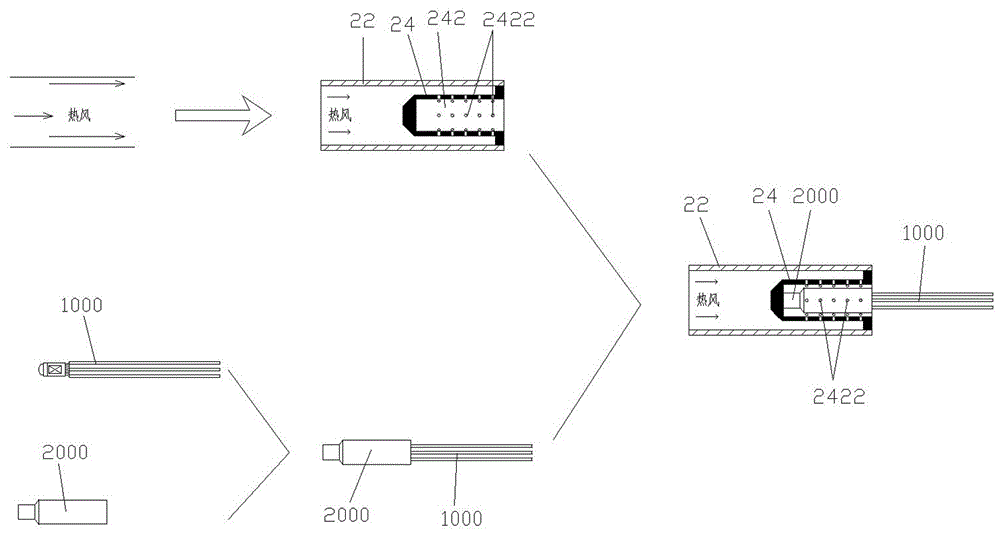

[0023] see Figure 1 to Figure 3 A heating tool for heat-shrinkable sealing caps for automobile wiring harnesses, comprising an operating handle 1 and an electric control box 3.

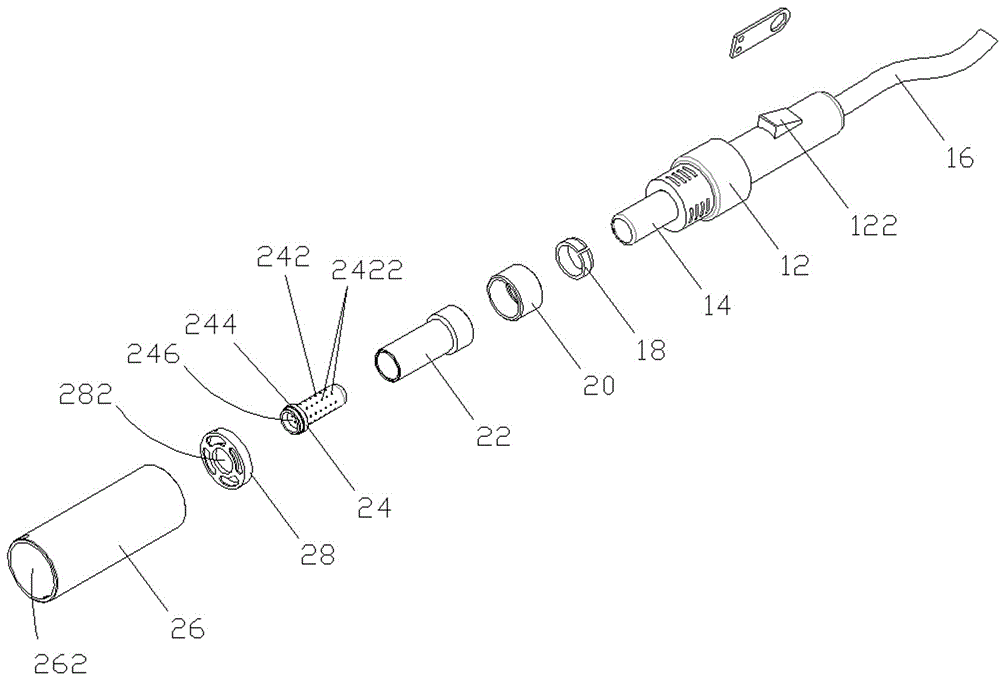

[0024] The operating handle 1 includes a handle body 12, a handle body mounting shell 14, a silicone tube 16, a small taper sleeve 18, a taper sleeve 20, an outer sleeve 22, a heat shrinkable mold 24, a protective cover 26, and a gland 28.

[0025] A timer switch 122 is installed on the handle body 12 .

[0026] The handle body installation shell 14 is installed on the front end of the handle body 12 .

[0027] One end of the silicone tube 16 is connected to the rear end of the handle body 12, and the other end is connected to the electric control box 3.

[0028] The small tapered sleeve 18 is sleeved on the outside of the handle mounting shell 14 .

[0029] The taper sleeve 20 is sleeved on the outside of the small taper sleeve 18 .

[0030] The rear end of the outer sleeve 22 is sleeved on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com