Powder coating gelation time tester

A technology of powder coating and gel time, which is applied in the investigation stage/state change, etc., can solve the problems that affect the measurement accuracy of gel time, clean the powder coating, and uncontrollable heating temperature, etc., so as to increase practicality and reduce heat The effect of draining and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

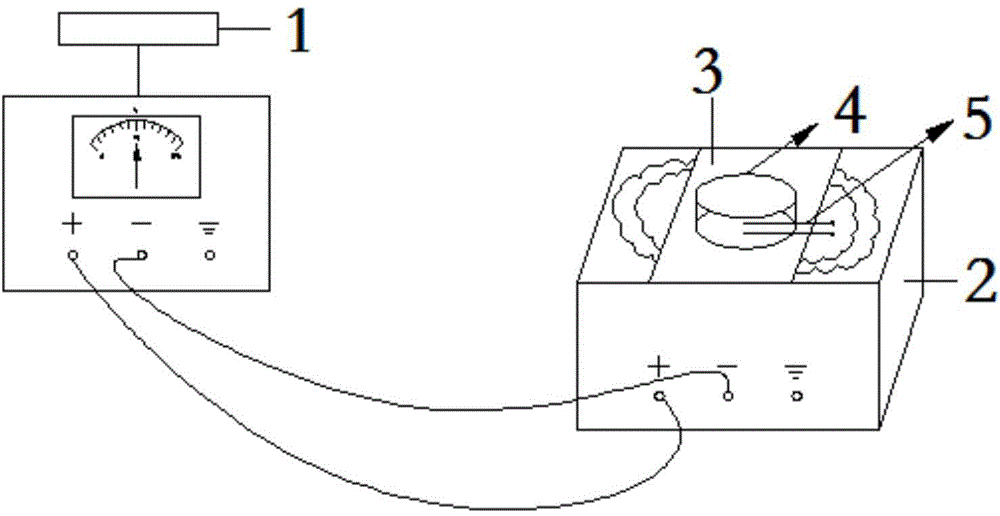

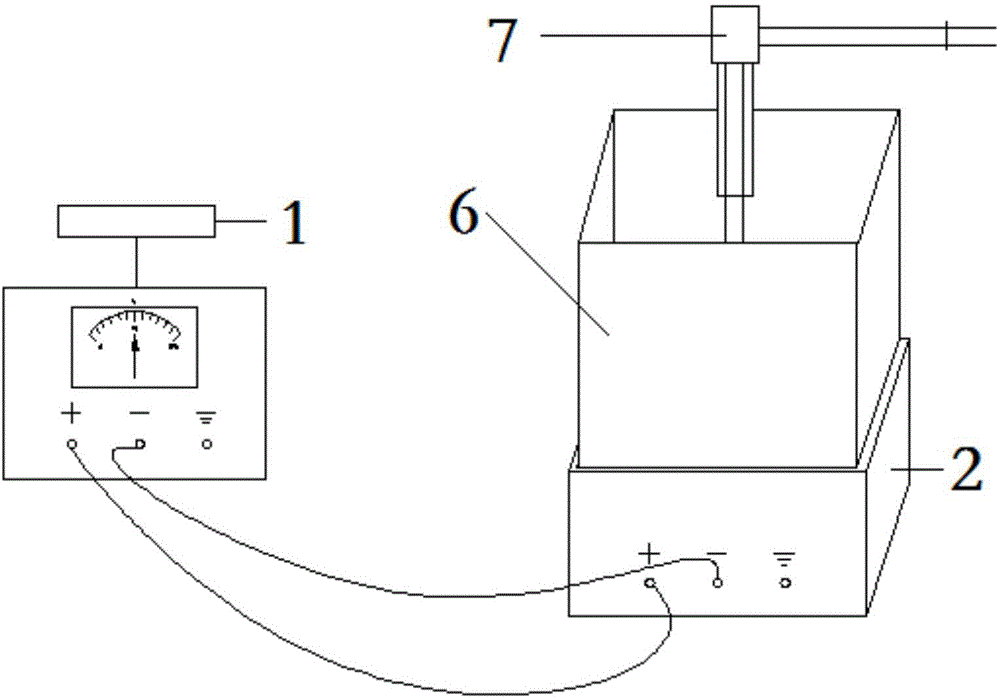

[0028] Such as figure 1 As shown, the technical solution of the present invention is, a powder coating gelation time tester capable of uniform heating, the tester includes an adjustable heating device, a heat conduction device, a uniform heating system, and the uniform heating system includes a heating device, Stirring device and semi-closed box body 6, described semi-closed box body 6 is arranged on the top of described adjustable heating device, and described heat conduction device and heating device are arranged on described semi-closed box body 6 inside; Said heating device at least Consists of a horizontal exterior surface. The bottom and surroundings of the semi-closed box 6 are closed, and the top is open. The stirring device is arranged on the upper part of the heating device, and enters the semi-closed box 6 from the open end at the top of the semi-closed box 6 . The stirring device includes a lifting device 7 and a rotating device, and the rotating device is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com