Construction method of virtual prototype of multi-axle heavy vehicle

A technology of heavy-duty vehicles and virtual prototyping, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as poor reusability of models and documents, inability to incorporate experience and knowledge, and low modeling efficiency, etc., to reduce individuality Reduce labor, improve modeling efficiency and model quality, and achieve explicit effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention is described in detail below with reference to accompanying drawing and embodiment:

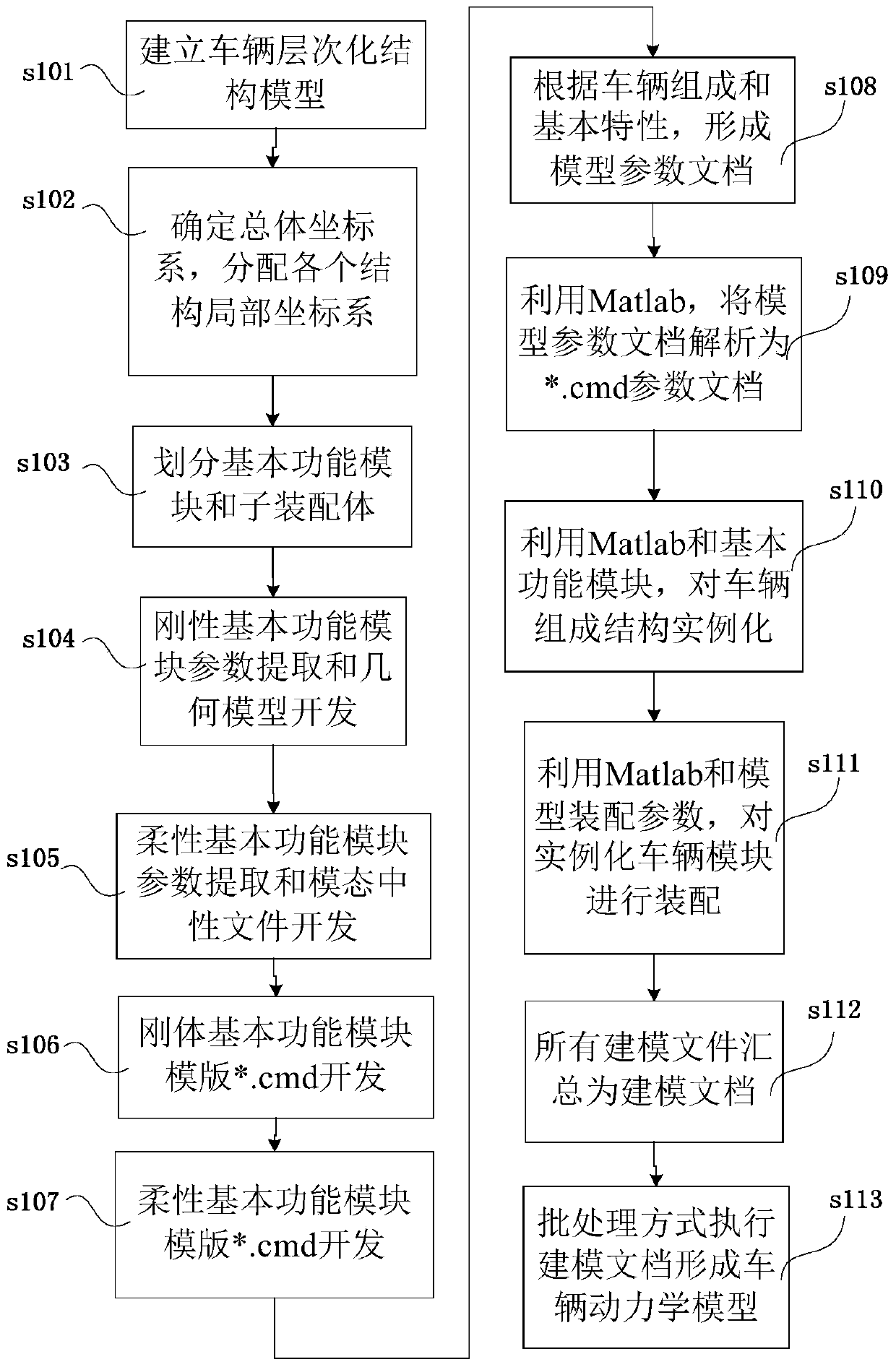

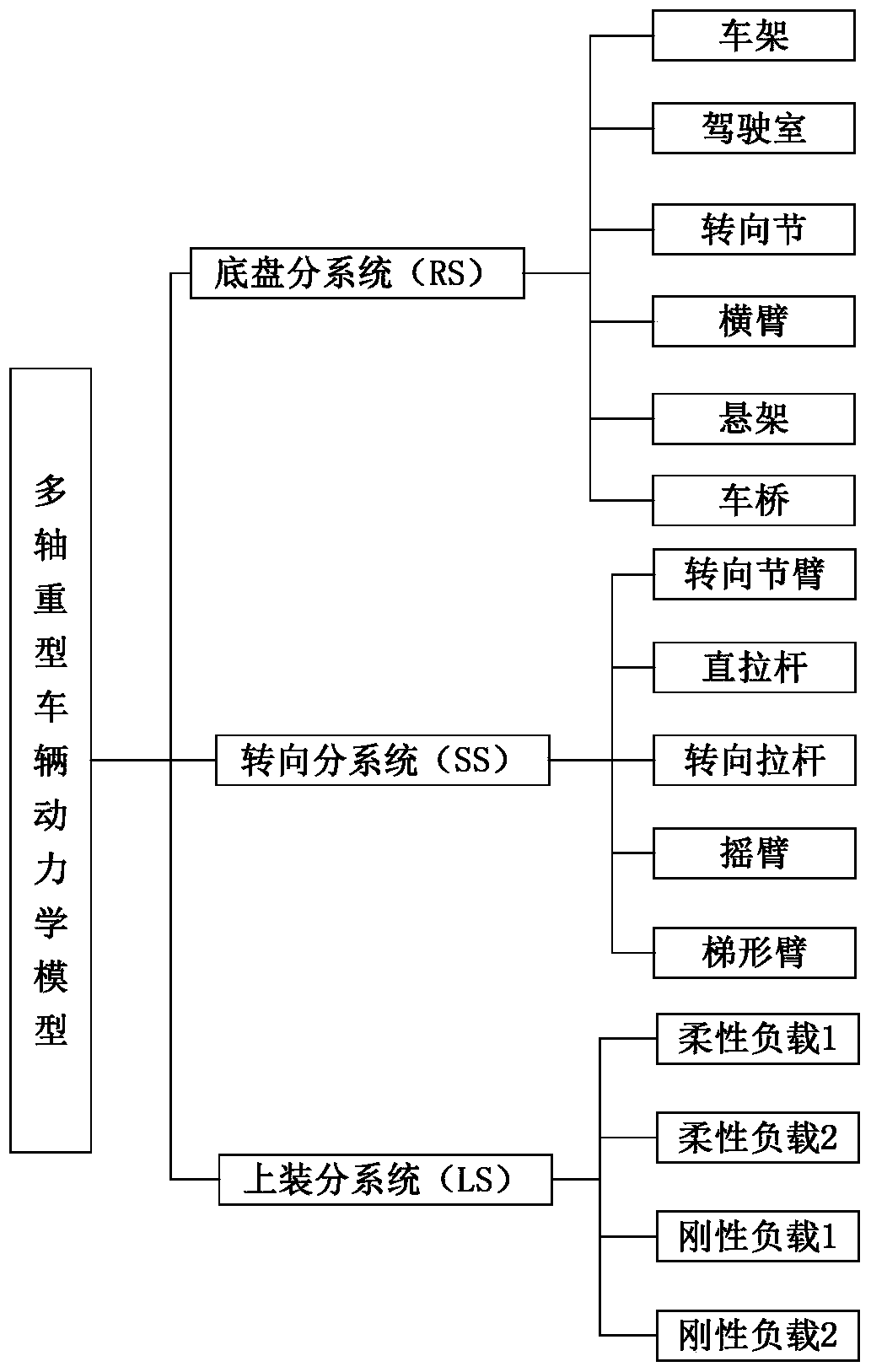

[0052] attached Figure 1-2 It can be seen that a method for constructing a virtual prototype of a multi-axle heavy vehicle comprises the following steps:

[0053] Such as figure 1 Schematic diagram of the process.

[0054]The flow starts at step s101, establishing a vehicle hierarchical structure model.

[0055] In step s102, the overall coordinate system is determined, and the local coordinate systems of each structure are assigned.

[0056] In step s103, sub-assemblies and basic functional modules are divided.

[0057] In step s104, parameters of rigid basic function modules are extracted and geometric models are developed.

[0058] In step s105, parameters of the flexible basic function module are extracted and a modal neutral file is developed.

[0059] In step s106, the rigid body basic function module template *.cmd is developed.

[0060] In step s10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com