Method for encapsulating LED device with metal substrate

A technology for LED devices and metal substrates, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of metal substrate deformation, metal substrate residue, etc., and achieve the effect of improving quality, avoiding the possibility of damage, and simple process implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

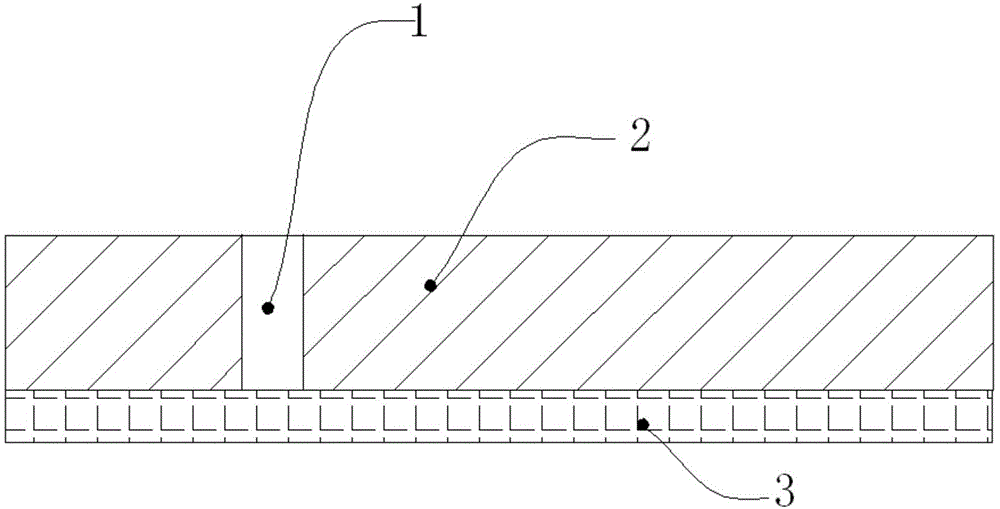

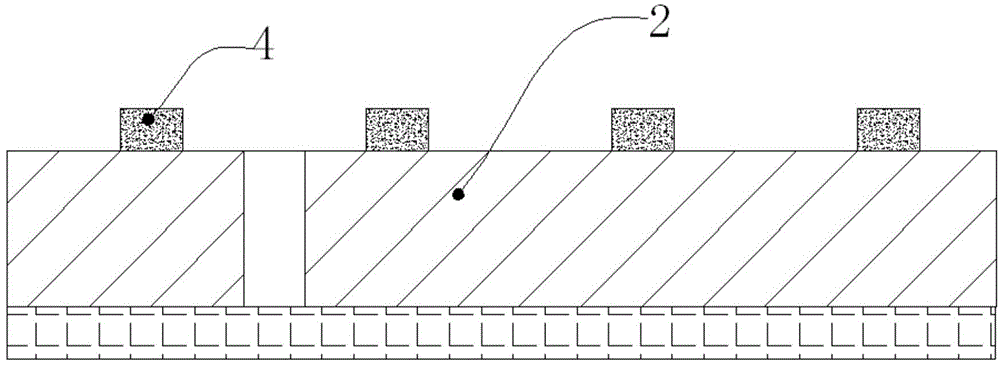

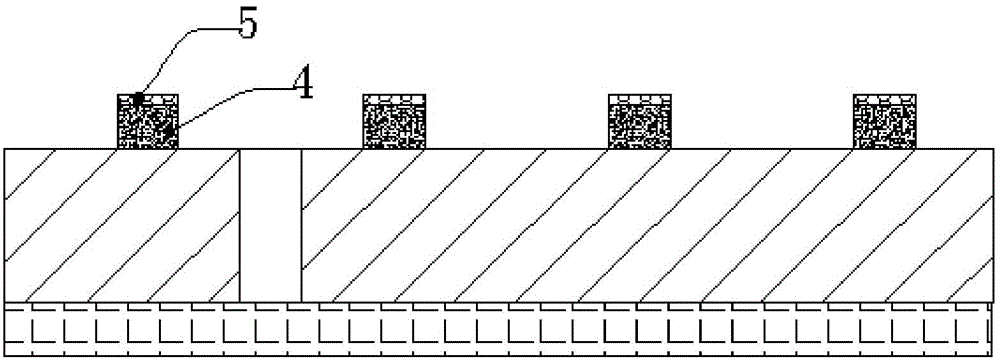

[0040] The invention proposes a LED device packaging method with a metal substrate, the metal substrate is a hollow substrate, including: a film, a layer of film is pasted on the back of the metal substrate; crystal bonding, the LED chip is fixed on the metal substrate and bonded. wires to form a circuit; making a fluorescent layer, making a fluorescent layer on the LED chip; encapsulating, making a packaging layer on the LED chip to package the LED chip; removing the film, removing the film; slicing, cutting the metal substrate, so that each The LED chips form individual units.

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] Embodiment 1 of the LED device packaging method with a metal substrate of the present invention can be found in Figure 1 to Figure 6 shown.

[0043] The metal substrate 2 is a silver-plated copper sheet, which is a hollow substrate, and the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com