A new repair method for steel epoxy sleeve

A technology of epoxy sleeve and new method, which is applied in the field of steel epoxy sleeve repair and repair of large-diameter pipelines. It can solve the problems of brittle cracking of epoxy resin, damage of steel epoxy sleeve, bending resistance, and Impact performance and other issues, to achieve the effect of easy realization, convenient operation, improved bending resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

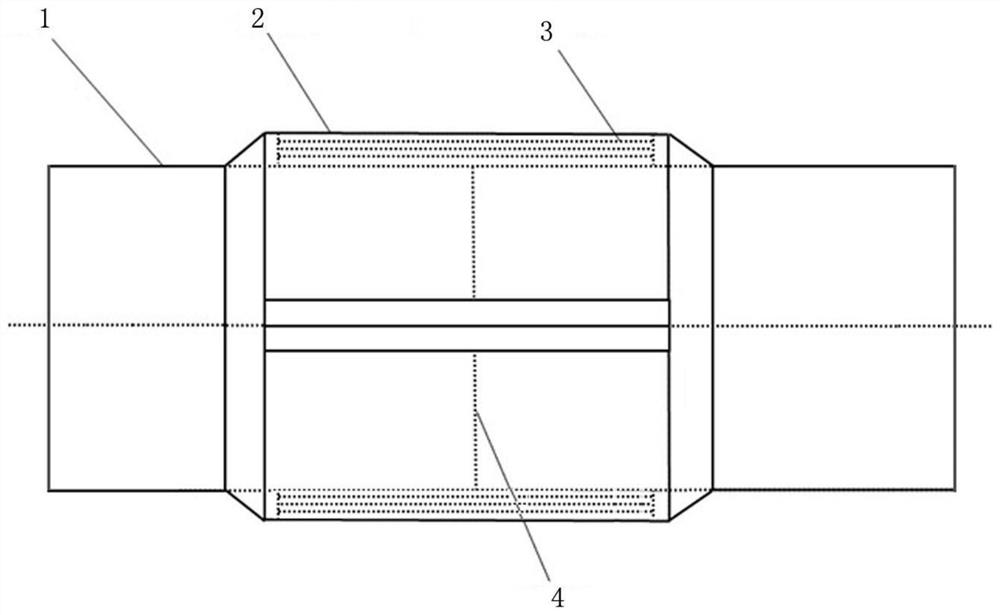

[0034] refer to figure 1 and figure 2 , the steel epoxy sleeve repair method provided by the present invention comprises the following steps:

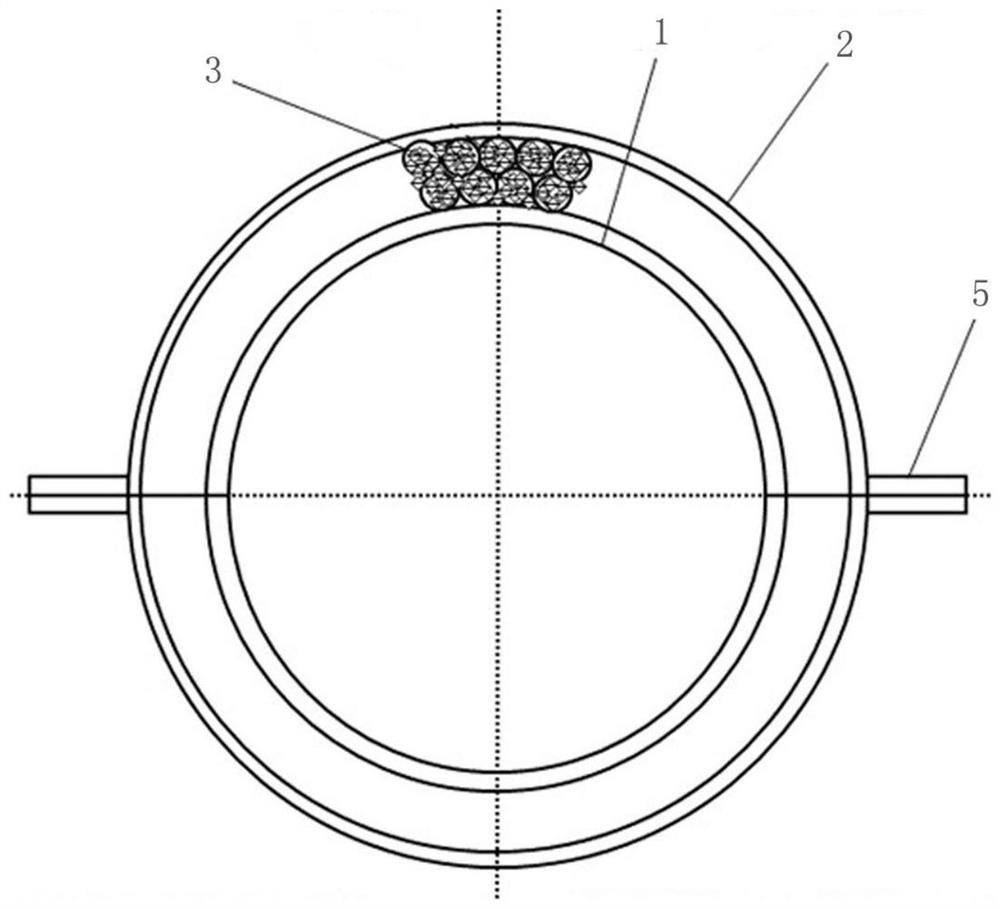

[0035] Step1: Make epoxy particle tube

[0036] Pour the epoxy resin into the thin-walled steel pipe and let it stand for 24 hours to solidify the epoxy resin to form the epoxy particle tube 3 .

[0037] The length of the thin-walled steel pipe is slightly shorter than the length of the sleeve 2, and the pipe diameter is 50-60mm.

[0038] Step2: Make the sleeve with chamfer

[0039] Chamfers are made on both ends of the ordinary sleeve, and the slope ratio of the chamfer is 1:2 to form a sleeve 2 with chamfers.

[0040] The wall thickness of the sleeve 2 is determined according to the wall thickness of the pipe body 1 to be repaired, and is generally 3 / 4-1 times of the wall thickness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com