An explosion-proof battery pack

A battery pack, explosion-proof technology, applied in battery pack parts, batteries, secondary battery repair/maintenance, etc., can solve the problems of surrounding single battery fire, potential safety hazards, poor fire performance, etc., to prevent the spread of fire The effect of increasing fire and explosion-proof performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

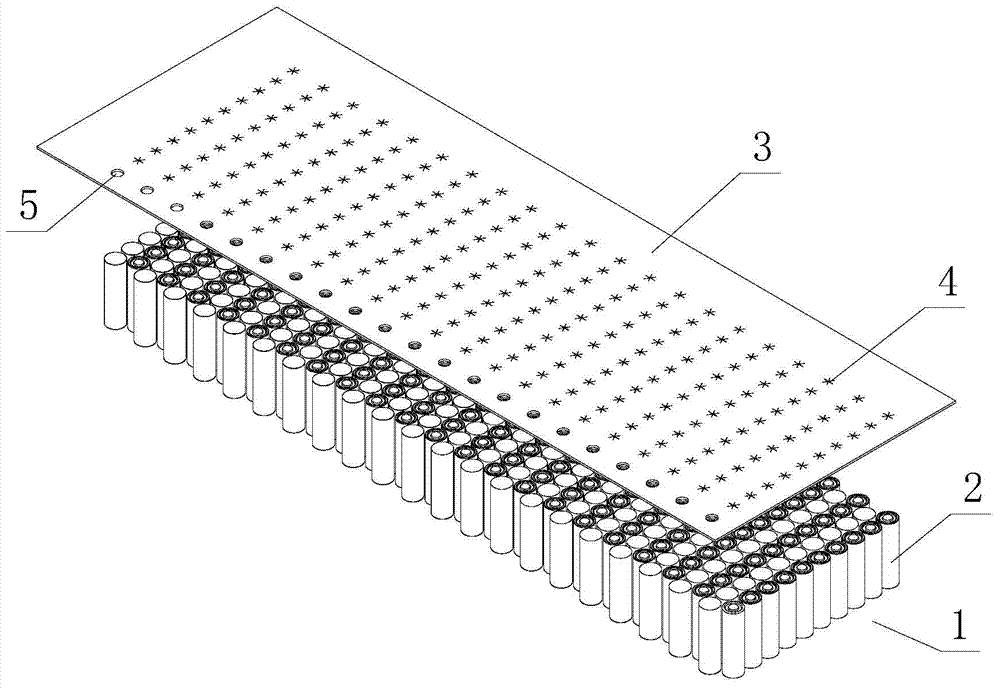

[0014] Such as figure 1 and figure 2 An explosion-proof battery pack is shown, a kind of explosion-proof battery pack, including a battery pack 1 formed by multiple rows and rows of single cells 2, the battery pack 1 is covered with a fireproof mat 3, and the fireproof The pad 3 is provided with a fire discharge gap 4 and a total fire discharge hole 5. The fire discharge gap 4 is arranged in multiple rows and rows, and the fire discharge gap 4 is located directly above the positive pole of the single battery 2. The total fire discharge hole 5 is located at one side end of every row of fire-discharging gap 4.

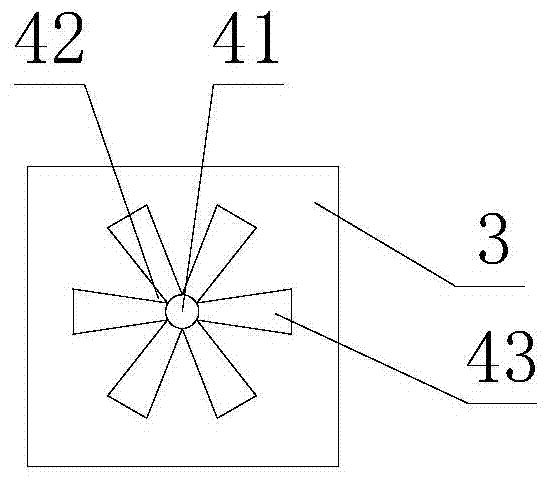

[0015] The fire discharge gap 4 includes a soft column 41, a tip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com