Moulded case circuit breaker mounting seat

A molded case circuit breaker and mounting seat technology, which is applied in the direction of circuits, emergency protection devices, busbars/circuits, etc., can solve problems such as unfavorable disassembly and assembly, and achieve the effects of improving production efficiency, reducing production costs, and strong scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

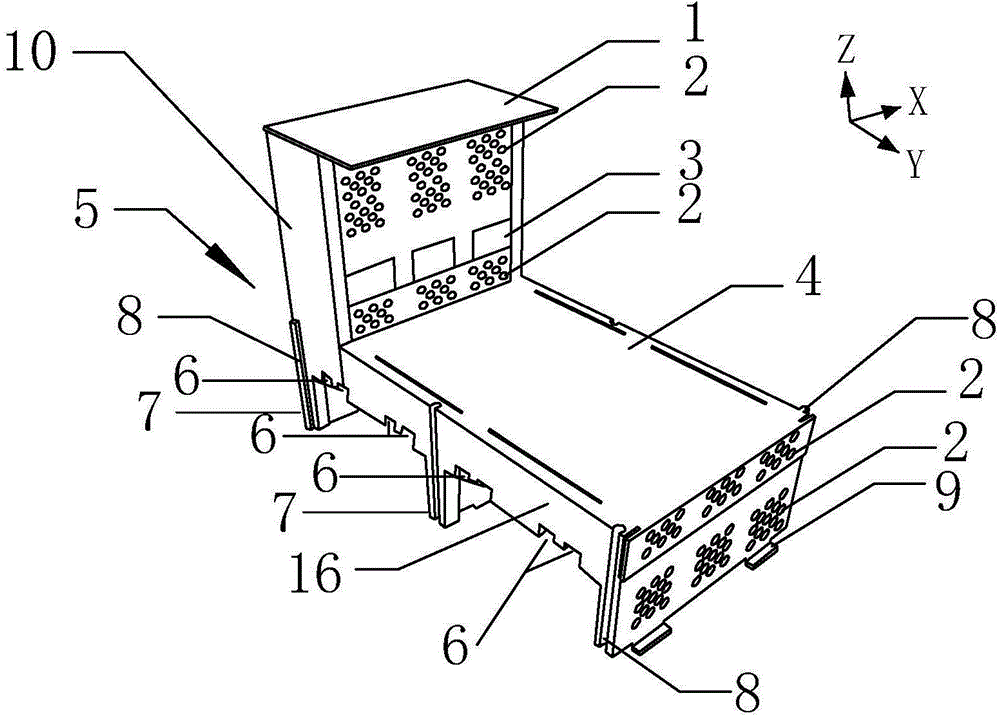

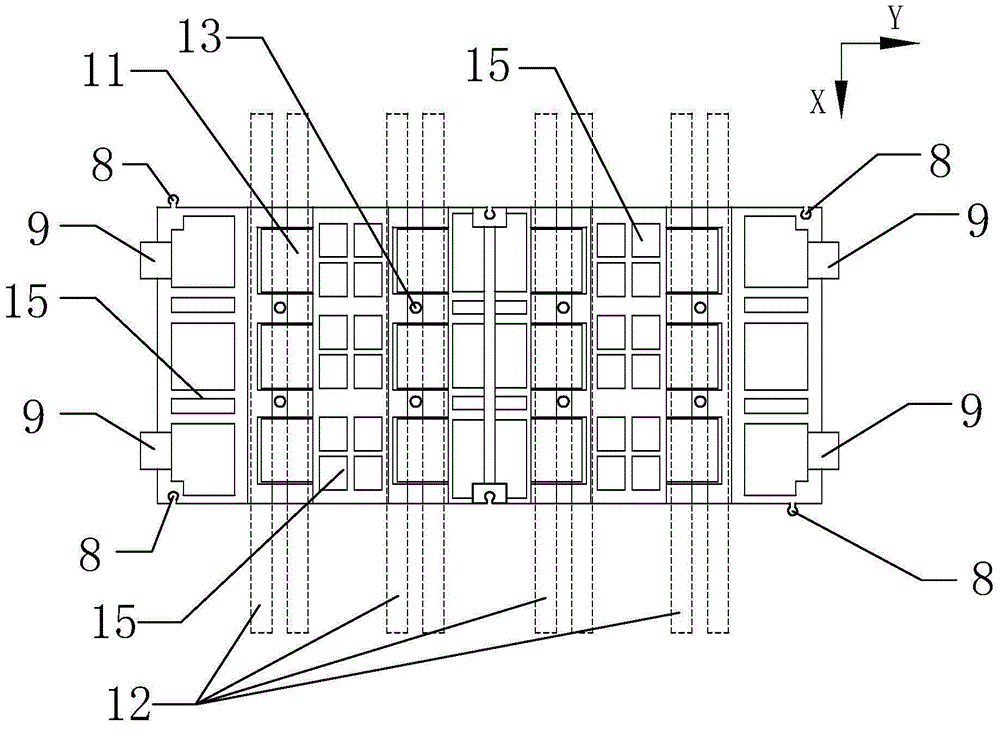

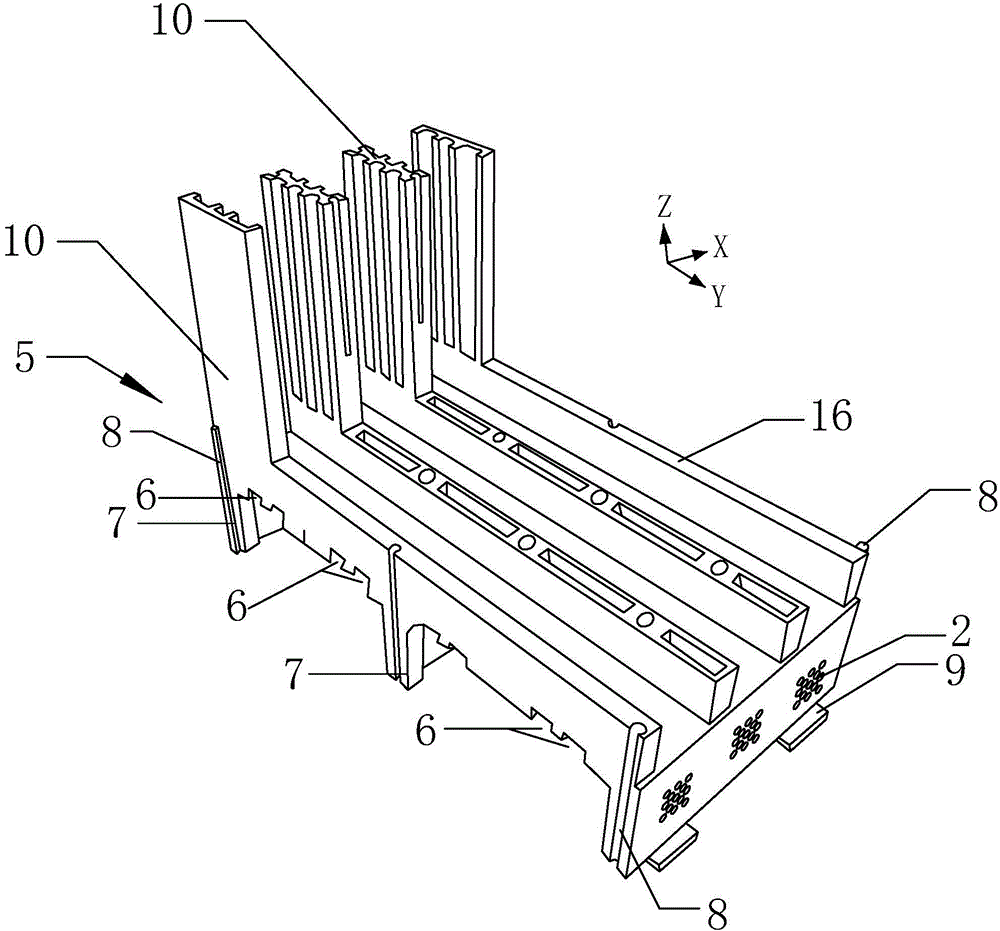

[0032] Embodiment 1, with reference to Figure 1 to Figure 5 , a molded case circuit breaker mounting base of the present invention includes the following structure:

[0033] The mounting seat 5 includes a mounting partition 16 along the Y-axis direction, and a safety partition 10 along the Z-axis direction. The bottom of the installation partition 16 extends downward with a support member 7, and the bottom of the installation partition 16 is provided with four sets of copper row installation grooves 6 along the X-axis direction, each group of two copper row installation grooves 6, so The copper bar installation groove 6 is provided with a copper bar fixing installation hole 13, and generally two main mother copper bars 12 are placed side by side in the copper bar installation groove 6, and are fixed through the copper bar fixing installation holes 13. The copper bar mounting groove is also provided with a semi-closed branch copper bar power-taking hole 11, and the plastic sh...

Embodiment 2

[0037] Embodiment 2, with reference to Figure 6 to Figure 9 , the mounting seat 5 is an inverted "T"-shaped structure, the safety partition 10 is set in the middle of the mounting seat 5, and two branch copper bar safety baffles 4 are inserted from the front end and the rear end of the mounting seat 5 respectively. Installed on the mounting base 5, the length of the front plate of the corresponding outlet terminal safety baffle 1 is equal to the length of the rear panel, and the lower ends of the front panel and the rear panel are all provided with outlet holes 3 for the outlet terminals. A reinforcing rib 14 is provided at the angle between the upper baffle and the middle baffle of the branch copper bar safety baffle 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com