A high and low voltage ride through cooperative control method for doubly-fed wind turbines

A doubly-fed wind turbine, high-low voltage ride-through technology, applied in motor generator control, electronic commutation motor control, wind power generation, etc., can solve problems such as failure to consider the contribution of the unit to the faulty grid and difficulty in achieving high-voltage ride-through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawings and examples of implementation.

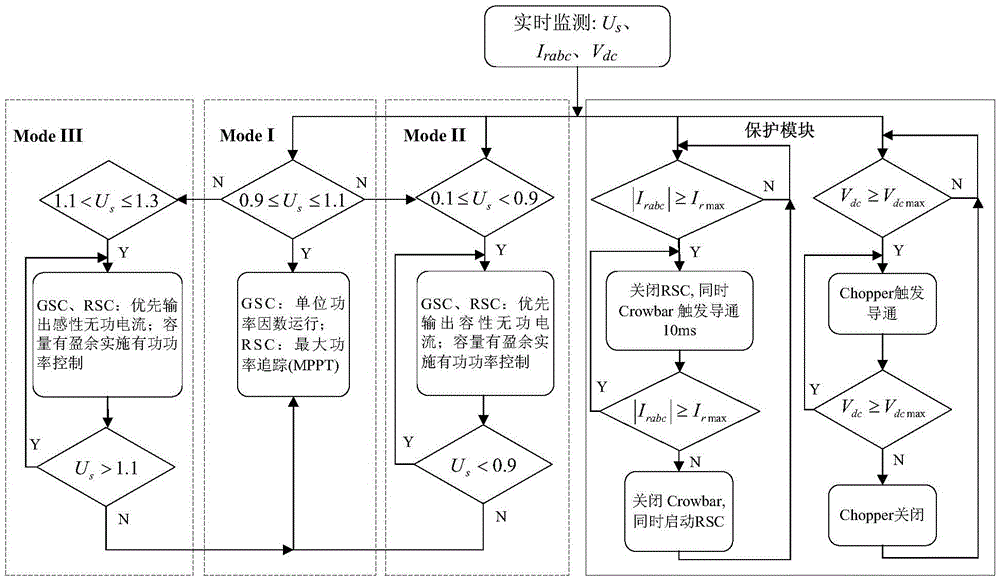

[0026] figure 1 Represent the control flow chart of the high and low voltage ride-through cooperative control method of the doubly-fed wind turbine set of the present invention, refer to figure 1 , a high and low voltage ride through coordinated control method for a doubly-fed wind turbine described in the present invention includes:

[0027] 1. According to the real-time monitoring of the doubly-fed wind generator (DFIG) stator terminal voltage U s Level (rated value is 1pu), the operating state of the doubly-fed wind turbine is divided into normal operating mode (marked as ModeI), low-voltage ride-through operating mode (marked as ModeII), high-voltage ride-through operating mode (marked as ModeIII), etc. 3 operating modes; specifically:

[0028] 1.1 When 0.9pu≤U sWhen ≤1.1pu, the doubly-fed wind turbine is in the normal operation mode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com