flavor improver

A technology of flavor and gelatin hydrolyzate, which is applied in the field of flavor improvers, can solve problems such as no records, and achieve excellent flavor improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

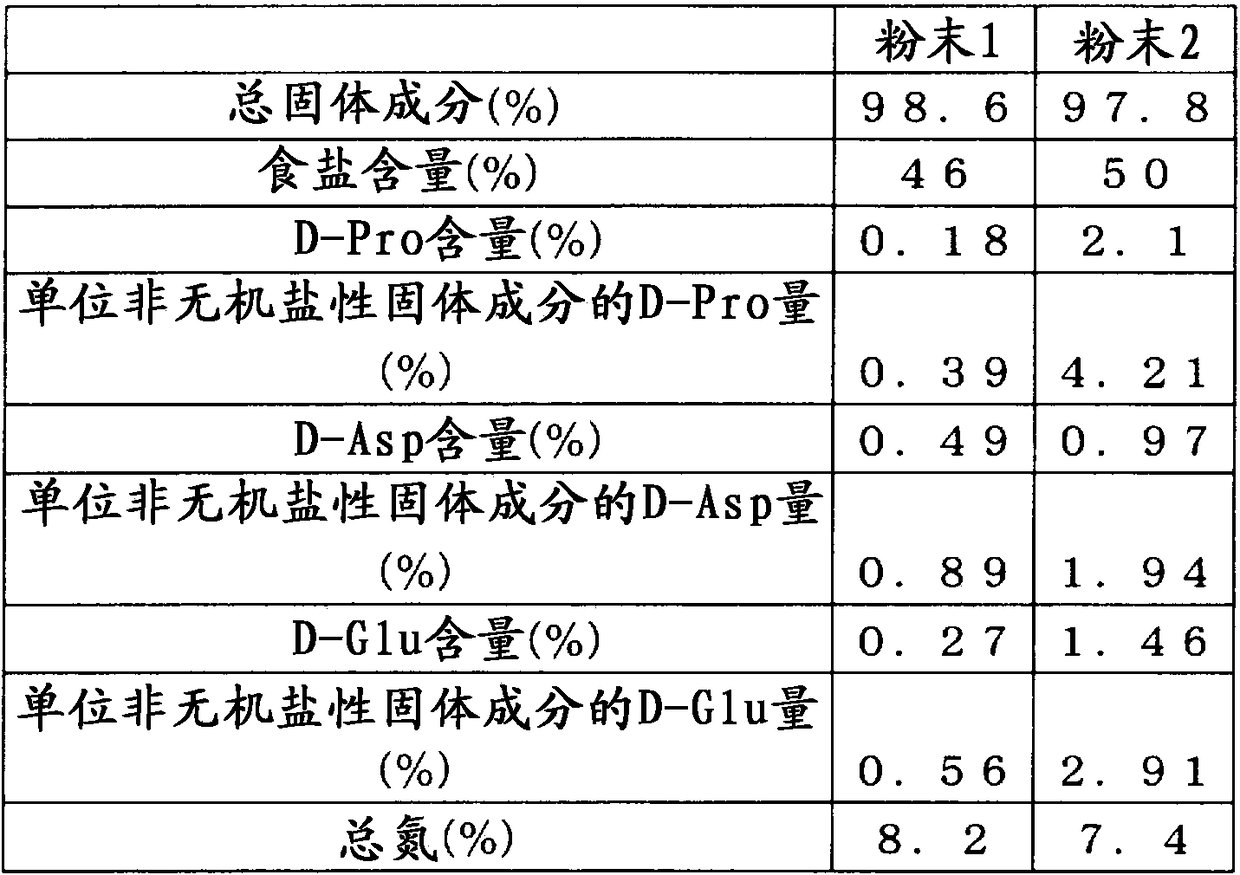

[0076] 60 mL of 10 mol / L hydrochloric acid and 28 g of gelatin (87.5% loss on drying) were mixed in a storage bottle to prepare a test solution. Next, using a pressurized container, stirring heat treatment was performed at 125°C for 18 hours (test solution 1) and 72 hours (test solution 2). After cooling the test solution, it was adjusted to pH 4 using an aqueous sodium hydroxide solution. The pH-adjusted test liquids 1 and 2 were dried with hot air so that the water content became 5% by mass or less, and respective powders 1 and 2 were obtained. Table 2 shows the results obtained by analyzing the obtained powder. The amount of D-proline per unit of non-inorganic salt (salt) solid content is the value obtained by excluding inorganic salt (salt) from the total solid content, and the D-proline measured by GC (detector is FID) is used. -The mass ratio of the amount of proline is used for quantification. The total nitrogen is represented by mass % per unit total mass (by Kjelda...

Embodiment 2

[0080] Example 2: Curry Sauce (1)

[0081] 100 g of commercially available curry paste was mixed with 700 mL of warm water to obtain curry sauce.

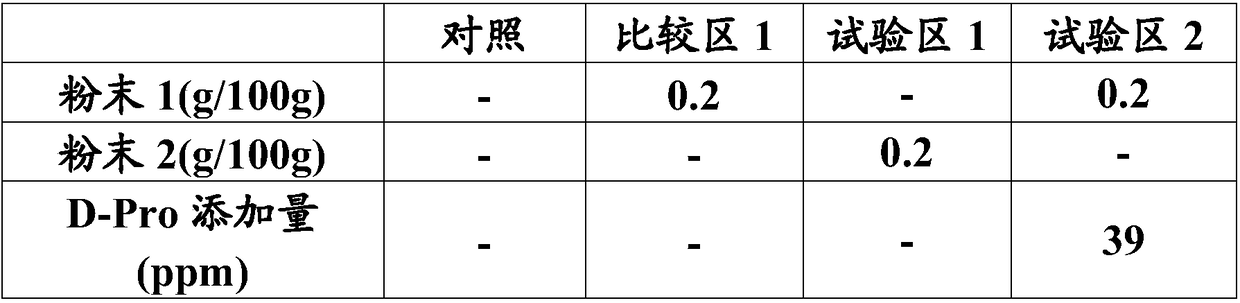

[0082] 100 g of the above-mentioned curry sauce was dispensed into the bag, and using the powders 1 and 2 obtained in Example 1, the curry sauces of the test areas 1 and 2 were prepared according to the combination in Table 2.

[0083] [Table 2]

[0084]

[0085] Calculated from the inorganic salt (salt) content of powders 1 and 2, and adjusted so that the concentrations of the inorganic salt (salt) in each zone were equal.

[0086] Powder (g / 100g) shows the addition amount with respect to 100 g of curry sauces.

[0087] ppm=mass / mass (the amount of D-proline added to 100 g of curry sauce)

[0088]Each of the prepared bags was sealed with a sealing machine, and heated for 10 minutes in the state of the sealed bags in a boiling bath.

[0089] After heating, the flavor and the like of the contents of the pouch were compared wi...

Embodiment 3

[0102] Example 3: Curry Sauce (2)

[0103] 100 g of commercially available curry paste was mixed with 700 mL of warm water to obtain curry sauce.

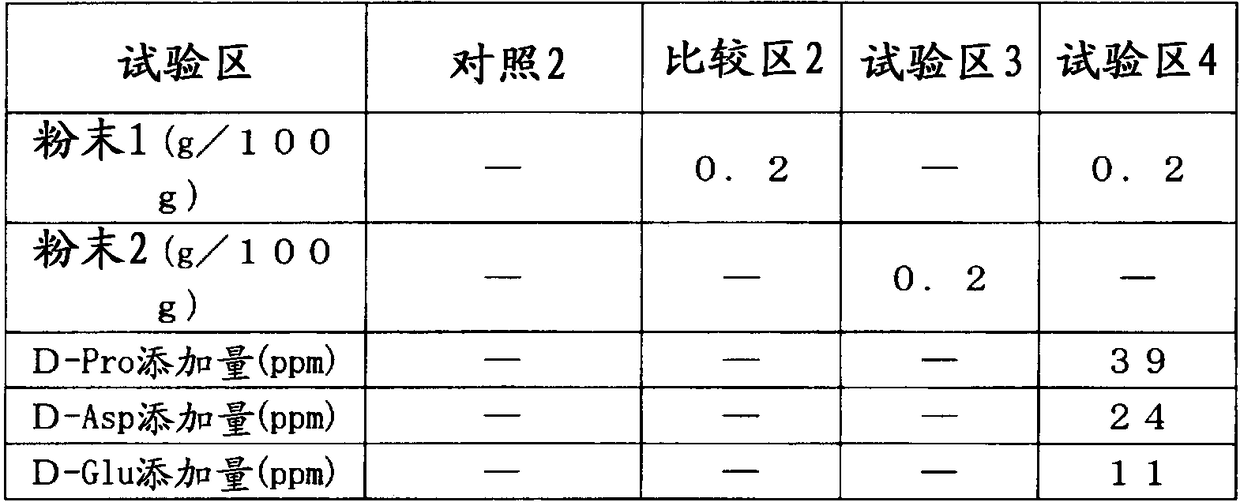

[0104] The above-mentioned curry sauce was dispensed into bags at a time of 100 g, and the powders 1 and 2 obtained in Example 1 were used to prepare each test area according to the combination in Table 4.

[0105] [Table 4]

[0106] Table 4

[0107]

[0108] Calculated from the inorganic salt (salt) content of powders 1 and 2, and adjusted so that the concentrations of the inorganic salt (salt) in each zone were equal.

[0109] Powder (g / 100g) shows the addition amount with respect to 100 g of curry sauces.

[0110] ppm=mass / mass (addition amount of each D-amino acid relative to 100 g of curry sauce)

[0111] The prepared bag was sealed with a sealing machine, and heated for 10 minutes in the sealed bag state in a boiling bath.

[0112] After heating, the flavor of the contents of each bag was compared with the control, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com