Vibrating straw walker separation test stand with adjustable parameters

A separate test and draft-by-draft technology, applied in the field of test platforms, can solve the problems of small draft-by-draft load and loss, and achieve the effect of rational structure optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

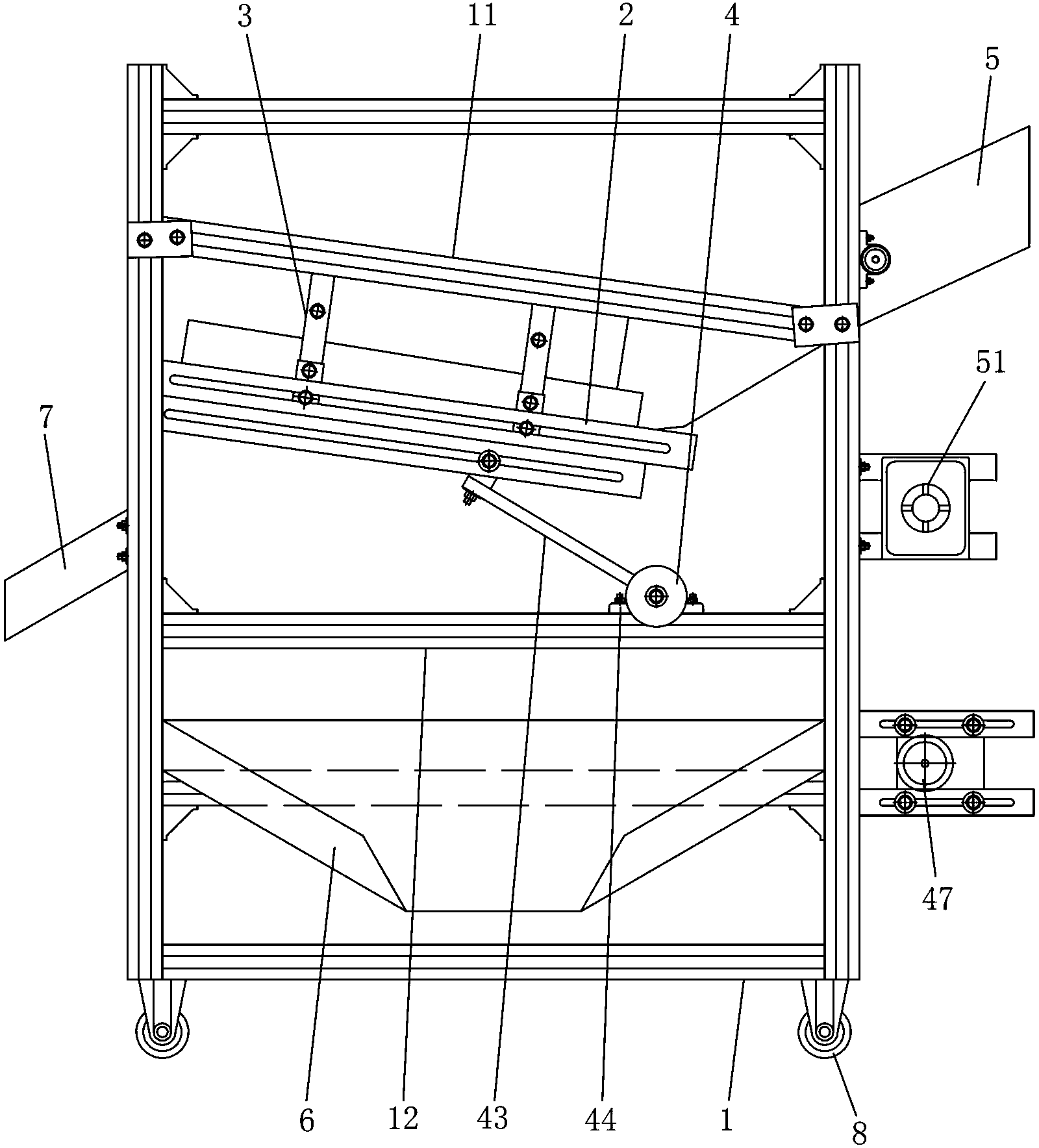

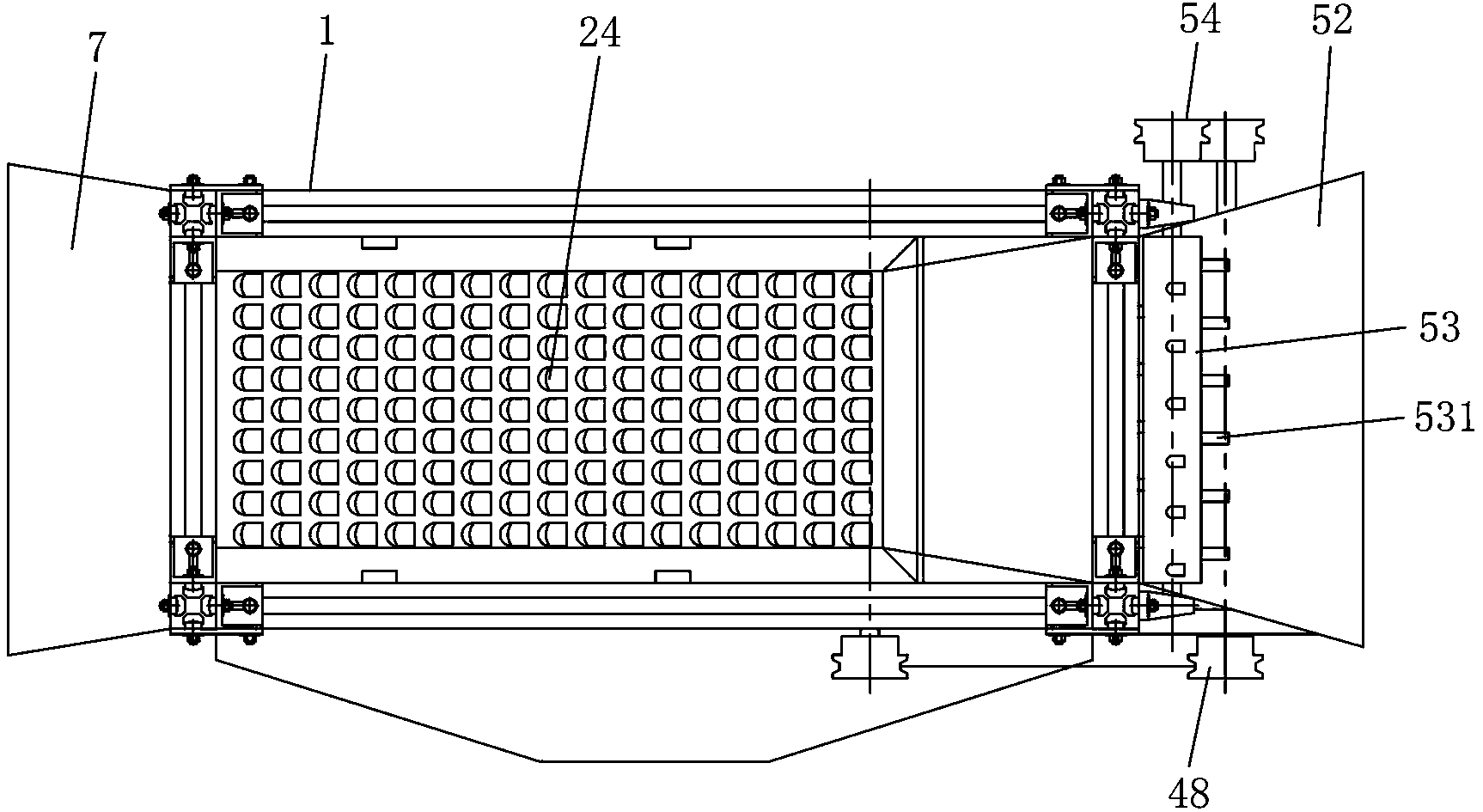

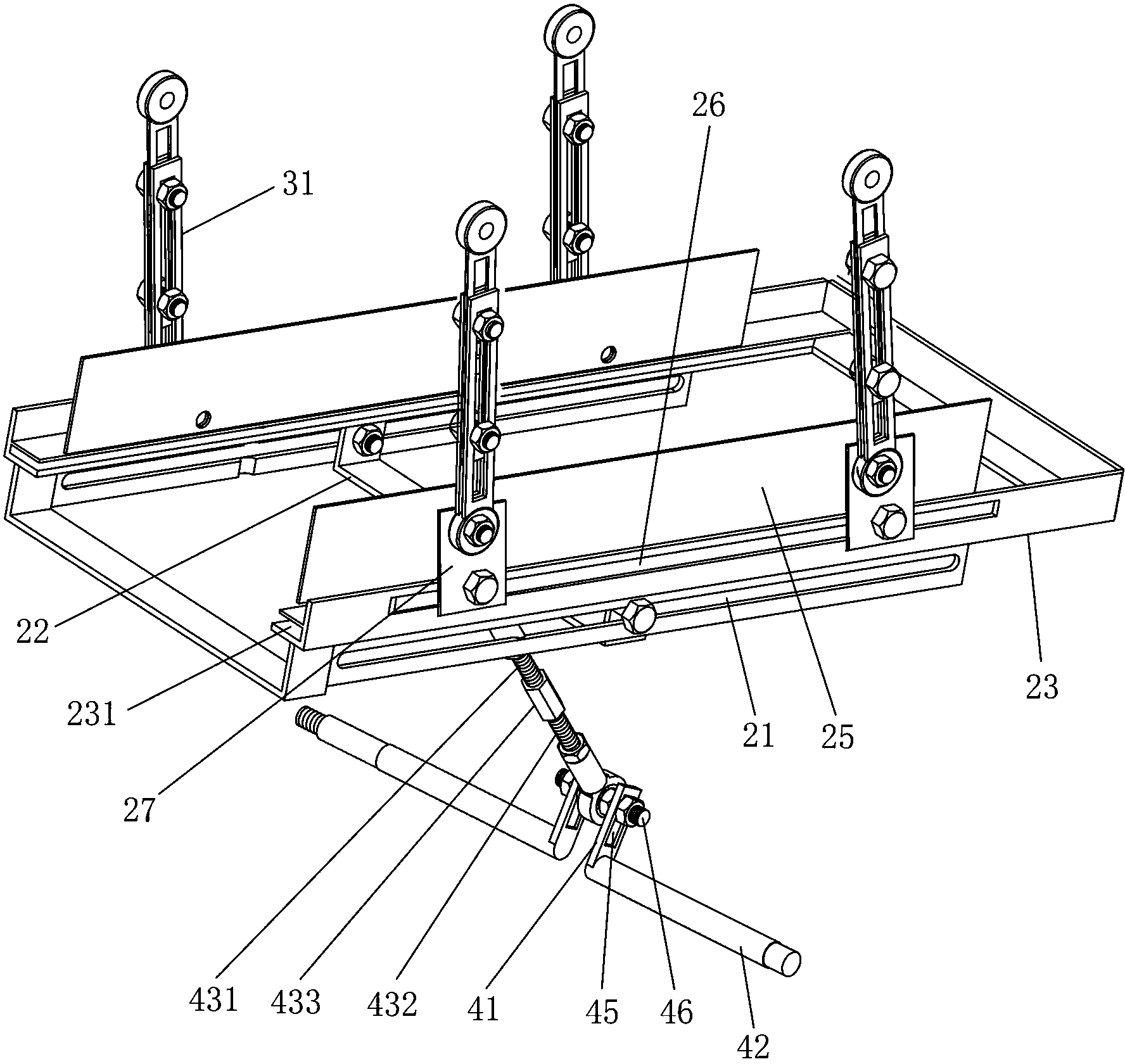

[0024] Such as Figure 1 to Figure 5 As shown, the parameter-adjustable vibration-by-draft separation test bench of the present invention includes a frame 1, a vibrating screen 2 installed on the frame 1 in an oblique shape through a pendulum mechanism 3, and a drive for driving the vibrating screen 2 to reciprocate and swing. Device 4, the driving device 4 includes a crank 41, a rotating shaft 42, a length-adjustable connecting rod 43, and a rotary drive assembly installed on the frame 1 for driving the rotating shaft 42 to rotate. The rotating shaft 42 is installed on the vibrating screen 2 through a bearing seat 44. On the frame 1 below, crank 41 links to each other with rotating shaft 42, and crank 41 is provided with a first connecting mechanism that the installation distance to crank 41 rotation centers can be adjusted, and one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com