Lens structure group for researching actions of physical experimental lens on light

A technology of physical experiment and lens structure, applied in educational appliances, instruments, teaching models, etc., can solve problems such as troublesome operation, poor functionality, and single effect, and achieve the effect of improving practicability, improving functionality, and applying hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

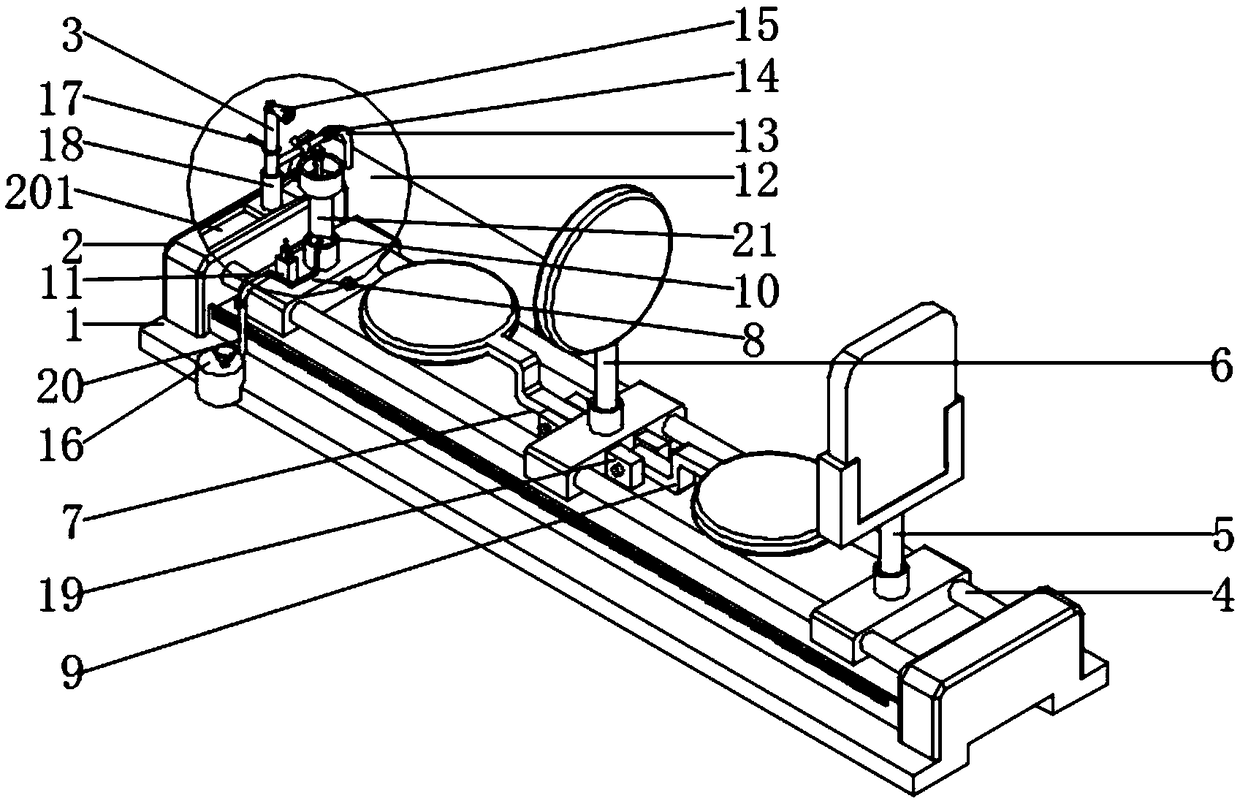

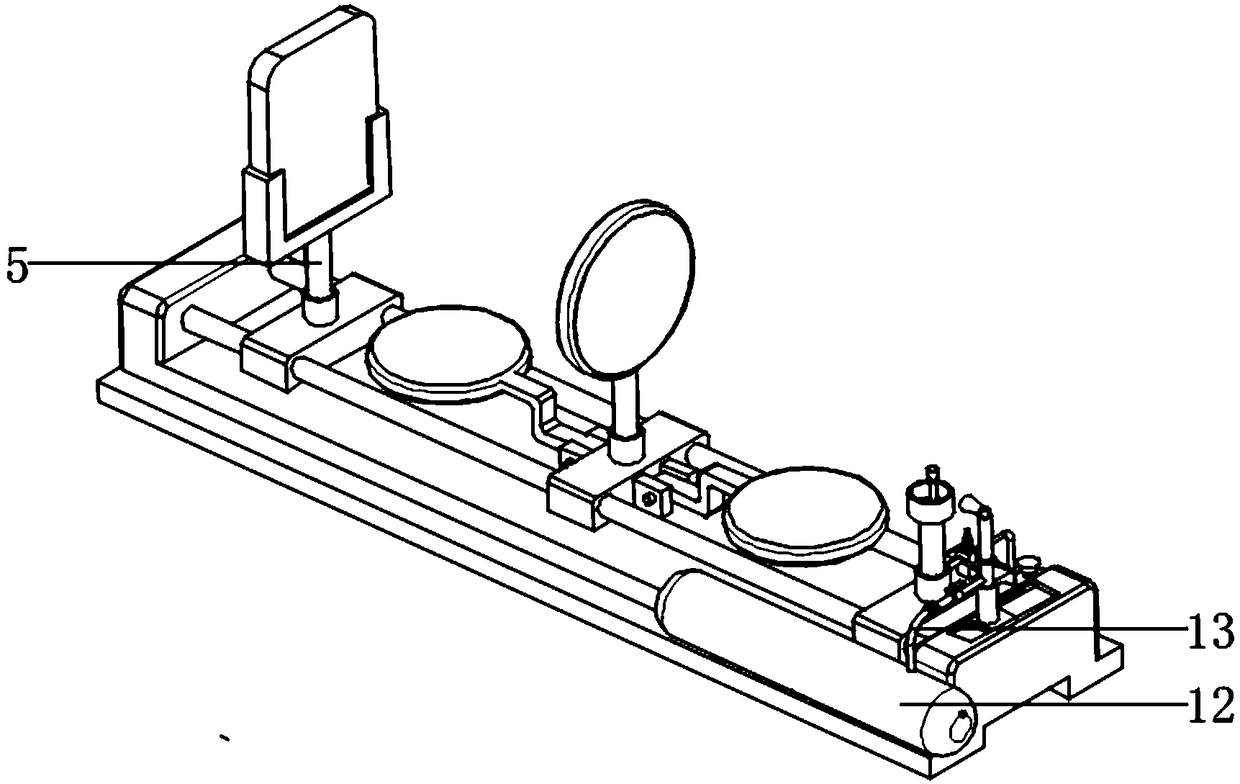

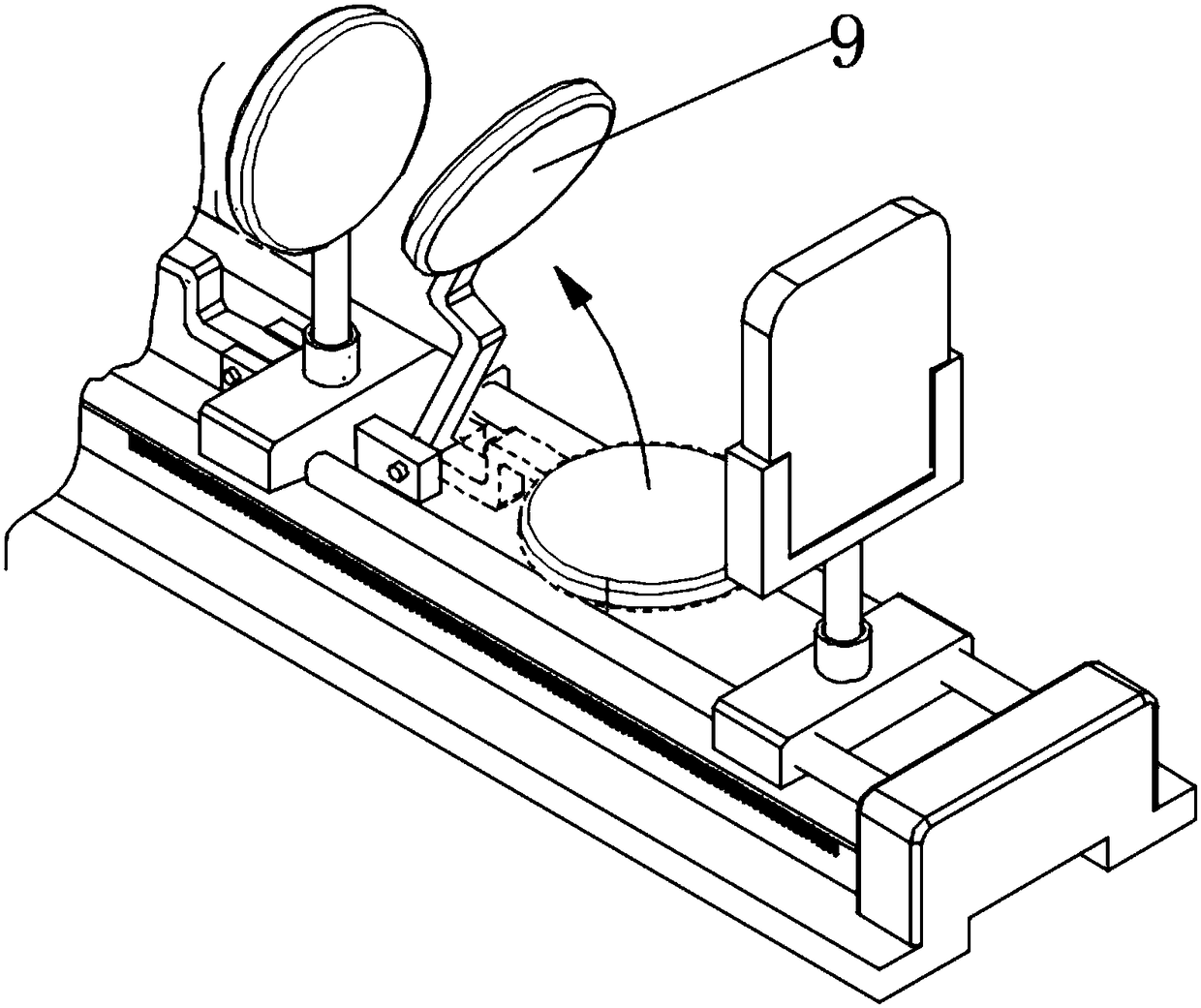

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The invention provides a lens structure group for studying the effect of a physical experiment lens on light, including a base plate 1, left and right columns 2, chute 201, an air blowing seat 3, a sliding tube 4, an image seat 5, a middle lens frame 6, and a left lens frame 7. Lamp holder 8, right lens holder 9, electronic ignition rod 10, electronic ignition frame 11, first gas tank 12, first gas outlet pipe 13, corrugated section 14, gas outlet head 15, second gas tank 16, trigger Rod 17, shaft sleeve 18, slider 1801, connecting lug 19, second air outlet pipe 20, ignition seat 21, connecting sleeve 22, object clamping frame 23 and clip 2301; the top surface of the bottom plate 1 passes through the left and right uprights 2 The way of running through the two sliding tubes 4 is slidingly fitted with an image holder 5, an intermediate lens holder 6 and a lamp holder 8, wherein the left and right end faces of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com