Automatic wagon oil paint marking position positioning device

A railway freight car, automatic positioning technology, applied in the direction of the injection device, etc., can solve the problems of missing marks, manual marking, etc., and achieve the effects of simple structure, convenient and simple adjustment, and saving manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

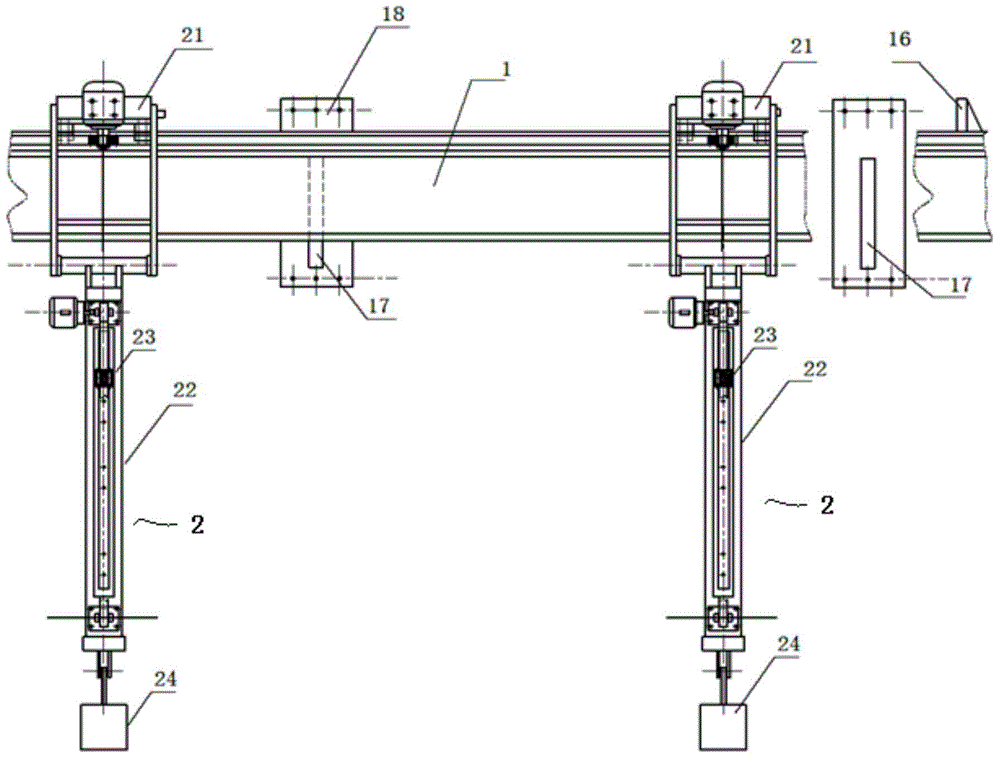

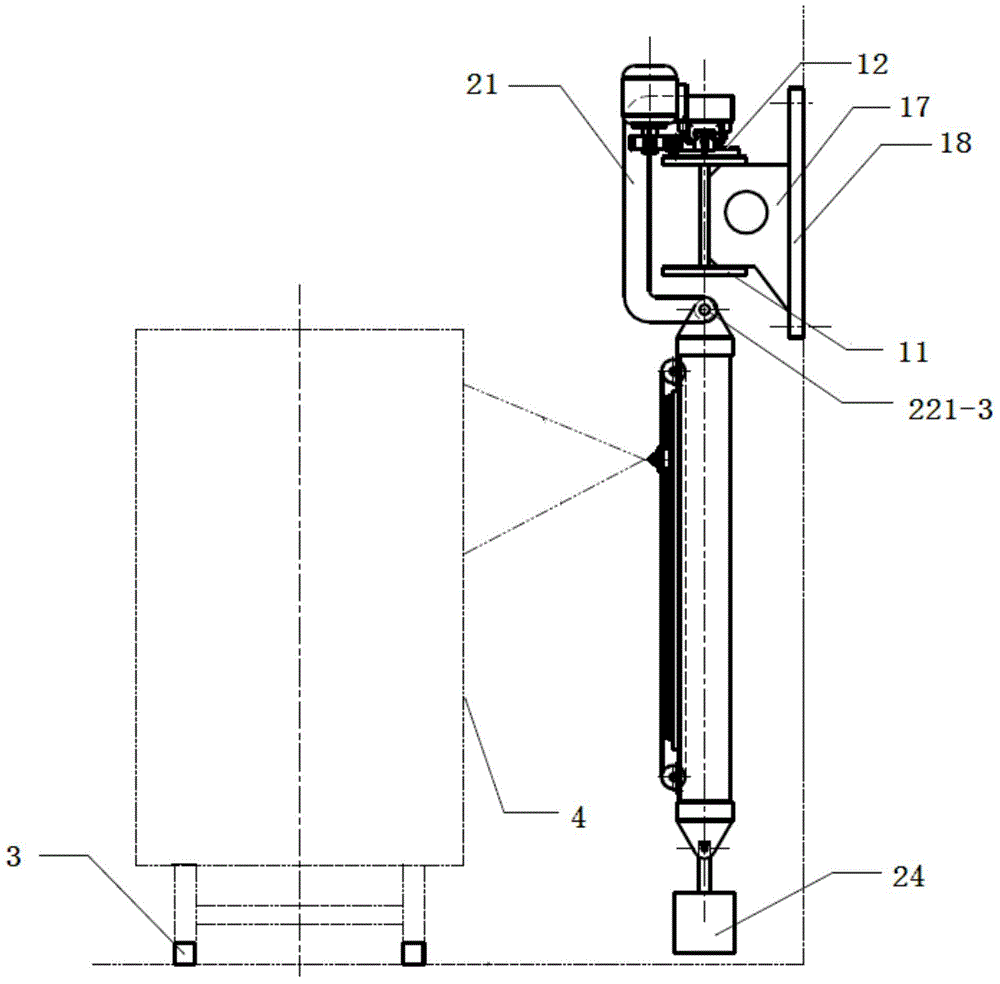

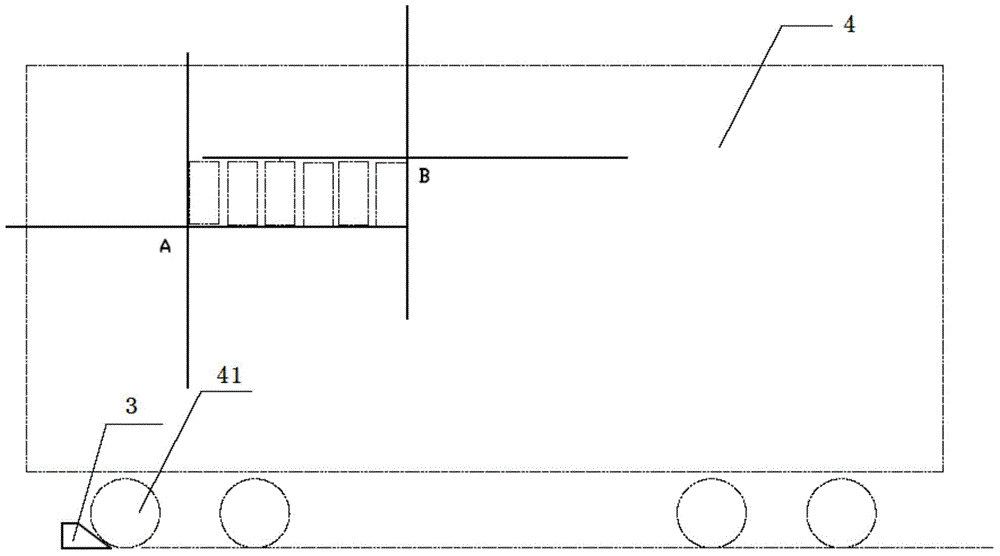

[0024] Such as Figure 1~3 As shown, the automatic positioning device for the paint marking position of railway wagons of the present invention includes a side suspension guide rail composition 1, two digitally controlled crosshair semiconductor laser positioning mechanisms 2 and several vehicle positioning blocks for fixing the wheels of railway wagons on the workshop floor 3. Each numerically controlled crosshair semiconductor laser positioning mechanism 2 includes a longitudinal movement trolley composition 21, a vertical movement mechanism composition 22, a crosshair semiconductor laser assembly 23 and a counterweight 24; the side suspension guide rail composition 1 is fixedly arranged on On the wall surface of the spraying workshop or on the cylindrical surface of the workshop, the side suspension guide rail is composed of 1 and two longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com