U-shaped bending die with shaping function

A bending mold, U-shaped technology, applied in the field of bending molds, can solve the problems of poor U-shaped parts, cumbersome operation, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

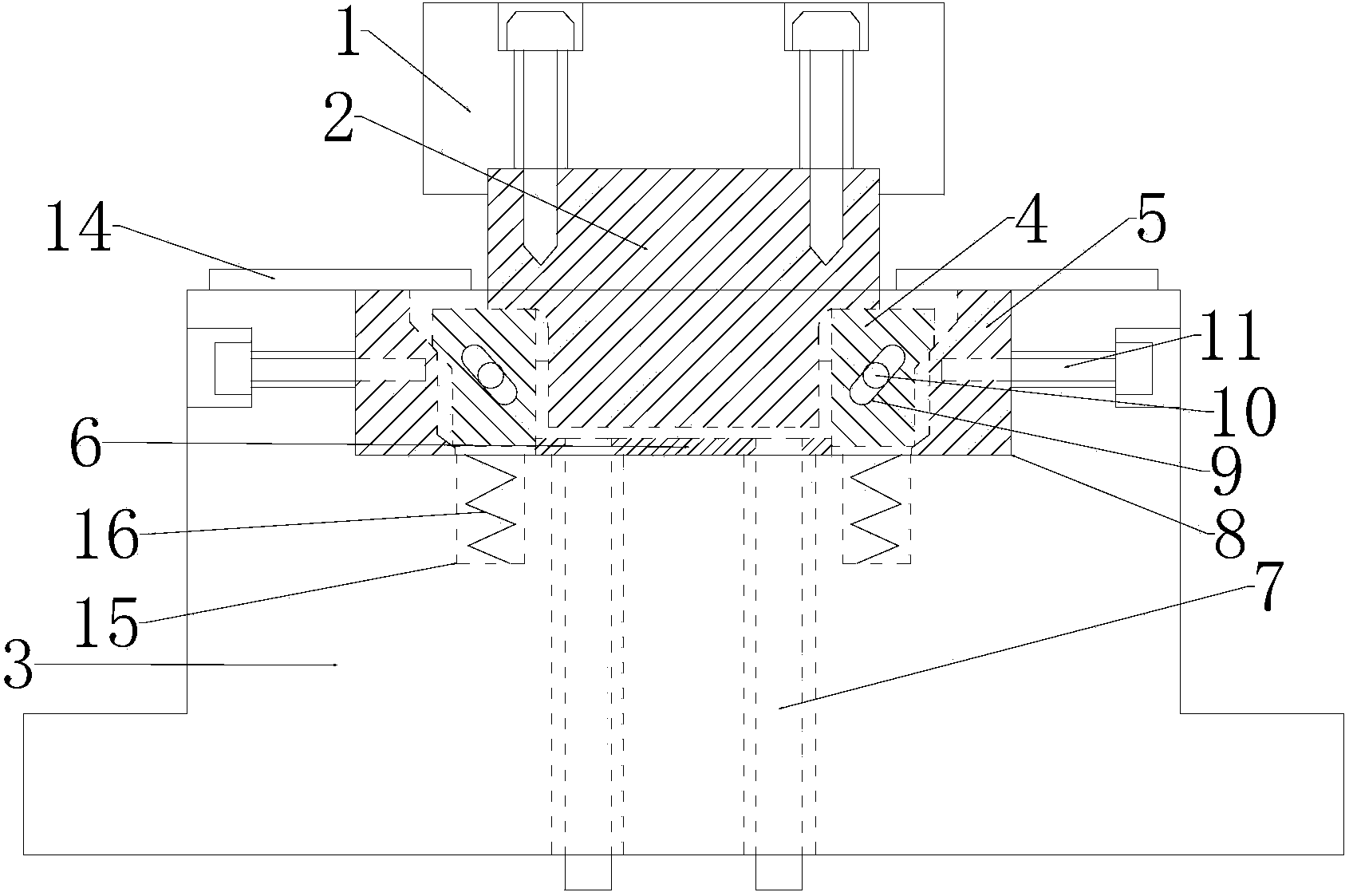

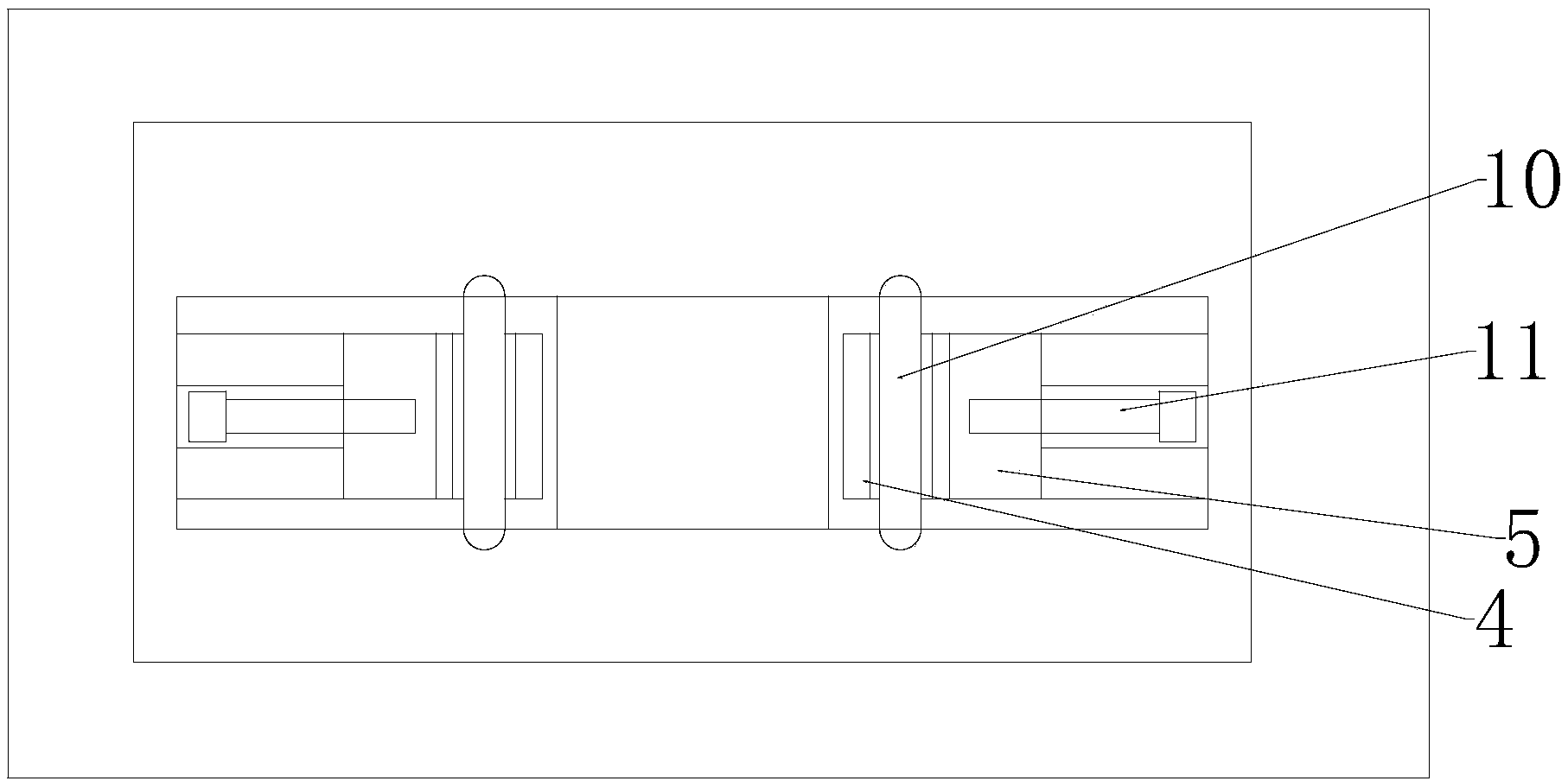

[0013] Depend on figure 1 and figure 2 It can be seen that the U-shaped bending die with shaping of the present invention comprises an upper mold base 1, a punch 2, a lower mold base 3, a die 4, a wedge 5, a top plate 6 and a guide rod 7, and the punch 2 communicates with the upper mold base. 1 is fixedly connected by screws, the lower mold base 3 is provided with a working groove 8, and the working groove 8 is provided with two symmetrical dies 4 and two wedges 5, and the wedges 5 are located in the die 4, the die 4 is in contact with the inclined wedge 5, the lower die base 3 is provided with a waist-shaped groove 9, and the die 4 is provided with a round pin 10, and the round pin 10 is constrained in the waist-shaped groove 9 Inside, a screw rod 11 is arranged on both sides of the lower mold base 3, and the screw rod 11 extends from the lower mold base 3 into the wedge 5 in the working groove 8, and a top plate 6 is arranged between the die base 4 , the lower surface of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap