Membrane electroflocculation device and method for microalgae harvesting by utilizing same

An electro-flocculation and microalgae technology, applied in chemical instruments and methods, single-cell algae, energy and wastewater treatment, etc., can solve the problems of destroying algal cells, reducing yield, and high cost of electrodes, improving flocculation rate and improving cleanliness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

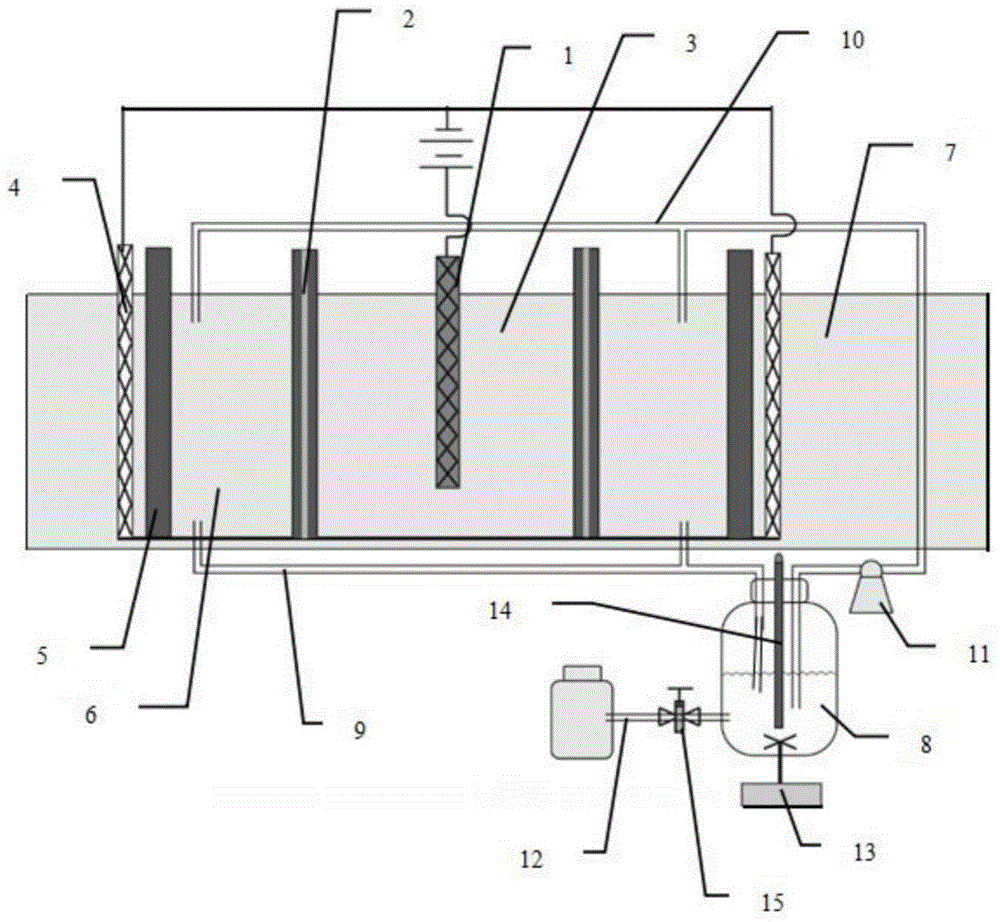

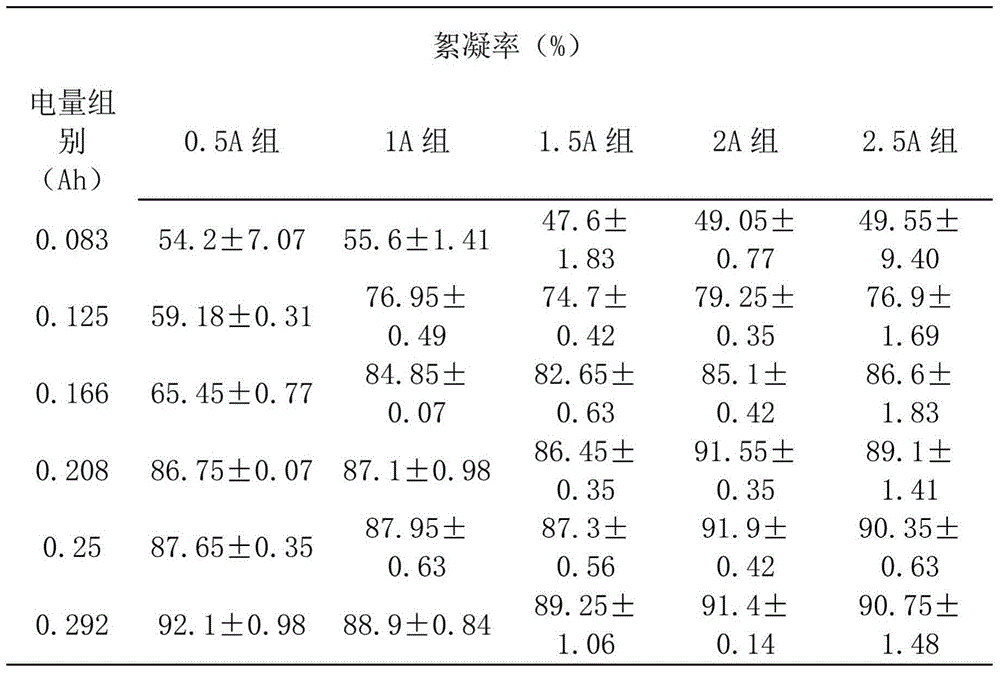

[0055] 1L-scale Microalgae Membrane Electroflocculation Harvesting

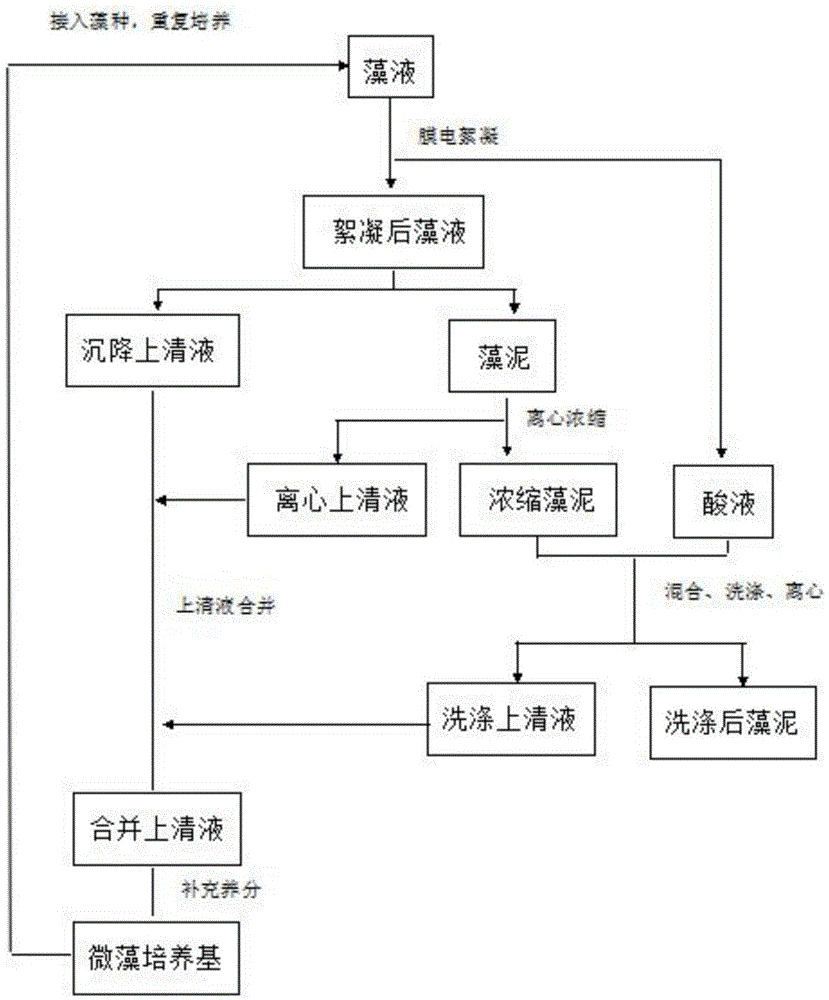

[0056] Materials and methods: The membrane electroflocculation device used in this example was figure 1 and figure 2 and formulate. Use plexiglass to prepare the fixed frame. The outer dimensions of the finished product are: 17*4*14cm (length*width*height). The device was placed in an algae pond 7 with an inner dimension of 13.5*6.5*17.5 (length*width*height). Place 100mL of 0.1M Na in anode zone 3 2 SO4 solution; 50 mL of artificial seawater with a salinity of 3% is placed in the acid chamber 6 . 1L Nannochloropsis oculata algae liquid was placed in the algae pool 7, and the biomass of the algae liquid was about 1.4g / biomass. The stainless steel mesh is used as the cathode electrode 4 , and the DSE oxygen evolution electrode is used as the anode electrode 1 . 0.5A constant current electrolysis was performed for 10min, 15min, 20min, 25min, 30min, and 35min respectively. After the electrolysis, the algal...

Embodiment 2

[0070] 150L runway pond scale microalgae membrane electroflocculation harvesting

[0071] Materials and methods: A membrane electroflocculation device was fabricated as in Example 1, and the external dimensions were: 30*5*20cm (length*width*height). The device is placed in the raceway pond algae pond 7 and is radially parallel to the water flow. A 0.1M Na2SO4 solution is placed in the anode area 3 until it is the same height as the algal liquid level; artificial seawater with a salinity of 3% is placed in the acid chamber 6 until the same level as the algal liquid level. The algae pool 7 is Nannochloropsis oculata algal fluid, and the algal fluid biomass is about 1.4g / biomass. The stainless steel mesh is used as the cathode electrode 4 , and the DSE oxygen evolution electrode is used as the anode electrode 1 . Electrolysis was performed at a constant current of 10A for 20min, 40min, 60min, 80min, 100min, 120min, 140min, and 160min, respectively. After the electrolysis, the a...

Embodiment 3

[0077] Example 3 The washing effect of membrane electroflocculation device on algae

[0078] Materials and Methods:

[0079] As in Example 1, N. oculata was harvested by electroflocculation of microalgal membranes on a 1 L scale. Using stainless steel mesh as cathode electrode 4, DSE oxygen evolution electrode as anode electrode 1, electrolysis with 2A constant current for 5min, 10min, 15min respectively, the voltage of 1L algae solution is stable between 9.9 and 10.5. After the electrolysis was completed, the pH of each part was measured. Then, the acid chamber 6 liquid and the algae liquid were mixed, the other group was not mixed, centrifuged at 10,000 rpm for 6 min, the supernatant was taken, and the calcium and magnesium ion concentrations and pH were determined by EDTA.2Na titration method. Similarly, the algal mud with two different treatments, washed and unwashed, was taken for the determination of pigment concentration, and oil extraction and determination were carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com