Efficient microbial composite flocculant and preparation method thereof

A technology of composite flocculant and high-efficiency microorganisms, which is applied in the treatment of granular microbial carriers, chemical instruments and methods, biological water/sewage treatment, etc., and can solve problems such as unstable flocculation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]A high-efficiency microbial composite flocculant, including 1 part of modified nano-ferric oxide and 100 parts of mixed bacterial liquid of Caulobacter crescentus and Klebsiella; the preparation process includes the preparation of mixed bacterial liquid, modified nano-si The preparation of ferric oxide and the preparation of high-efficiency microbial composite flocculant comprise the following steps:

[0034] 1. Preparation of activated bacterial liquid:

[0035] S1: Prepare medium: weigh 20g of glucose, 2g of peptone, 2g of potassium dihydrogen phosphate, 5g of dimethyl hydrogen phosphate, 0.2g of ammonium sulfate, 0.2g of magnesium sulfate heptahydrate, 0.5g of urea, and 0.5g of yeast extract, dissolve in In bacterial water, adjust the pH to 7.0, quantify the sterile water to 1000mL; sterilize at 121°C for 20min.

[0036] S2: Inoculation culture: inoculate the strains of C. crescentus and Klebsiella in S1 medium respectively, culture them in a shaker at 30°C and 150r / ...

experiment example 1

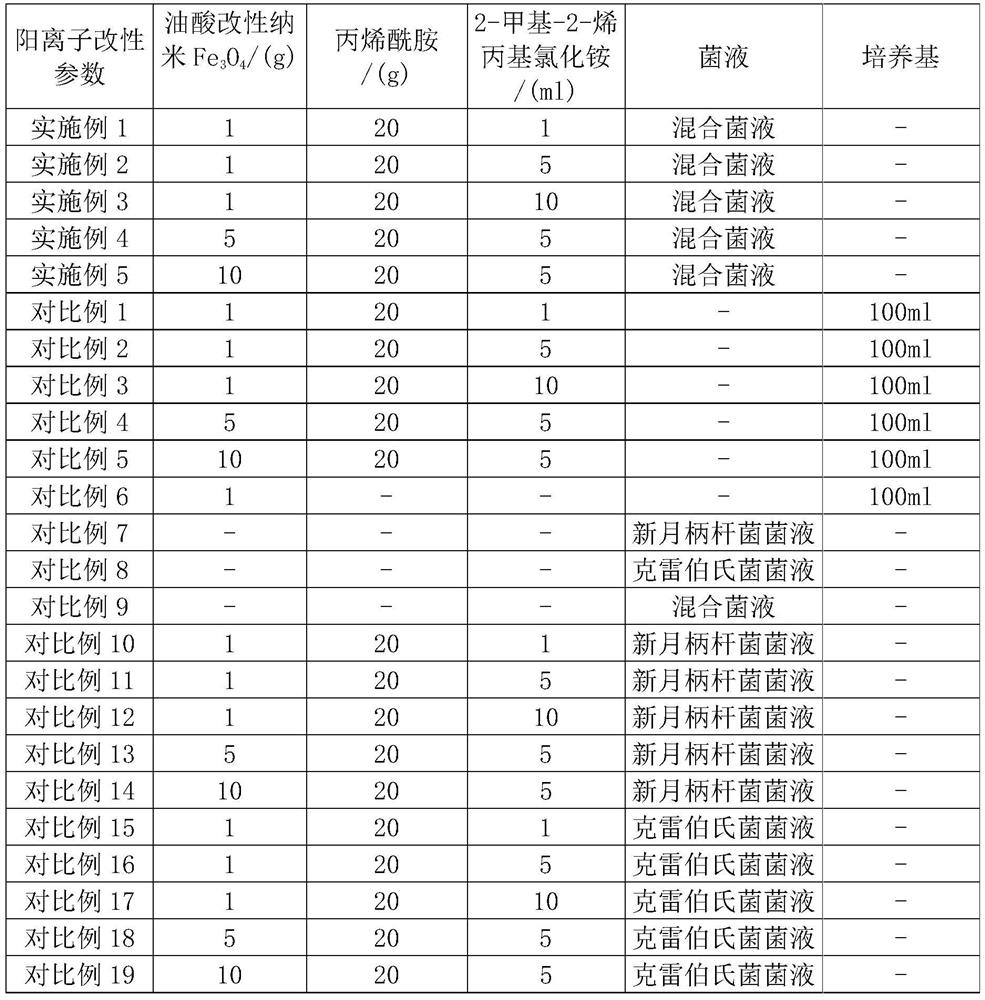

[0051] Experimental example 1: Flocculation effect of modified nano ferric oxide

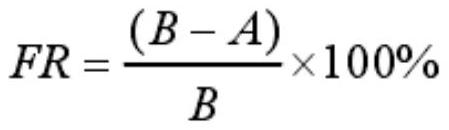

[0052] Prepare 5g / L kaolin suspension, after stirring evenly, get 100ml respectively and put it in seven 100ml beakers, add 0.5ml10% calcium chloride solution, add flocculant according to the concentration of 10g / L respectively (comparative examples 1~6), Add sterile water as a blank control, stir rapidly for 1 min, and then stir slowly for 1 min after an interval of 2 min, and let it stand for 30 min. Take the supernatant and measure the absorbance at the wavelength λ=550 nm of the spectrophotometer. The calculation formula of flocculation rate:

[0053]

[0054] In the formula: FR is the flocculation rate; A is the absorbance of the water sample added with flocculant after standing; B is the absorbance of the water sample added with sterile water after standing. The experimental results are shown in Table 2.

[0055] Table 2 Comparison of flocculation rates of different modified nano-ferr...

experiment example 2

[0059] Experimental Example 2: Flocculation Effect of Klebsiella and Crescent Bacteria

[0060] According to 0.5%, 1%, 2%, and 4% of the mass volume of the test kaolin suspension, the Klebsiella bacterium liquid and the Crescent bacillus bacterium liquid were mixed according to a 1:1 ratio to obtain a mixed bacterium liquid. The flocculation rate of the mixed bacterial solution was determined according to the method shown in Experimental Example 1, and the experimental results are shown in Table 3.

[0061] Table 3 Comparison of flocculation rates of different bacterial solutions

[0062]

[0063] The experimental results show that when the addition amount of the two bacterial solutions in the microbial flocculant is too low (addition ratio ≤ 0.5%), the flocculation effect of the individual bacterial solution and the mixed bacterial solution is not significant, and when the addition ratio of the two bacterial solutions is When the concentration is 1% to 4%, the flocculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com