Production system and production method of machine-made gravels

A technology of production system and production method, which is applied in the field of construction machinery, can solve the problems of poor aggregate particle shape and high demand for machine-made sand and gravel, and achieve the effect of improving quality and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

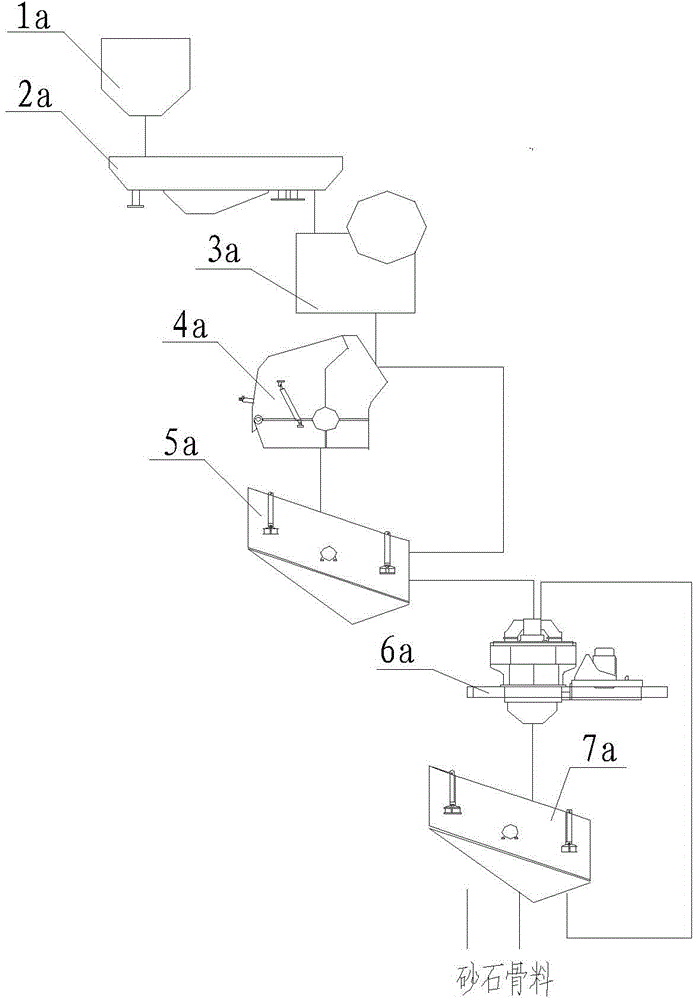

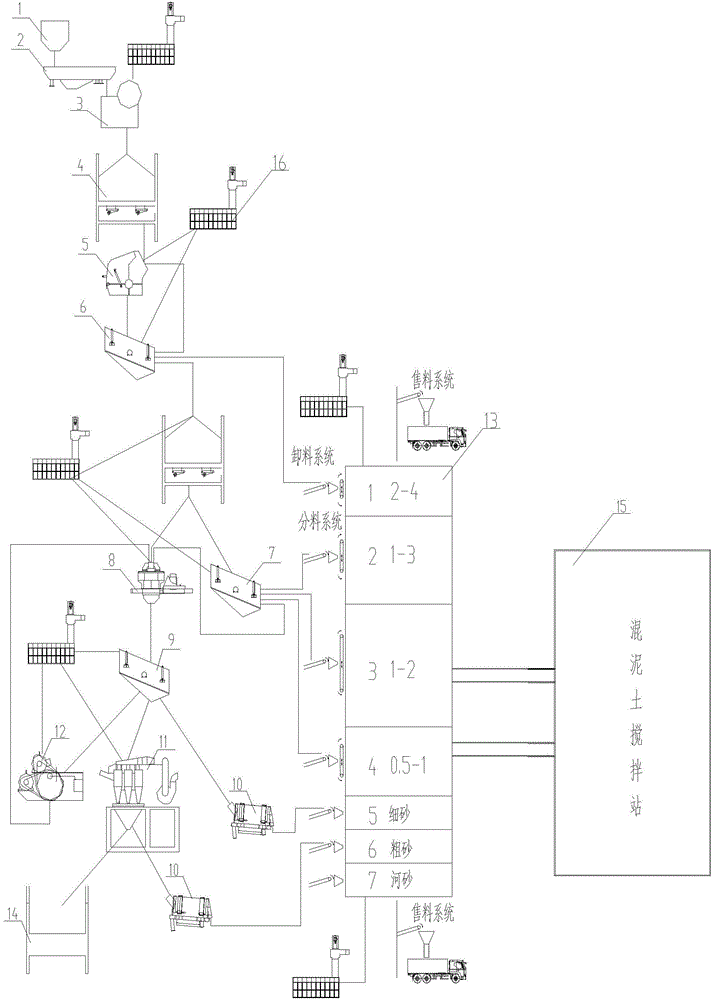

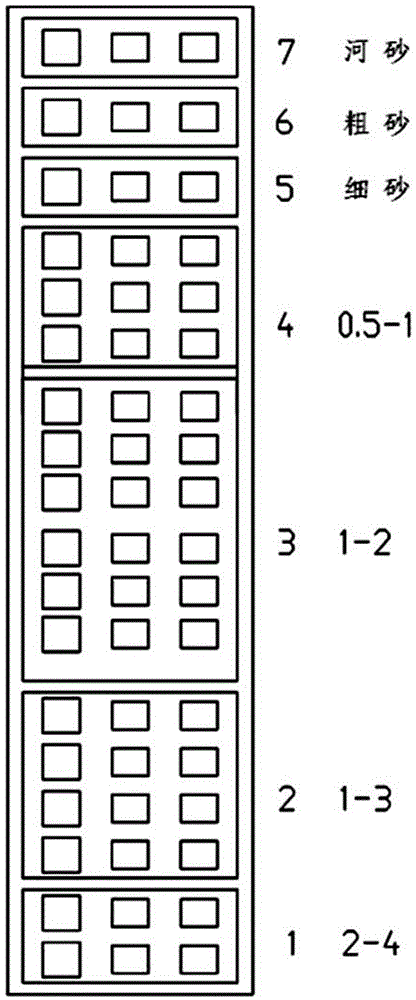

[0038] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0039] In the process of practical application, the inventor noticed that the quality of the finished sand and gravel produced by the mechanism-made sand and gravel production system of the prior art is not good, mainly reflected in the poor grain shape of the aggregate, and many grain sizes do not meet the requirements, so it is unqualified This is mainly because there are more needle flake particles in the aggregate after coarse crushing, medium crushing and sand making machine crushing. Too many needle flake particles will make the workability of concrete worse and the strength Reduced; moreover, the existing system produces more sand and gravel in a certain particle size range, which has a certain deviation from the particle size range with larger demand. Even if cyclic crushing is carried out, the particle size an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com