Lens group and light source device using same

A lens group and lens technology, applied in the direction of lens, light source, electric light source, etc., can solve the problems of not being able to completely eliminate the bright spots of the light field and reduce the overall light output effect, and achieve the effects of uniform light field distribution, energy reduction, and elimination of bright spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

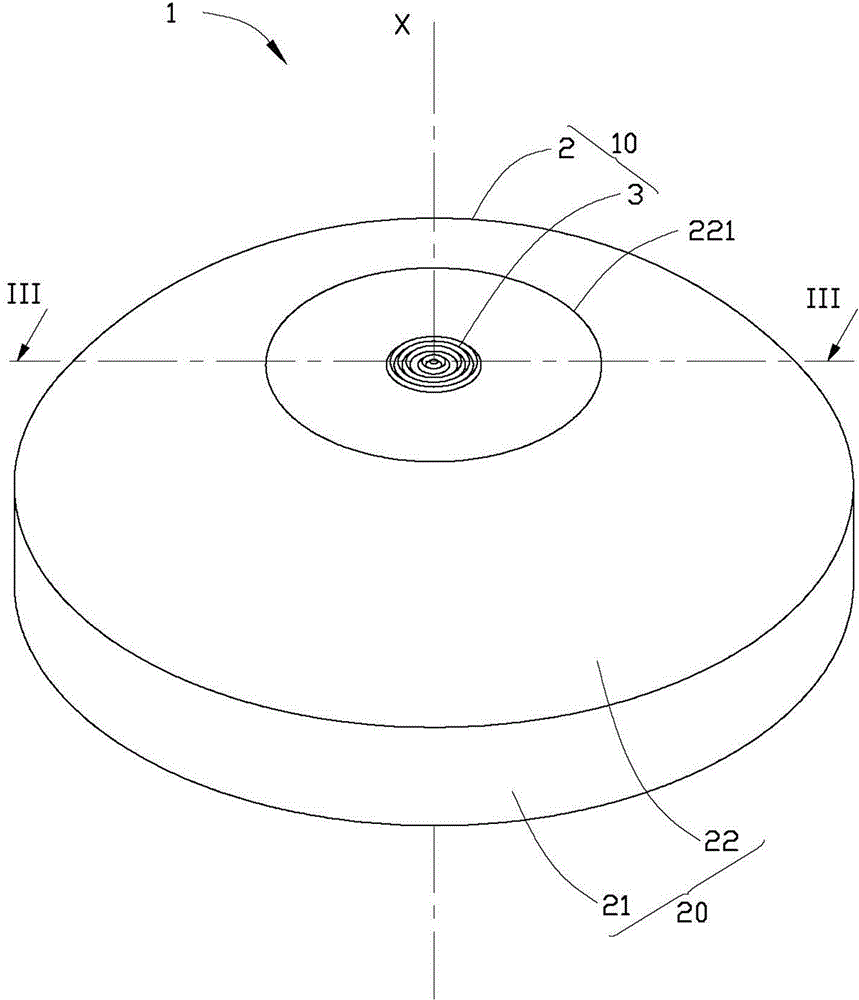

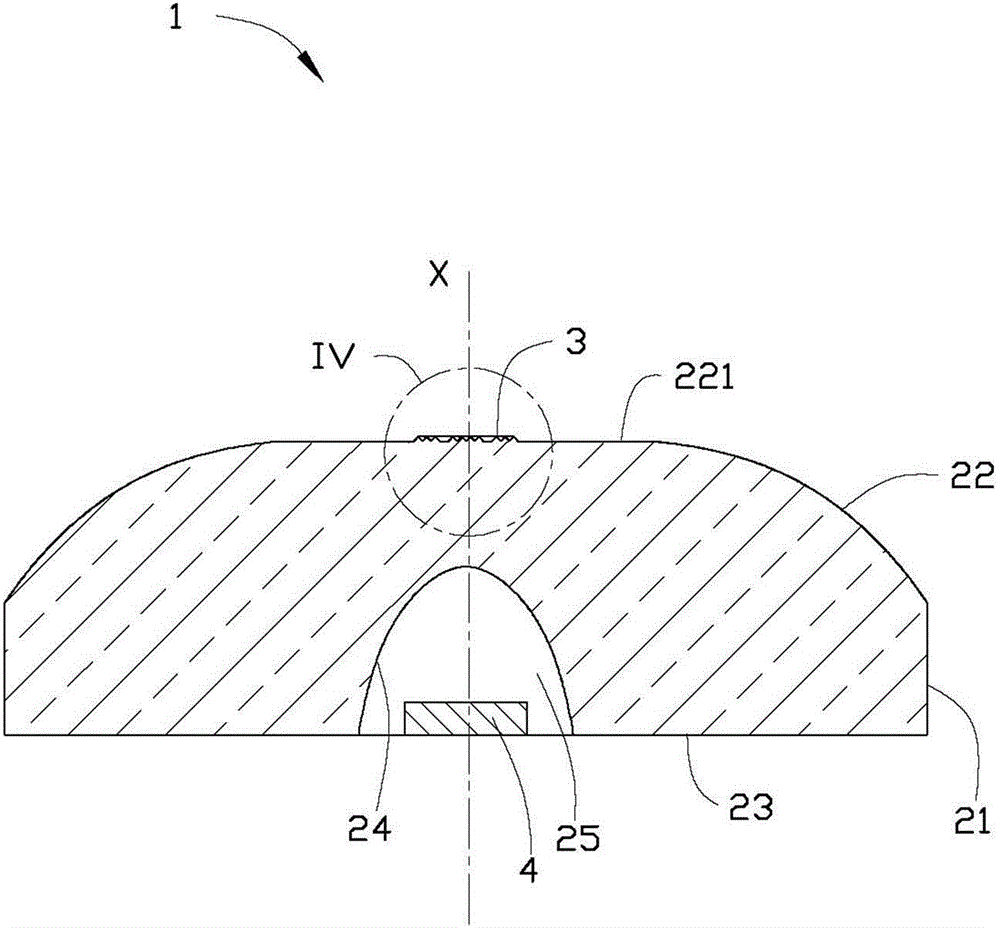

[0018] see Figure 1 to Figure 3 , the light source device 1 of the first embodiment of the present invention includes an LED light source 4 and a lens group 10 matched with the LED light source 4 . The lens group 10 includes a lens 2 and a micro-lens group 3 on top of the lens 2 . The microlens group 3 includes a plurality of ring-shaped microlens units 31 , and these ring-shaped microlens units 31 are arranged on the top of the lens 2 in circles from inside to outside. Among the light emitted by the LED light source 4 , the light near the optical axis enters the lens 2 and is scattered out of the lens group 10 through the micro-lens group 3 on the top of the lens 2 .

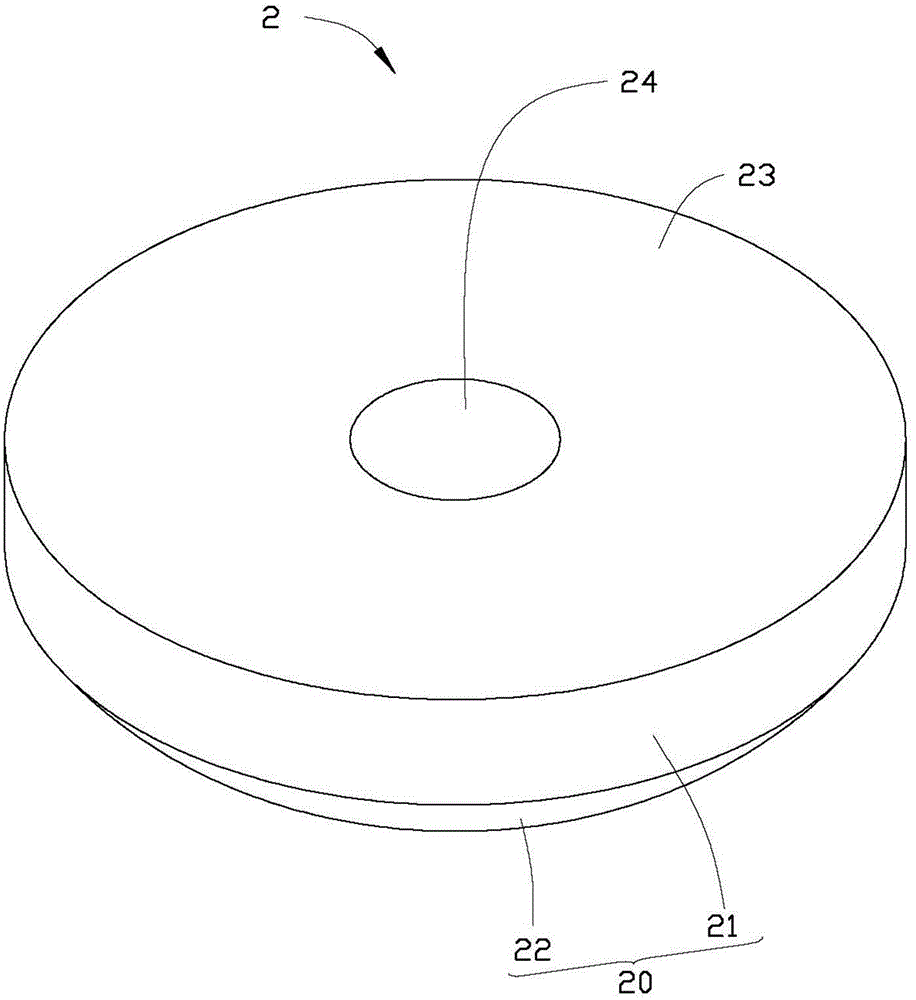

[0019] The lens 2 includes a light incident surface 24 and a light exit surface 20 opposite to the light incident surface 24 . The lens 2 has a central axis X passing through the lens 2 . The light incident surface 24 of the lens 2 is symmetrical to the central axis X of the lens 2 , and the light outgoing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com